Electrostatic spraying device

A technology of electrostatic spraying and high-voltage electrostatic generation, which is applied in the direction of electrostatic spraying devices, spraying devices, spray discharge devices, etc., can solve the problems of unsatisfactory personal use, troublesome operation, and difficulty in carrying, and achieve directional deposition and directional spraying, equipment The overall volume and weight are reduced, and the effect of avoiding stabbing the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

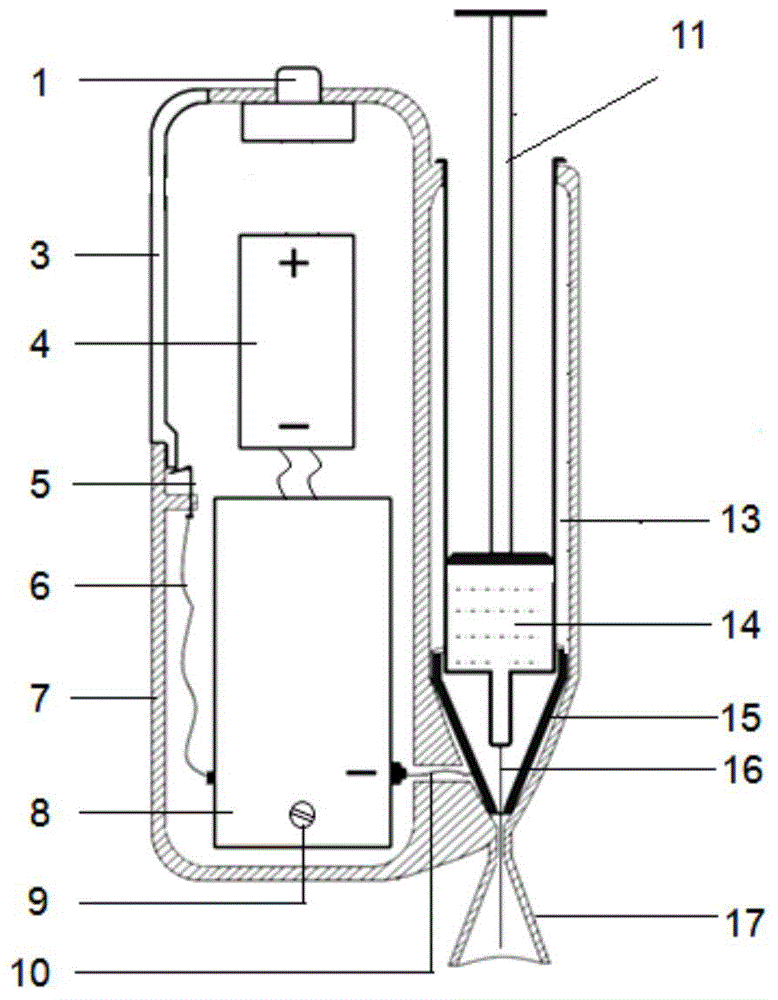

[0026] The first embodiment of the present invention relates to an electrostatic spraying device, the structure of which is as attached figure 1 As shown, specifically, the electrostatic spraying device includes a housing 7 and a cavity 13 which is arranged on the outer wall of the housing 7 and has openings at both ends. The housing 7 and the cavity 13 are all insulated. In this embodiment , the housing 7 and the cavity 13 are made of plastic.

[0027] In the inside of the housing 7, a high-voltage static electricity generating module 8 and a battery 4 that is connected to the high-voltage static electricity generating module 8 and used to supply power to the high-voltage static electricity generating module 8 are provided, and a precision potentiometer 9 is arranged on the high-voltage static electricity generator module 8 , the precision potentiometer 9 can be used to adjust the output voltage of the high-voltage electrostatic generator module 8 (DC2kV~DC30kV, the general v...

no. 2 approach

[0031] The second embodiment of the present invention relates to an operation method and a spraying process of electrostatic spraying or electrostatic spinning using the electrostatic spraying device of the first embodiment.

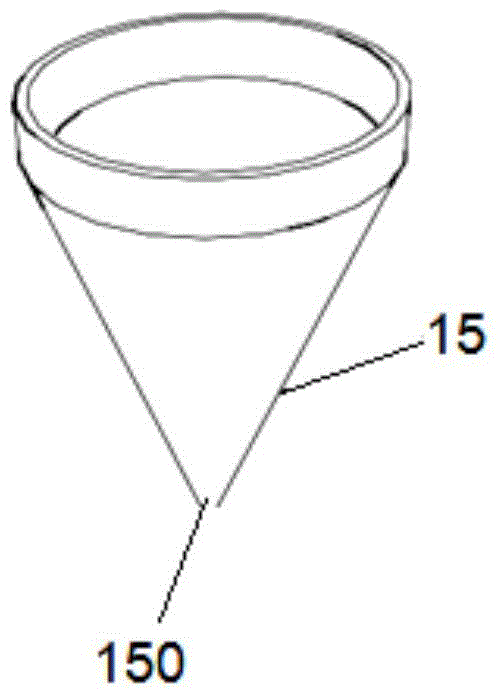

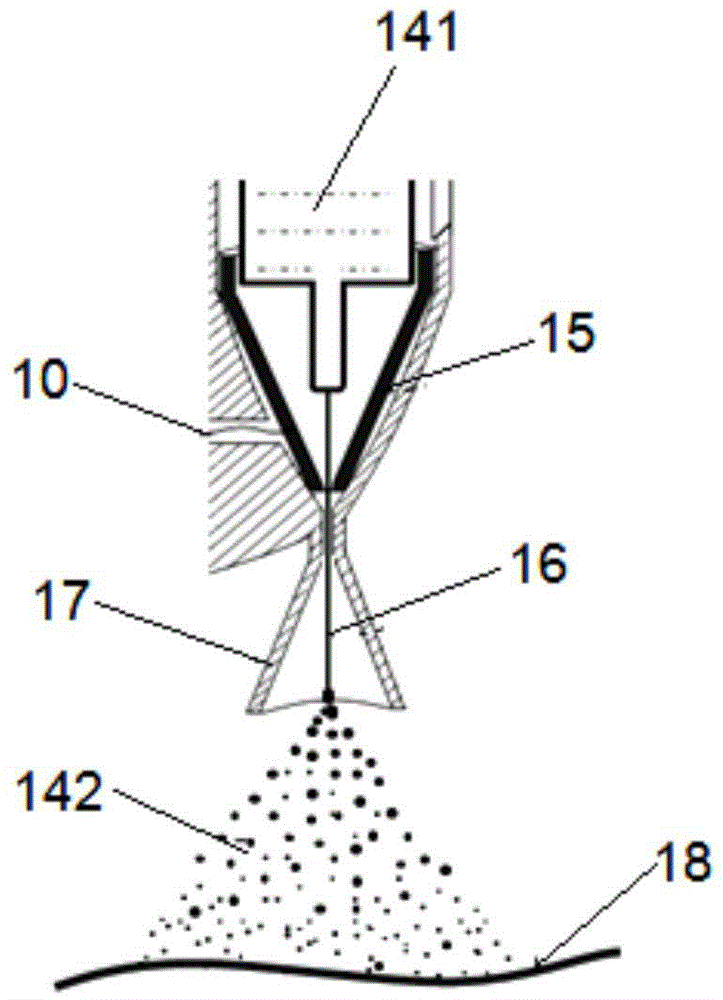

[0032] Draw an appropriate amount of spray solution into the syringe 11, turn the needle upside down, push it up, squeeze out the internal air bubbles, clean the needle 16 and insert it into the cavity 13 from top to bottom; turn on the push switch 1, the battery 4 starts to supply power, and high-voltage static electricity occurs The generator module 8 starts to work, and the negative high-voltage output line 10 transmits the high-voltage static electricity from the high-voltage electrostatic generator module 8 to the metal piece 15. Since the metal piece 15 is in contact with the needle 16 of the syringe 11, the needle 16 will be charged with a large amount of charge.

[0033] The operator holds the above-mentioned spraying device and touches the metal ...

no. 3 approach

[0038] The electrostatic spraying device according to the third embodiment of the present invention has the structure as attached Figure 5 As shown, specifically, on the basis of the first embodiment, the electrostatic spraying device of this embodiment adds a transparent observation area on the side wall of the cavity 13. In this embodiment, the transparent observation area can be A suitable transparent viewing panel 12 .

[0039] Add a transparent observation plate 12 on the side wall of the cavity 13, then the usage amount and remaining amount of the solution in the syringe 11 can be monitored in real time through the transparent observation plate 12, so that the electrostatic spraying process can be grasped at any time, and the spraying solution can be added in time Or replace the syringe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com