Swash plate type mortar sucking and discharging spraying pasting machine

A swash plate type, plastering machine technology, applied in the direction of construction, building construction, etc., can solve problems such as falling off, hollowing or insufficient mortar viscosity, and achieve the effect of simple structure, high risk and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0017] figure 1 and figure 2 constitute specific embodiments of the invention.

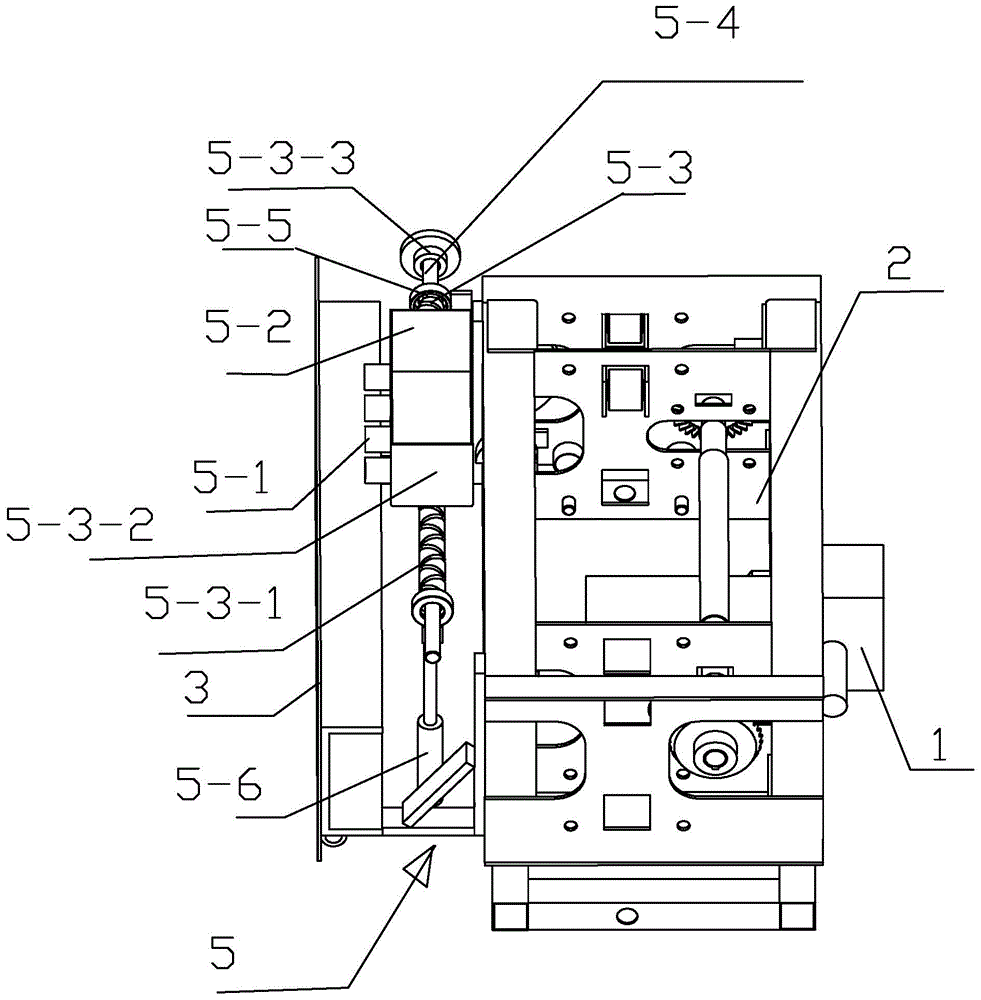

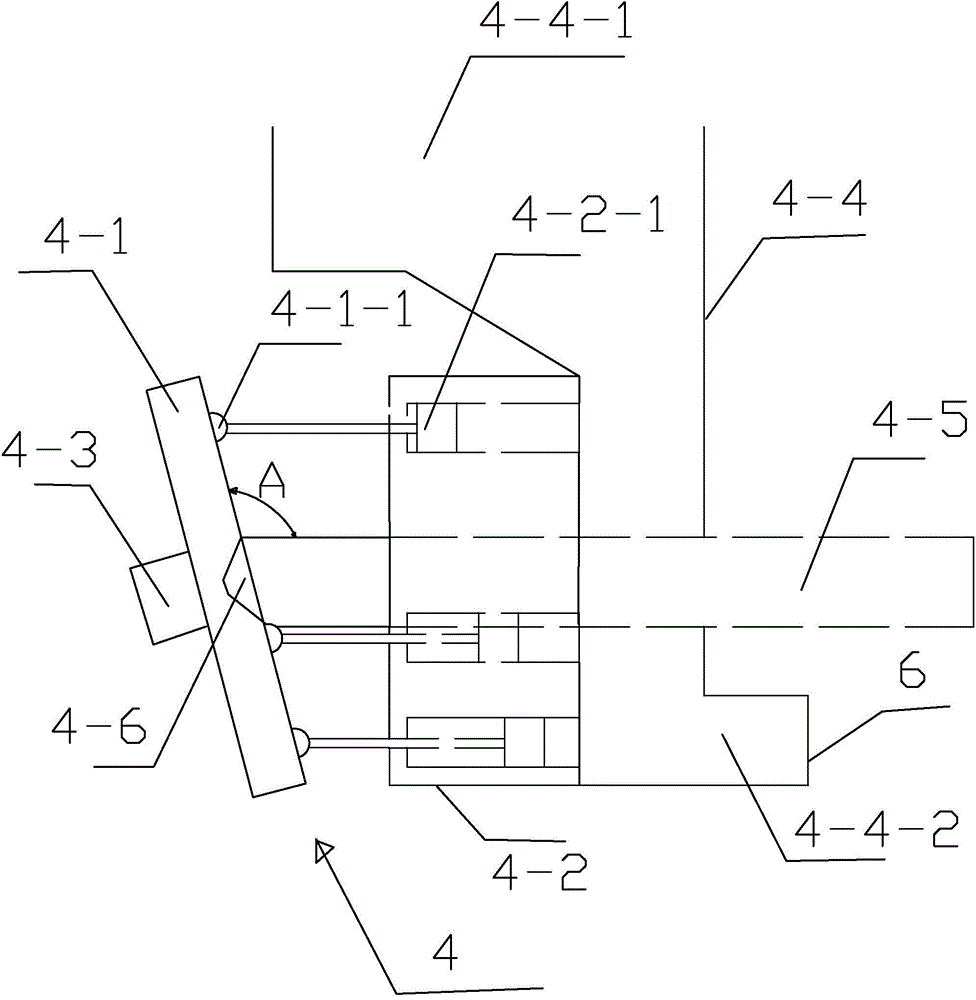

[0018] refer to figure 1 and figure 2 , the present embodiment, a swash plate type suction and discharge mortar spraying plastering machine, includes a support 1, a body 2 that moves up and down along the support 1, and the body 2 is provided with a wiper 3, a swash plate suction and discharge mortar device 4, and a reciprocating spray mortar The device 5 , the swash plate suction and discharge mortar device 4 and the reciprocating spray mortar device 5 are connected by a hose 6 .

[0019] Swash plate suction and discharge mortar device 4 includes swash plate 4-1, ring 4-2, thrust bearing 4-3, ash shaker 4-4, horizontal transmission shaft 4-5 and bevel gear device 4-6, swash plate 4 One end of -1 is installed on the body 2 through the thrust bearing 4-3, and the other end of the swash plate 4-1 meshes with the horizontal transmission shaft 4-5 through the bevel gear device 4-6 and forms an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com