A kind of photo paper-cut and its production method

A production method and photo technology, applied in special patterns, decorative arts, patterns characterized by outlines, etc., can solve the problems of many superimposed layers, cumbersome production process, rough production method, etc., to achieve bright colors and simplified production methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

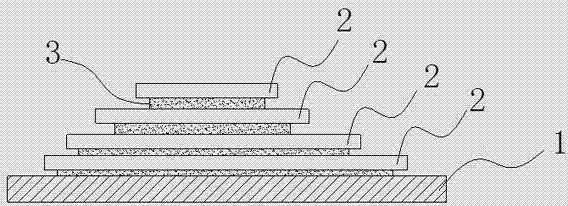

[0027] Such as figure 1 and figure 2 Shown, a kind of landscape painting paper-cut production method comprises the following steps:

[0028] a. Pattern preprocessing: select the landscape picture to be made, and use Photoshop computer software to preprocess the size and color of the landscape picture to form the master picture. The Photoshop software is developed by Adobe Systems software company in the United States;

[0029] b. Making the substrate: cutting and trimming the substrate substrate to make a substrate for paper-cutting and pasting, and preparing paper for cutting and engraving. In this embodiment, the substrate is a solid-color wood board;

[0030] c, layering: divide the mother picture into four sub-pictures according to the chromaticity and gradient degree of the color of the main picture through Photoshop computer software, each sub-picture includes at least one continuous pattern 3, and the color in each sub-picture There is a gradual relationship with eac...

Embodiment 2

[0037] A method for making paper-cut portraits of people, comprising the following steps:

[0038] a. Pattern preprocessing: select the figure portrait picture to be produced, and use Photoshop computer software to preprocess the size and color of the landscape picture to form the master picture;

[0039] b, make the substrate: the substrate substrate is cut and trimmed to make a substrate for paper-cutting and pasting, and prepare rice paper for cutting and engraving; in this embodiment, the substrate is a solid color plank, and the substrate Made with a frame, sprayed with photosensitive color-changing paint on the frame;

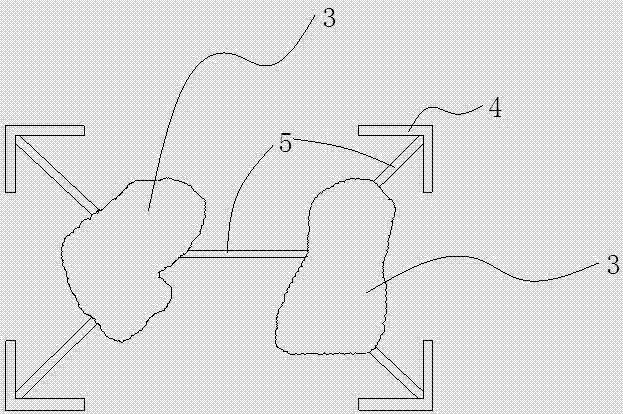

[0040] c, layering: divide the master picture into six sub-pictures according to the chromaticity and gradient degree of the color of the mother picture through Photoshop computer software, such as figure 2 As shown, each sub-figure includes two continuous patterns 3, and the colors in each sub-figure have a gradual relationship with each other, and the...

Embodiment 3

[0048] A photo paper-cut made by the method in the second embodiment is mainly composed of a substrate and six layers of paper-cut pasted on the substrate layer by layer. The six layers of paper-cut are all provided with patterns 3, and the substrate is formed with a frame. The frame and pattern 3 are sprayed with photochromic paint and photochromic ink respectively, and green luminous powder is added to both the photochromic paint and the photochromic ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com