Supersonic nozzle for miniature ink jet printing

A supersonic nozzle and micro-injection technology, which is applied in the direction of additive processing, etc., can solve the problems of poor jet convergence at the nozzle outlet, short distance in the supersonic section, and large flow, so as to prevent clogging, reduce air flow, and reduce The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

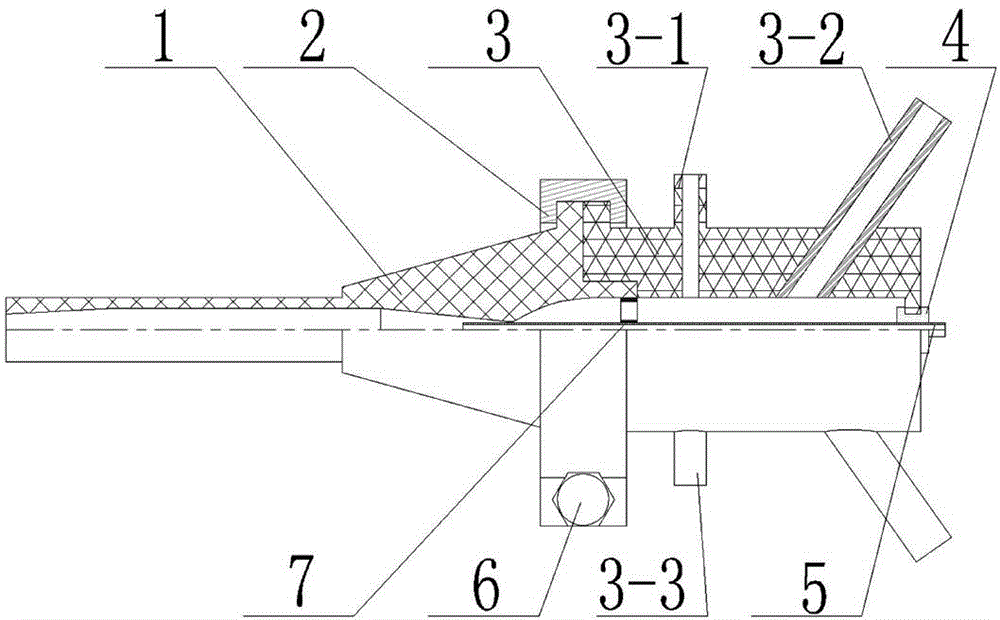

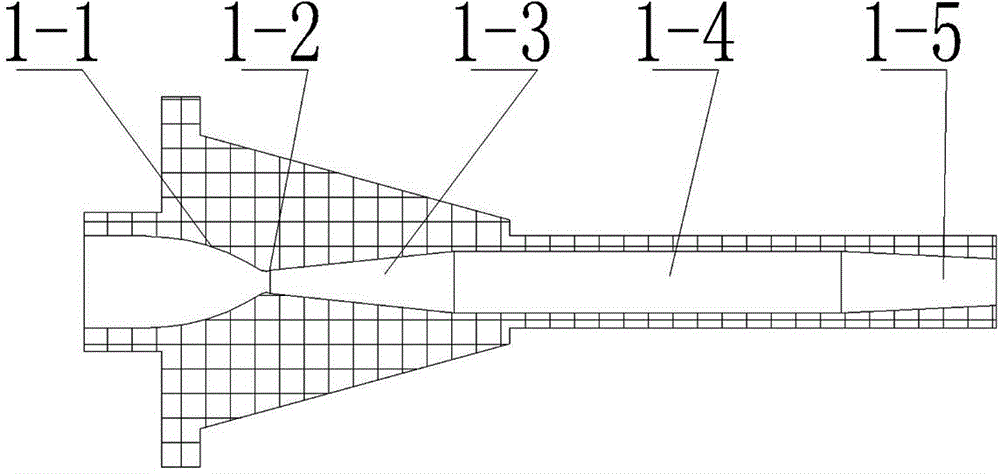

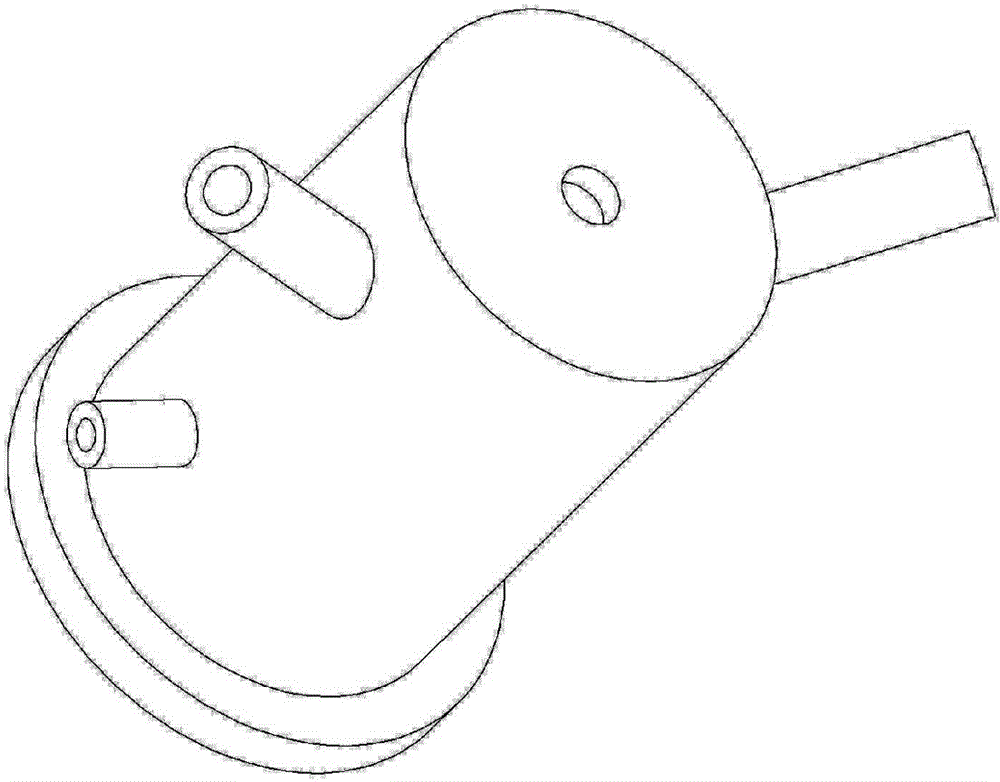

[0031] Such as Figure 1-6 As shown, it is a schematic structural diagram of a supersonic nozzle for micro-jet printing, which mainly includes a Laval nozzle 1, a locking block 2, an air chamber body 3, a pressure probe interface 3-1, and an air source inlet 3 -2. Temperature probe interface 3-3, U-shaped plug 4, powder feeding pipe 5, fastening bolt 6, ring grid 7, Laval nozzle 1 and gas chamber body 3 are connected by locking block 2 to form an axisymmetric whole , and fixed by fastening bolts 6, the front end of the gas chamber body 3 is symmetrically distributed with pressure probe interfaces 3-1 and temperature probe interfaces 3-3, and the end of the gas chamber body 3 is symmetrically inserted obliquely with multiple gas source inlets 3 -2, the tail is equipped with a coaxial powder feeding pipe 5 through a U-shaped plug 4, and an annular grid 7 is arranged at the contact point between the Laval nozzle 1 and the gas chamber body 3, and the high-pressure gas and powd...

Embodiment 2

[0038] A supersonic nozzle for microjet printing, which mainly includes a Laval nozzle 1, a locking block 2, an air chamber body 3, a pressure probe interface 3-1, an air source inlet 3-2, and a temperature probe interface 3 -3, U-shaped plug 4, powder feeding pipe 5, fastening bolt 6, ring grid 7, the Laval nozzle 1 and the gas chamber body 3 are connected into an axisymmetric whole through the locking block 2, and the fastening bolt 6 is used Fixed, pressure probe interface 3-1 and temperature probe interface 3-3 are symmetrically distributed up and down the front end of the gas chamber body 3, multiple gas source inlets 3-2 are inserted symmetrically and obliquely at the end of the gas chamber body 3, and the tail passes through a U-shaped The plug 4 is equipped with a coaxial powder feeding pipe 5, and an annular grid 7 is arranged at the contact point between the Laval nozzle 1 and the gas chamber body 3, and the high-pressure gas and powder are gathered and sprayed ou...

Embodiment 3

[0043] A supersonic nozzle for microjet printing, which mainly includes a Laval nozzle 1, a locking block 2, an air chamber body 3, a pressure probe interface 3-1, an air source inlet 3-2, and a temperature probe interface 3 -3, U-shaped plug 4, powder feeding pipe 5, fastening bolt 6, ring grid 7, the Laval nozzle 1 and the gas chamber body 3 are connected into an axisymmetric whole through the locking block 2, and the fastening bolt 6 is used Fixed, pressure probe interface 3-1 and temperature probe interface 3-3 are symmetrically distributed up and down the front end of the gas chamber body 3, multiple gas source inlets 3-2 are inserted symmetrically and obliquely at the end of the gas chamber body 3, and the tail passes through a U-shaped The plug 4 is equipped with a coaxial powder feeding pipe 5, and an annular grid 7 is arranged at the contact point between the Laval nozzle 1 and the gas chamber body 3, and the high-pressure gas and powder are gathered and sprayed ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com