Chloride conveying pipeline

A technology of feeding pipes and chlorides, which is applied in the field of chlorides, can solve the problems of greater human eye irritation, short pipe life, and serious pipe wear, and achieve extended regular maintenance time, good strength and wear resistance, and quantity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

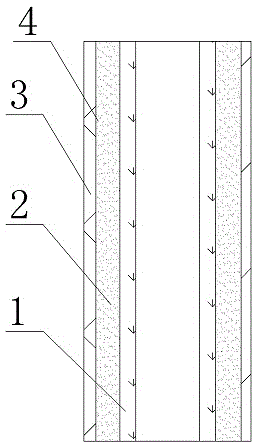

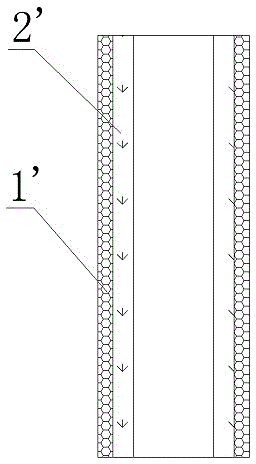

[0012] Such as figure 1 Shown, a kind of chloride feeding pipe, feeding pipe is followed by insulation layer 4, glass fiber reinforced plastics 1 from outside to inside, the present invention adopts the pipeline structure that wraps insulation layer outside glass fiber reinforced plastics 1, because glass fiber reinforced plastics has stronger plasticity, Moreover, its strength and wear resistance are better, which improves the wear resistance of the pipeline during pipeline maintenance. In addition, the invention adopts an insulating layer to reduce the heat loss of chlorides in the pipeline, thereby ensuring the protection of chlorides in the pipeline. No crystallization or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com