Ultrasonic welding device and ultrasonic welding method for controlling continuous ultrasonic welding processes

An ultrasonic and processing device technology, applied in the field of continuous ultrasonic welding process, can solve the problems of no longer bonding force of seams, unsatisfactory welding effect, and difficulty in achieving uniform quality of welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

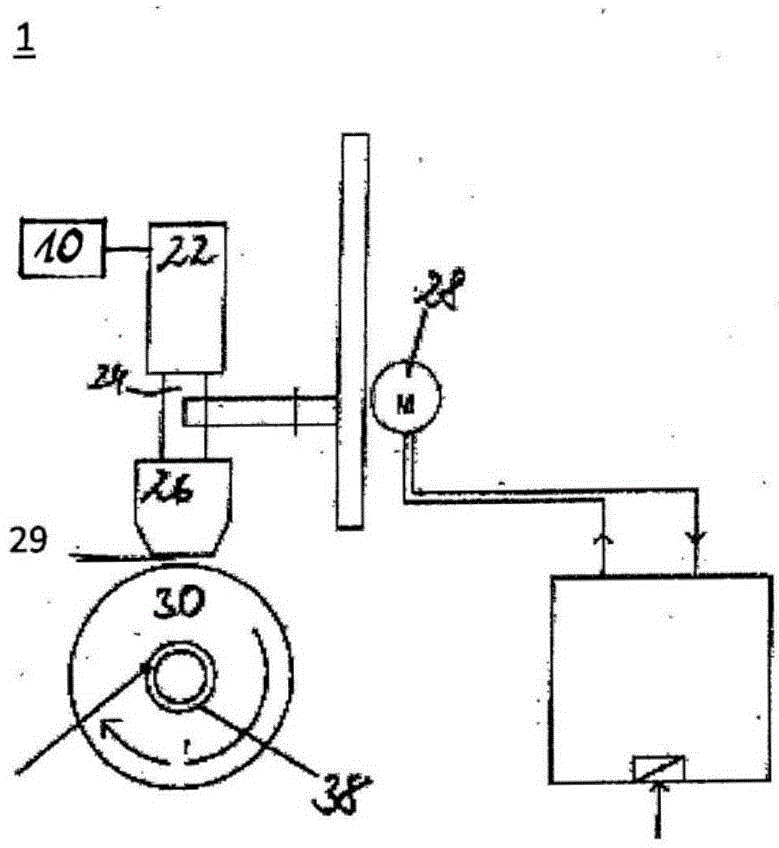

[0041] figure 1 The basic structure of an ultrasonic processing device 1 is shown. The ultrasonic processing device 1 comprises a sonotrode 10, a converter 22, a booster 24, a linearly movable sonotrode 26, and a roller or an anvil 30 used as a reverse tool respectively, the sonotrode 26 and the roller Between 30 gaps 29 are formed.

[0042] By simulating the structure of the above-mentioned ultrasonic processing device 1, it can be known that a better option is to provide a rotatable sonotrode (not shown in the figure). In this case, at least one sonotrode is arranged on the roller. The sonotrode roller is carried or supported rotatably about a central axis. The outer region of the sonotrode roller has the function of the outer surface of the roller 30, which will be described in detail below. In order to adjust the gap between the rotating sonotrode roller and the anvil arranged opposite it, the sonotrode roller and / or the anvil (not shown) can be moved linearly. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com