Structure-optimized compression-resistant wear-resistant polyurethane trundle and preparation method thereof

A technology of polyurethane and compounding method, which is applied in the direction of casters, wheels, transportation and packaging, etc., can solve the problems of inability to carry large weight, poor safety in use, simple structure, poor shock absorption effect, etc., achieve strong plasticity, prolong service life, Good wear resistance and strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing polyurethane according to the invention. The percentages of components contained in the polyurethane are 10-20% of low molecular weight polyether; 20-30% of toluene diisocyanate; 10-20% of trimethylol propane; and dimethylformamide Solvent 3-6%; phosphoric acid 5-6%; tertiary amine catalyst 1-3%; organic acid 1-3%; isocyanate 1-2%; active hydrogen 1-2% and organic silicon 3-5%.

[0030] Further, the percentage content of the components contained in the polyurethane is 15% of low molecular weight polyether; 20% of toluene diisocyanate; 15% of trimethylolpropane; 20% of dimethylformamide solvent; 20% of phosphoric acid; tertiary amine catalyst 2%; organic acid 2%; isocyanate 1.5%; active hydrogen 1.5% and silicone 3%.

[0031] Further, the preparation method of low-molecular-weight polyether and toluene diisocyanate is as follows: pour low-molecular-weight polyether into a three-necked flask, stir evenly, dehydrate in vacuum for 4 hours, and then sl...

Embodiment 2

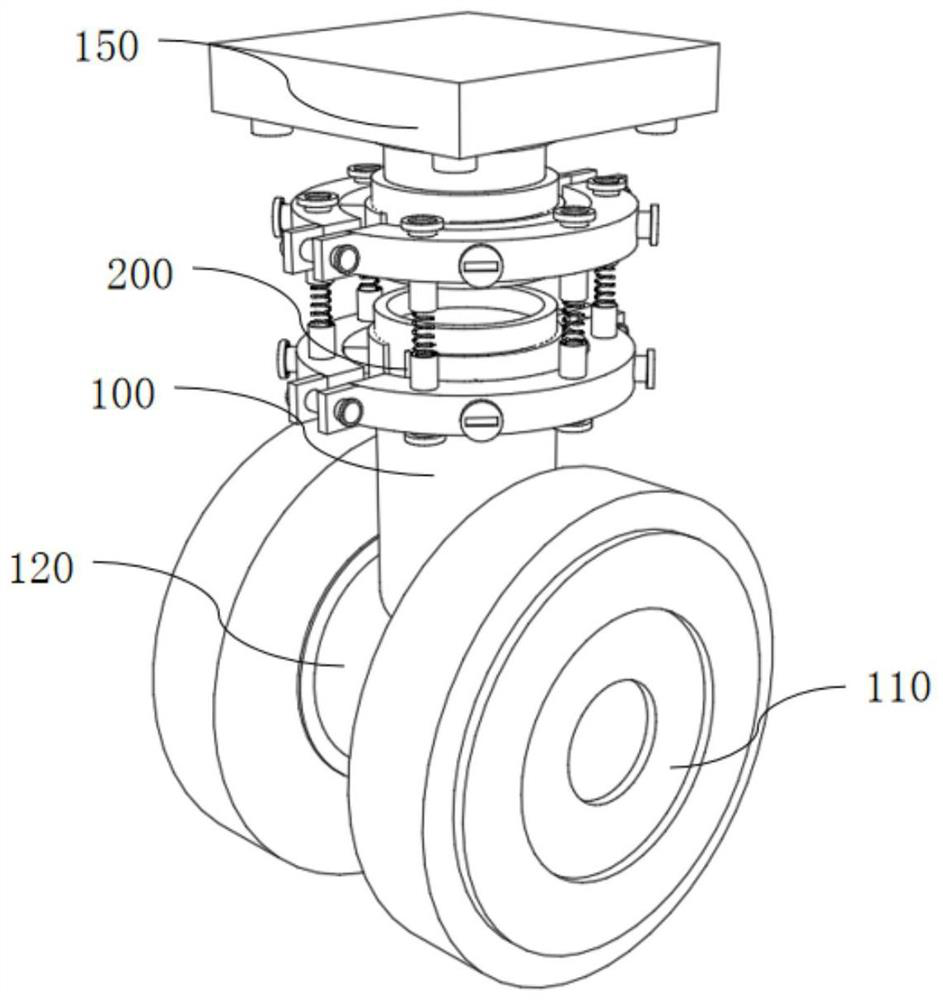

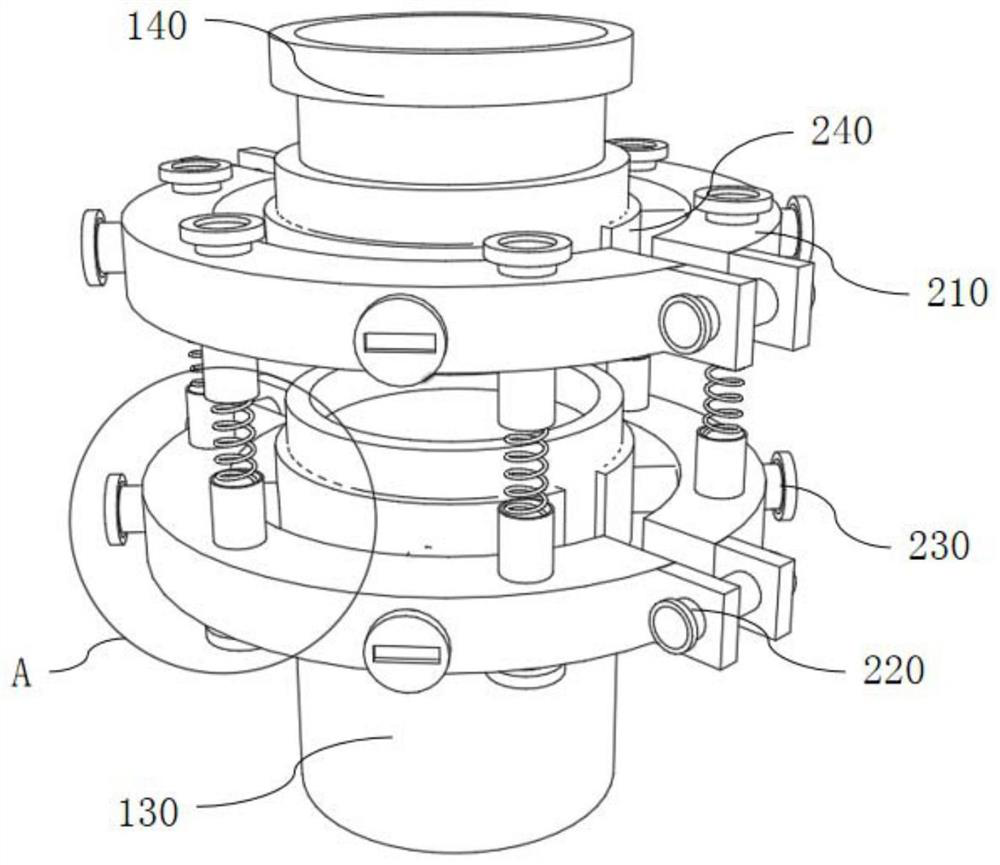

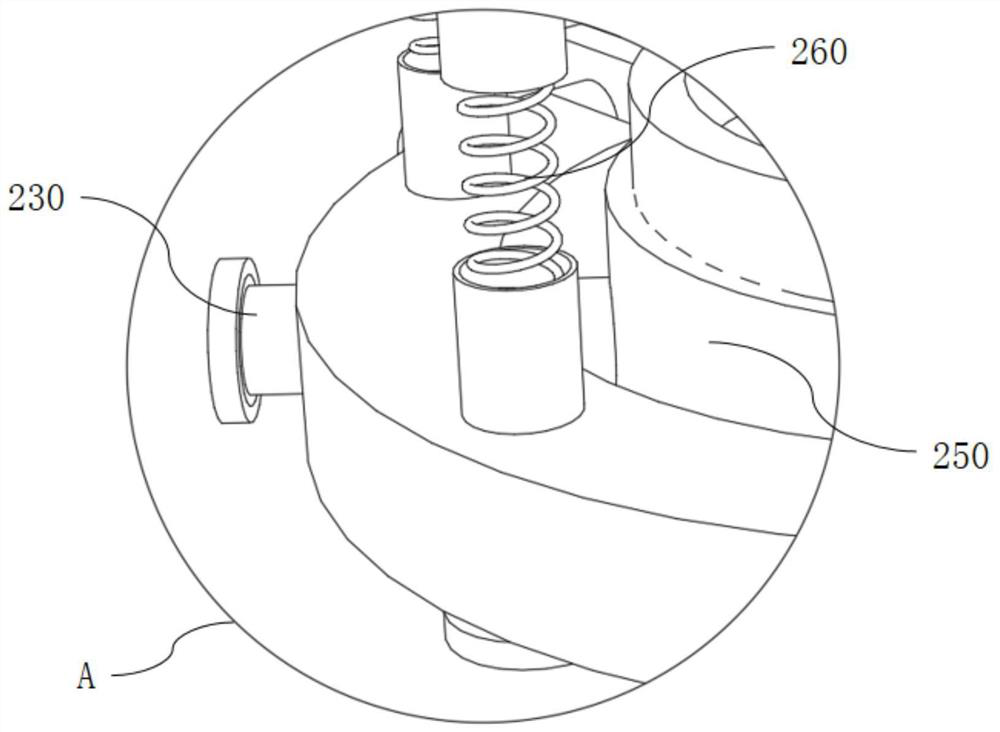

[0038] see Figure 1-3As shown, a structurally optimized anti-compression and wear-resistant polyurethane caster includes a wheel body 100 and a connecting shock absorbing device 200. The wheel body 100 includes a fixed column 130 and a cardan shaft 140. The connecting shock absorbing device 200 includes a first push plate 240 and For the second push plate 250 , one side surfaces of the two first push plates 240 are connected to the outer surface of the cardan shaft 140 , and one side surfaces of the two second push plates 240 are connected to the outer surface of the fixed column 130 .

[0039] Further, the wheel body 100 also includes a wheel 110, a rotating shaft 120 and a connecting plate 150, the two wheels 110 are rotatably matched with the rotating shaft 120, one end of the fixing column 130 is welded to the outer surface of the rotating shaft 120, and the lower surface of the connecting plate 150 is connected to the outer surface of the rotating shaft 120. Connected to...

Embodiment 3

[0042] Aiming at the abrasion resistance effect and compression resistance effect of the polyurethane of the present invention, the polyurethane of the present invention is selected. Preferably, the percentages of the components contained in it are respectively 15% of low molecular weight polyether; 20% of toluene diisocyanate; 15% of trimethylolpropane; 20% of dimethylformamide solvent; 20% of phosphoric acid; 2% of tertiary amine catalyst; 2% of organic acid; 1.5% of isocyanate; It has better wear resistance and compression resistance, and has a stronger bearing capacity. At the same time, connecting the shock absorbing device 200 in a structurally optimized compressive and wear-resistant polyurethane caster of the present invention changes the original shock absorbing structure, and uses splints 210 to The parts of the wheel main body 100 are connected, and fastening rods 230 are used to fasten the clamping parts, so that the connection of each part is more stable, the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com