Adjustable vibration isolator

A vibration isolator and adjustable technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of constant stiffness and damping of shock absorbers, equipment damage, and attenuation of vibration damping effects of shock absorbers And other problems, to achieve the effect of not easy material aging, high service life, and avoid equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

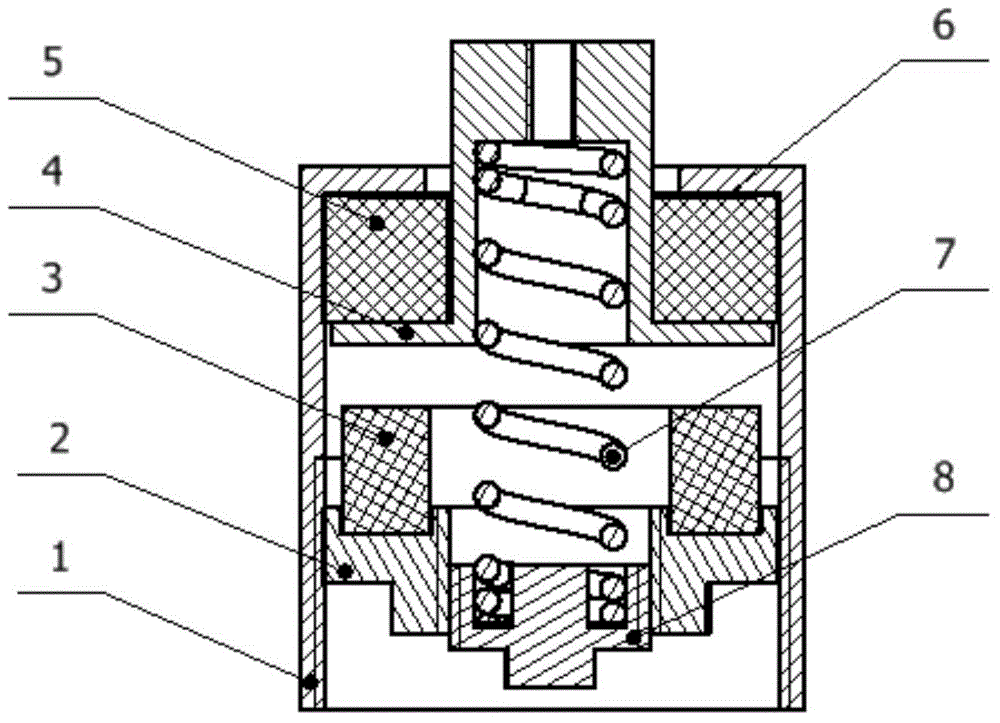

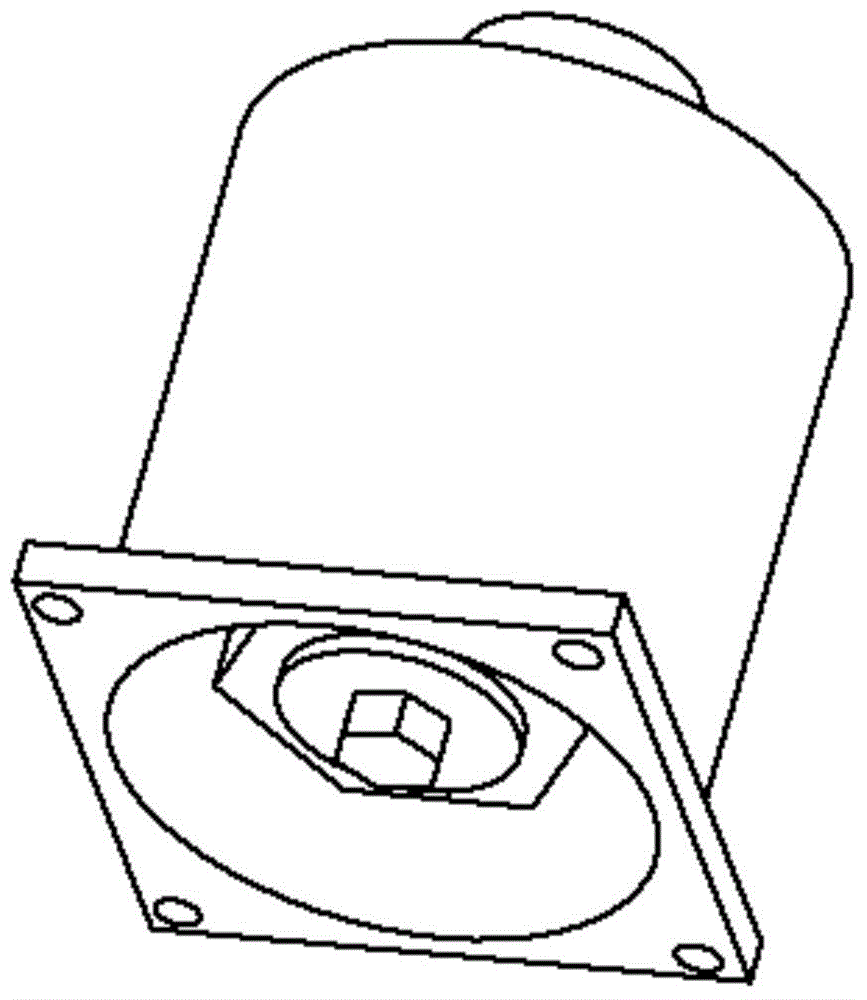

[0013] An adjustable vibration isolator of the present invention, such as figure 1 , 2 shown, including:

[0014] Including shell 1, damping adjustment knob 2, lower metal mesh pad 3, installation core 4, upper wire mesh pad 5, retainer 6, stiffness spring 7, stiffness adjustment knob 8;

[0015] The shell 1 is a cylindrical shell with an open bottom and a hole at the top. The lower part of the inner surface of the shell 1 is provided with an internal thread; the shell 1 is provided with a mounting core 4, which is a disc with a bottom. Cylinder, the top of the installation core 4 protrudes from the top opening of the housing 1, the center of the top of the installation core 4 has a screw hole for connecting with the equipment, and the lower part of the installation core 4 is provided with a cavity; the upper surface of the disk of the installation core 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com