Dual-seal socket and spigot type flexible connection structure for large-diameter spiral welded steel pipes

A technology for flexible connection and welding of steel pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe elements, expansion compensation devices for pipelines, etc., and can solve problems such as labor-consuming, time-consuming, high cost, and heavy welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

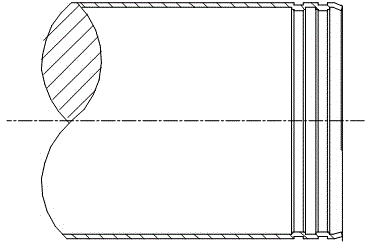

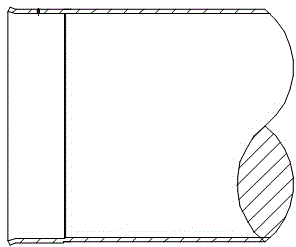

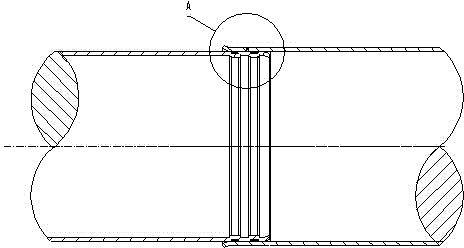

[0014] Such as Figure 1-Figure 4 As shown, the large-diameter spiral welded steel pipe double-seal socket flexible connection structure, the two spiral welded steel pipes connected to each other include the spiral welded intubation tube 1 and the spiral welded intubation tube 2, and the connection end of the spiral welded intubation tube 1 is opened with a groove machine. Two parallel annular grooves; the connecting end of the spiral welded pipe 2 is formed by expanding the diameter of the diameter expansion die; two special-shaped sealing rings 3 are put into the two annular grooves, and the outer diameter of the two special-shaped sealing rings 3 after installation If it is larger than the outer diameter of the spiral welding cannula, use a special tool or tooling to insert and connect the spiral welding cannula 1 and the spiral welding receiving pipe 2 .

[0015] The outer diameter of the spiral welded intubation tube 1 and the spiral welded support tube 2 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com