Multi-time horizontal movement staggered spiral industrial CT scanning imaging method

A technology of CT scanning and imaging methods, applied in the field of CT scanning, can solve the problems of limited life and low detection efficiency, and achieve the effects of reducing hardware costs, high reconstruction quality, and reducing CT detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

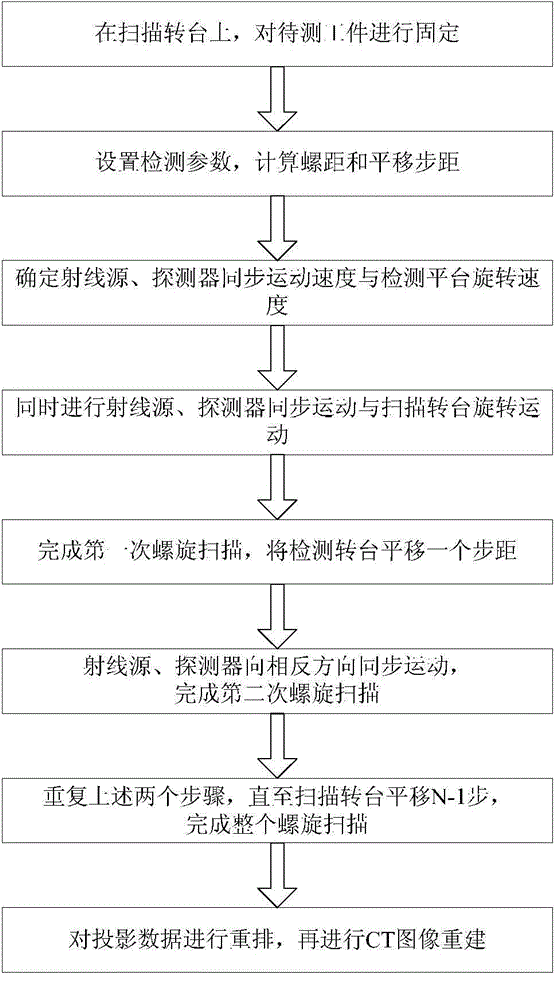

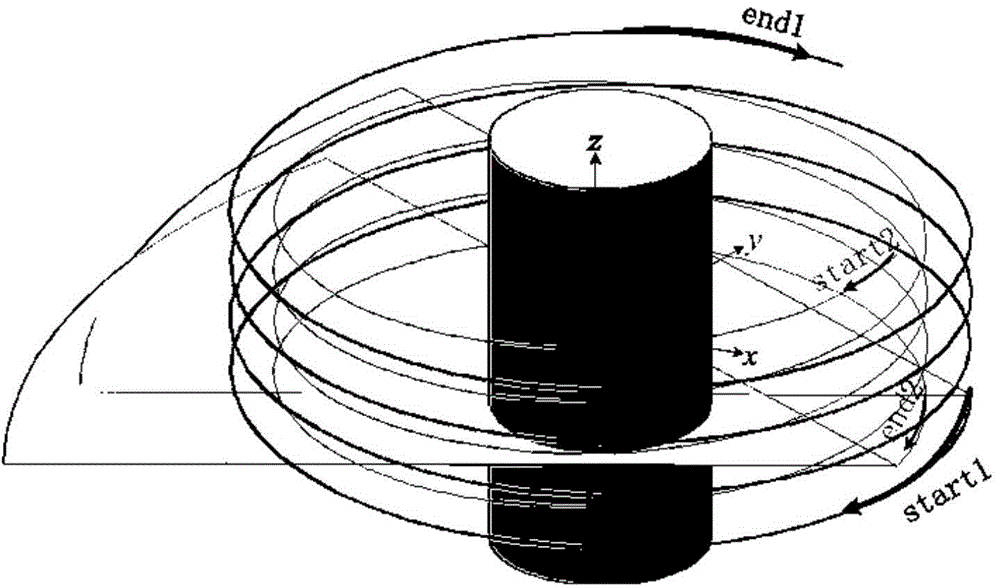

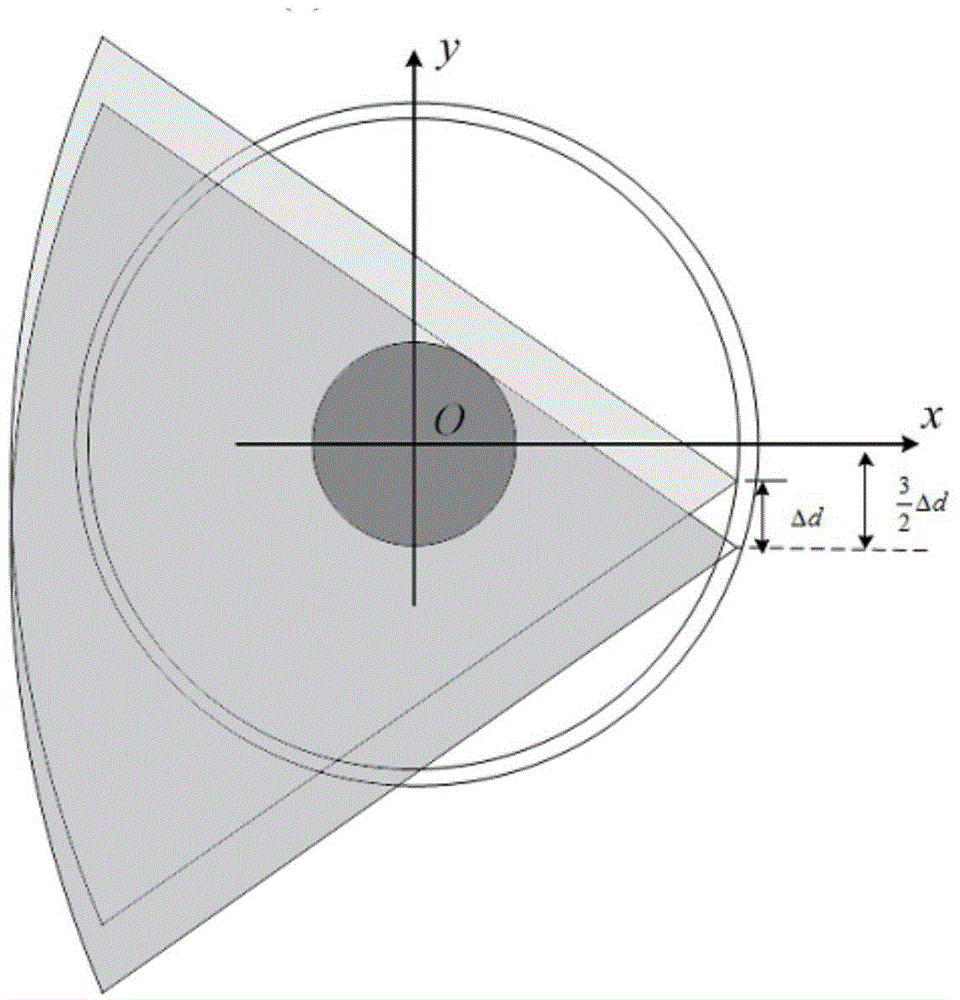

[0027] A kind of multi-translation interlaced helical industrial CT scanning imaging method provided by the present invention, the flow process of this method is as follows figure 1 shown. Since the clockwise rotation of the object around the turntable is equivalent to the counterclockwise rotation of the ray source and detector around the turntable, similarly, the counterclockwise rotation of the object around the turntable is equivalent to the clockwise rotation of the ray source and detector around the turntable. For the convenience of description, the following All the descriptions assume that the object is fixed, the ray source and detector rotate around the turntable, and the ray source and detector are also assumed to translate along the axis of the turntable. The following description uses four translations of the turntable to illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com