Blow molding LED (light emitting diode) grille lamp

A technology of LED grille lights and light panels, applied in lighting devices, light sources, fixed lighting devices, etc., can solve the problems of high production, installation and maintenance costs, unfavorable ceiling hoisting, cumbersome installation and disassembly, etc., to simplify the assembly process, improve the Production and assembly efficiency, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

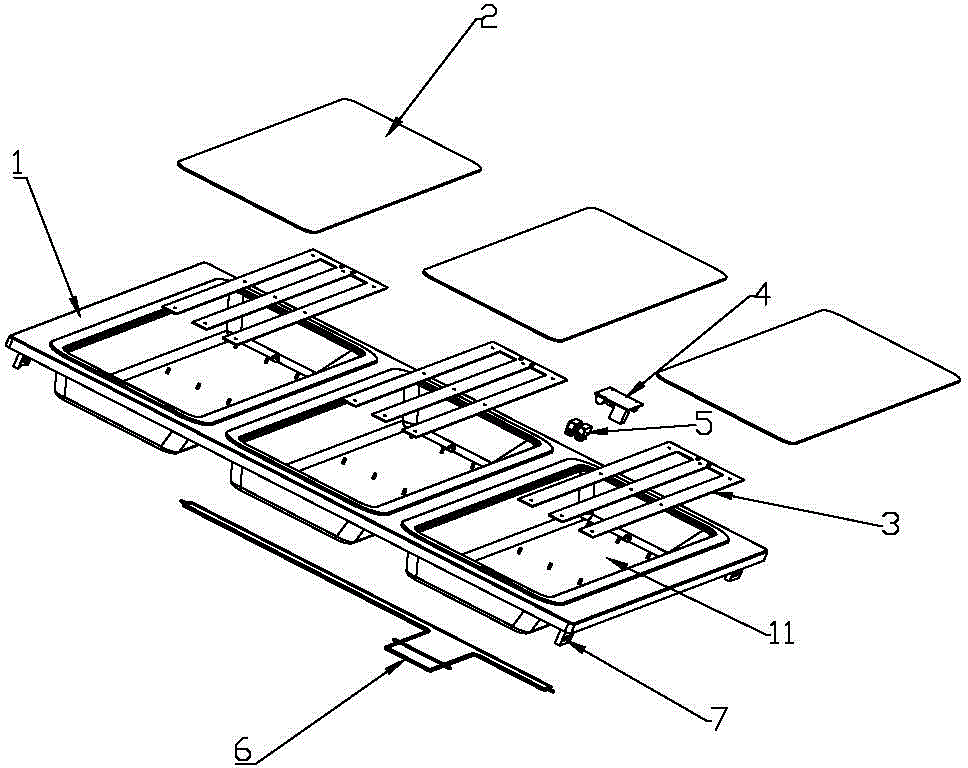

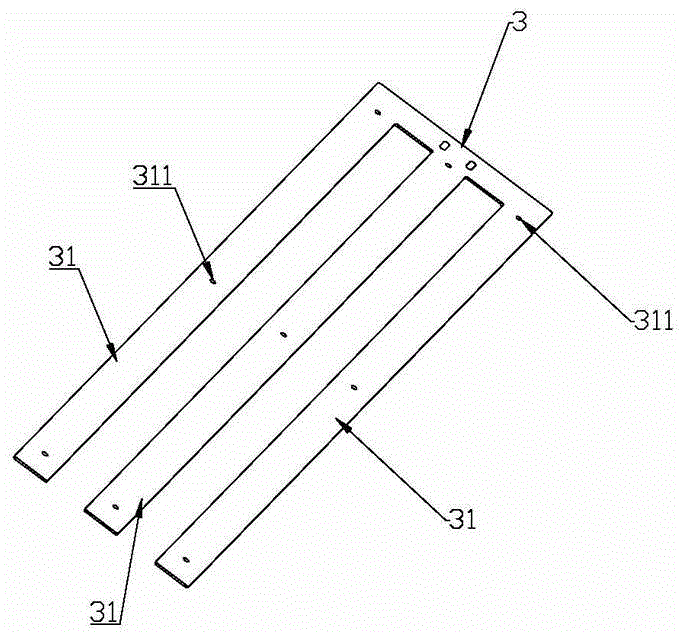

[0039] A kind of blow molding LED grid lamp of the present invention, as Figure 1 to Figure 5 As shown, it includes a lampshade 2, a lamp panel 1 and a power supply assembly. The lamp panel 1 is a lamp panel 1 integrally formed by high-density polyethylene material through a blow molding process. The lamp panel 1 is formed with a plurality of accommodation slots 11, each of which accommodates A group of lamp boards 3 are arranged in the groove 11 . Compared with the metal stamping process in the prior art, the lamp panel 1 of the present invention is integrally formed by high-density polyethylene material through a blow molding process, and this process can be made into a thinner lamp panel 1. The vinyl material itself has light weight and good insulation performance. Under the condition of the same strength, it can greatly reduce the weight of the entire LED lamp, reduce the load-bearing pressure on the ceiling, and be more convenient to hoist on the ceiling. And the blow mo...

Embodiment 2

[0061] The main technical scheme of this embodiment is exactly the same as that of embodiment 1, the difference is:

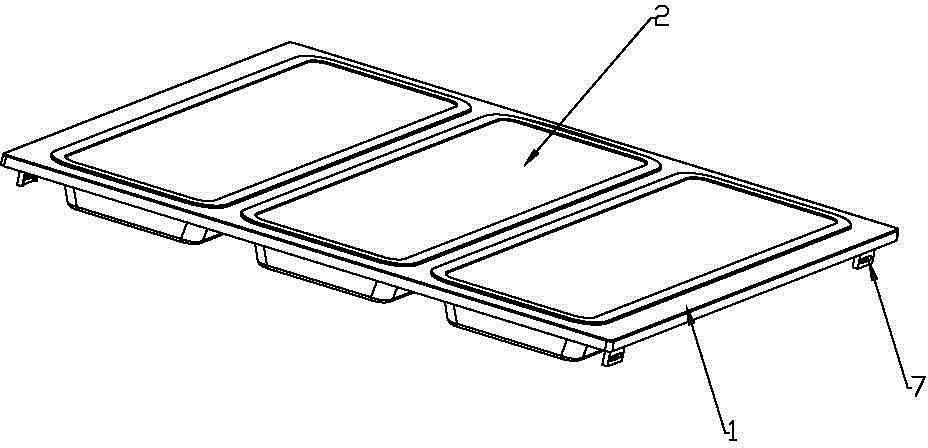

[0062] like Figure 5 and Figure 6 As shown, the lamp panel 1 is a lamp panel 1 with a hollow cavity formed by high-density polyethylene material through a blow molding process. Since the lamp panel 1 is a hollow structure, the weight of the lamp panel 1 is further reduced, making the entire LED lamp more compact. light.

[0063] In order to strengthen the strength of the hollow structure of the lamp panel 1, in this embodiment, several reinforcing grooves 15 are integrally formed on the back of the accommodating groove 11, and the parts provided with the reinforcing grooves 15 make the hollow layers be pressed together to play a role. The function of the reinforcing ribs improves the installation stability of the lamp panel 3 .

[0064] At the same time, several reinforcing grooves 15 are also provided on the peripheral edge of the back of the lamp panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com