Large pipe shed construction method by using Luoyang shovel

A construction method, Luoyang shovel technology, applied to drilling equipment and methods, drill pipes, casings, etc., can solve problems such as hole wall convergence deformation, construction progress impact, demolition, etc., to achieve reduced convergence deformation, easy deviation correction, The effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the technical innovation clearer, the implementation mode of the technical innovation will be further described in detail below in conjunction with the accompanying drawings.

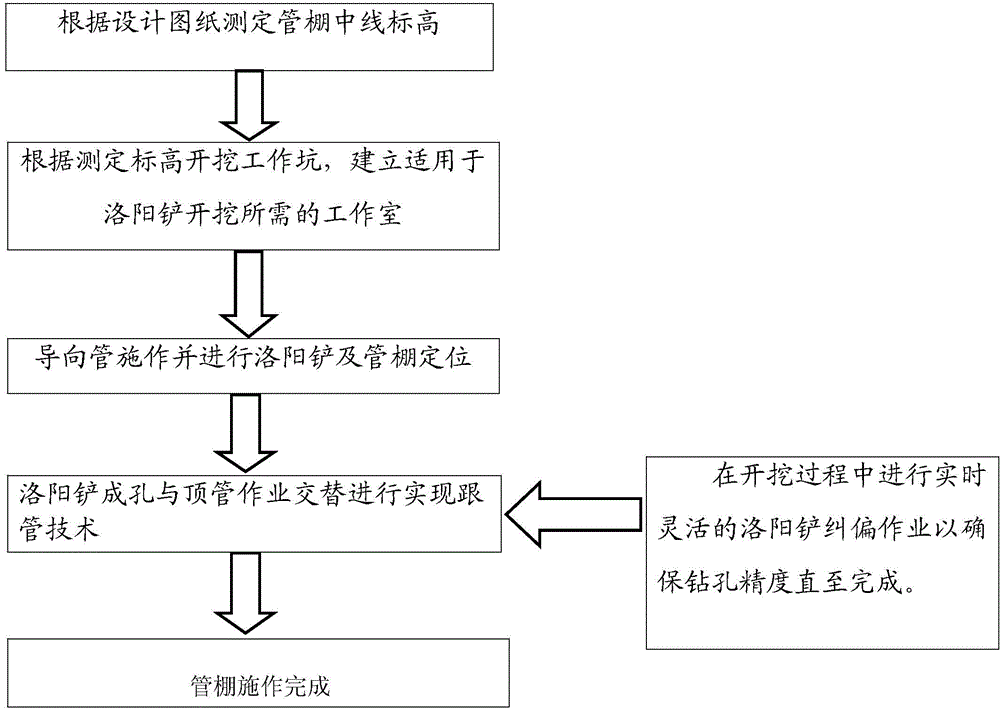

[0024] see figure 1 , a Luoyang shovel construction method for a large pipe shed, the specific construction process includes:

[0025] 1. Measure the elevation of the center line of the pipe shed according to the design drawings;

[0026] Specifically, this embodiment measures the centerline and elevation of the pipe shed in combination with the design drawings. In order to ensure the accuracy of the hole, the error of the hole should be controlled within ±0.1°. For structures with a length less than 50m, if the two ends of the entrance and exit are constructed at the same time, it needs to be closed through the measurement. The measurement accuracy complies with the current "Measurement Regulations". The pipe sheds are Ф108 sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com