Combined workbench for electric soldering iron

A technology of electric soldering iron and workbench, which is applied in the direction of soldering iron, manufacturing tools, metal processing equipment, etc. It can solve the problems of auxiliary items occupying working time, surrounding items are scalded, and placement restrictions, etc., so as to achieve simple structure, avoid burns, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

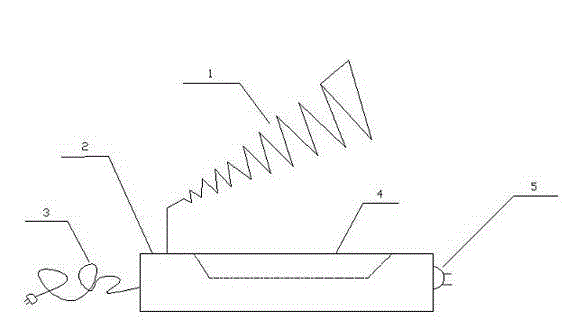

[0008] Such as figure 1 As shown, the present invention is composed of an electric soldering iron shelf 1, a base 2, a power plug 3, an auxiliary material box 4 and a power socket 5, the base 2 is a rectangular box made of insulating bakelite, and the electric soldering iron shelf 1 and the auxiliary material box 4 are installed on the base 2 respectively, and the power plug 3 and the power socket 5 are respectively arranged on both sides of the base 2, and the wire of the power plug 3 passes through the base 2 to connect with the power socket 5, and the power plug 3 is used for external power supply, power socket 5 is used for the power socket of electric soldering iron, and electric soldering iron shelving frame 1 is made of 50crVA material, and electric soldering iron shelving frame 1 is a conical spring, and the bottom diameter of this conical spring is 35mm, long 200mm inclined and fixed on the base 2; the auxiliary material box 4 is made of δ1.5mm stainless steel plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com