Fluid control valve and application thereof

A technology for controlling valves and valves, applied in safety valves, balance valves, valve devices, etc., can solve problems such as inconvenient operation, outlet blockage, fluid volatilization, etc., and achieve the effects of being convenient to carry out, isolating air exchange, and preventing liquid volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific implementation cases described here are only used to explain the present invention, and are not intended to limit the present invention.

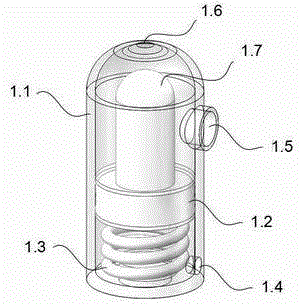

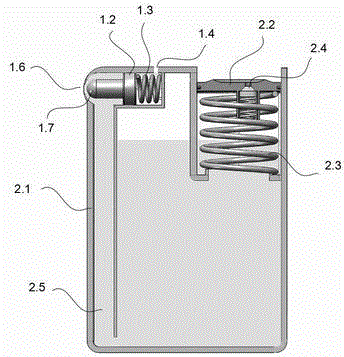

[0031] 1. The working principle of the valve body: figure 1 Shown: Under normal conditions, the valve body spring 1.3 is only affected by the elastic force of the spring, pushing the piston 1.2 and the spherical valve body 1.7 to close the valve body outlet 1.6. When the fluid enters the valve body cavity through the fluid inlet 1.5, as the pressure increases, The pressure of the fluid on the piston is also increasing. When the fluid pressure is greater than the spring force, the piston is pushed to open the spherical valve, and the fluid flows out through the outlet of the valve body. When the pressure conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com