Lowly arranged wire structure used in medium-low speed magnetic levitation traffic engineering fill section

A technology for traffic engineering and low-lying lines, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems that the subgrade structure cannot be applied to maglev traffic engineering, and the embankment form is not suitable for medium and low-speed maglev traffic subgrade projects, etc., to achieve Avoid the unevenness of the rail surface, increase the overall stability, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

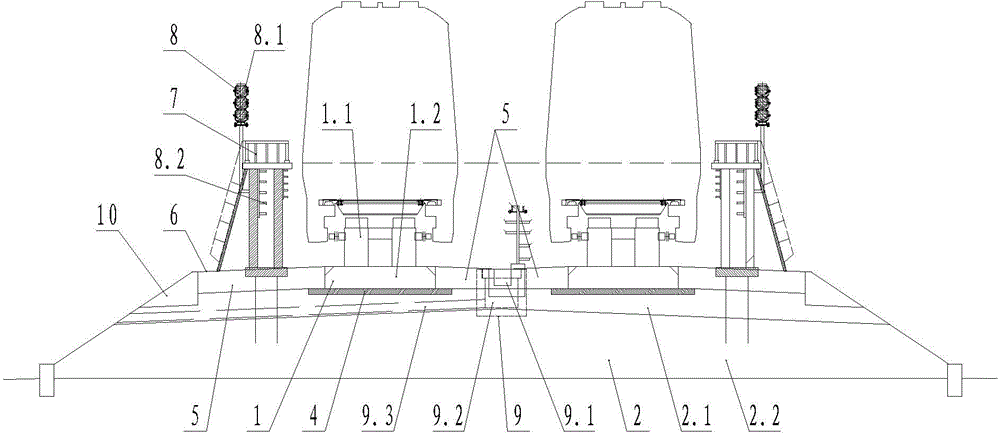

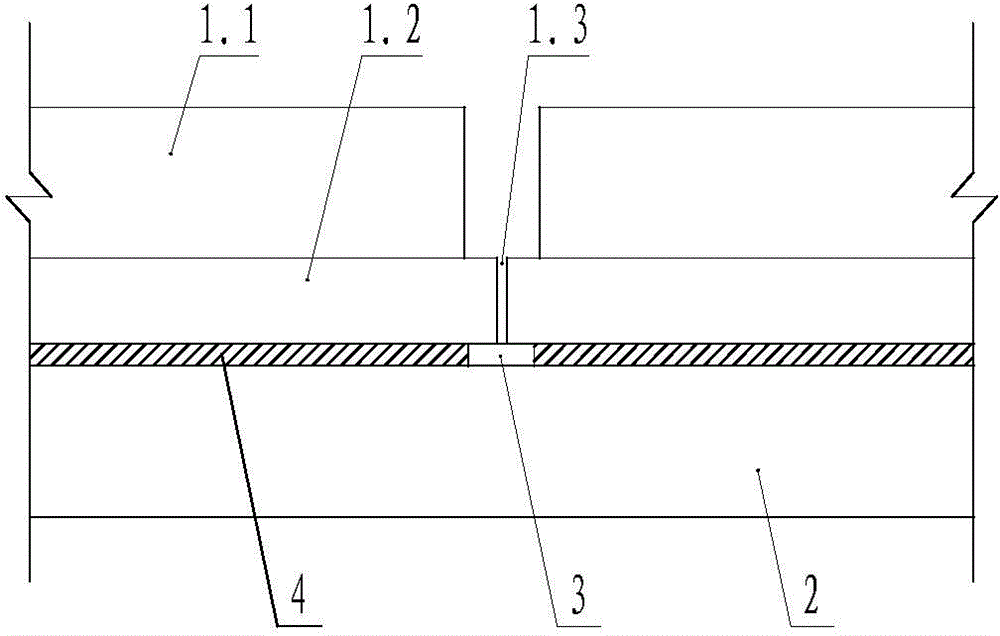

[0023] Such as figure 1 , figure 2 As shown, the present invention mainly consists of a rail-bearing beam 1, a soil-filled subgrade structure 2, an internode error-proof platform 3, a cushion layer 4 under a rail-bearing beam, a backfill protection layer 5 for a rail-bearing beam, a waterproof sealing layer 6, and an evacuation platform 7 , ancillary structure interface system 8, inter-line drainage system 9 and shoulder guard 10.

[0024] The rail bearing beam 1 is evenly arranged along the advancing direction of the line, including the track and guide rail support structure 1.1 and the bottom plate 1.2 at the bottom of the track and guide rail support structure 1.1. In the cross-sectional direction, the width of the bottom pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com