Eccentric compression type thin film sample holder

A sample holder and film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of not being able to apply bias voltage and rotation at the same time, and achieve insulation problems, simple structure and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

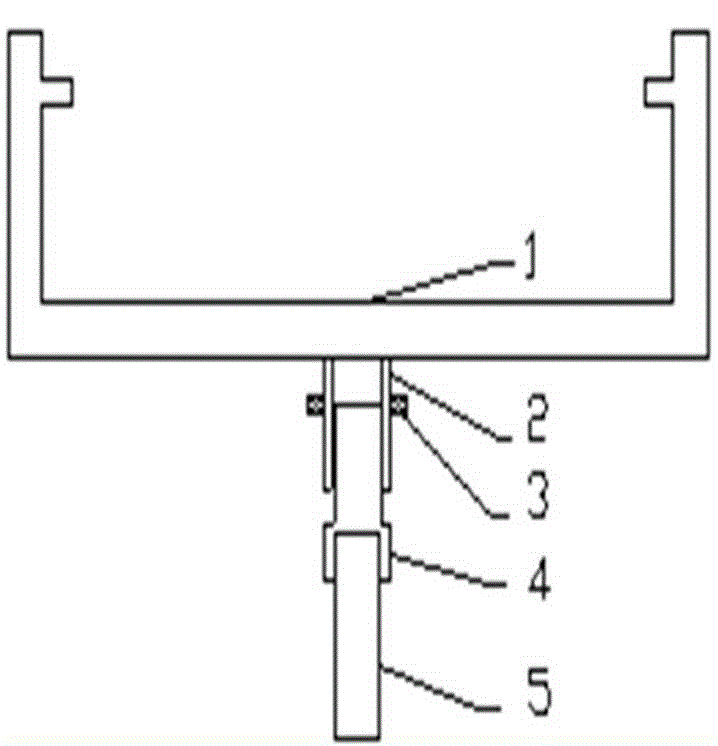

[0012] figure 1 It is a structural schematic diagram of the biasable film sample holder of the present invention. exist figure 1 Among them, the sample rack of the present invention includes a bracket 1, a bracket base 2, a metal bearing 3, a connecting rod 4 and a vacuum chamber base 5; the connection relationship is that the bracket 1 is fixedly connected to the bracket base 2, so The connecting rod 4 is arranged below the bracket base 2, one end of the connecting rod 4 is fixedly connected with the bracket 1, and the other end is fixedly connected with the vacuum chamber base 5; the inner ring of the metal bearing 3 is fixed on the connecting rod 4 , the outer ring is connected with the cable. The material of bracket 1 is polytetrafluoroethylene. In this way, the difficult problem of connecting the rotating bracket 1 and the electrode is solved, and the insulation problem of the electrode and the casing is also realized.

[0013] The bracket 1, the bracket base 2, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com