Novel railway signal relay contact system

A railway signal and contact system technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., to achieve the effects of easy installation, simple structure, and improved sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

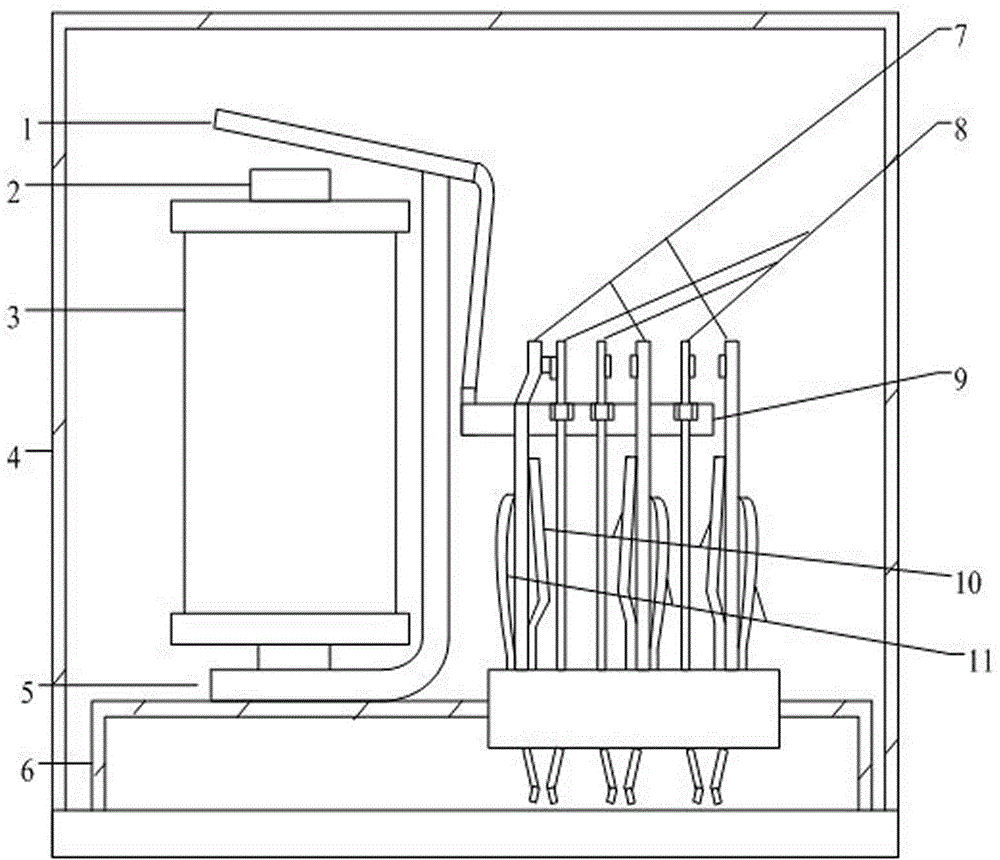

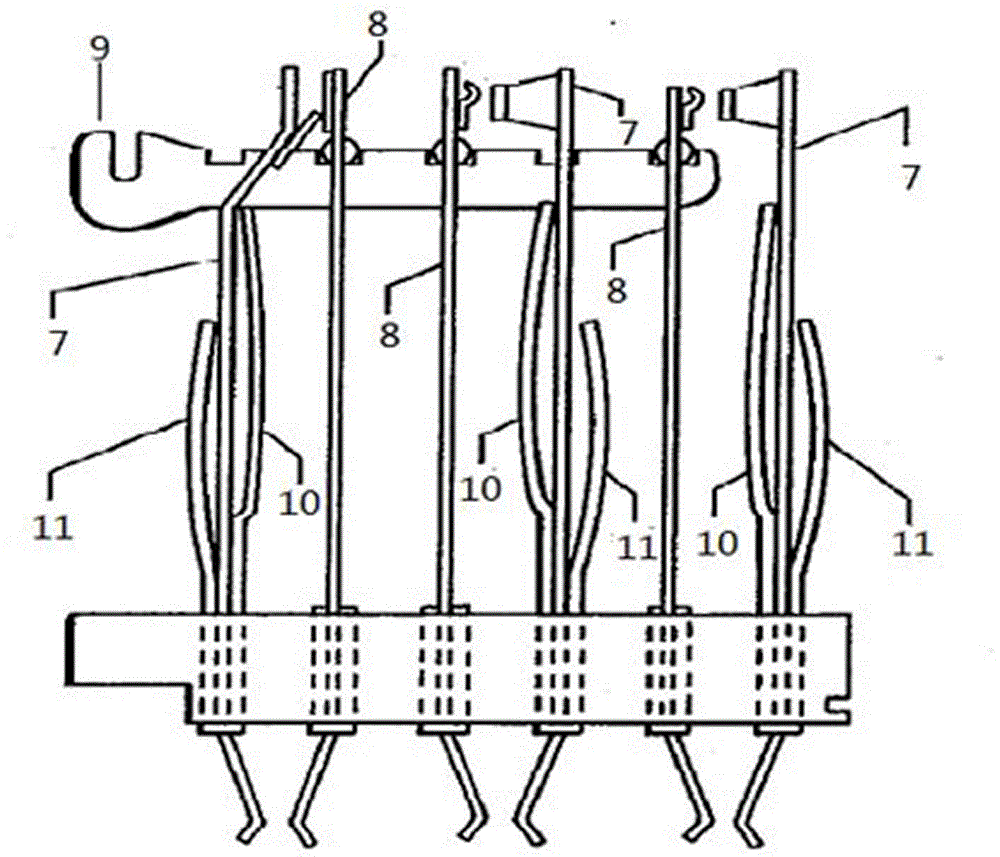

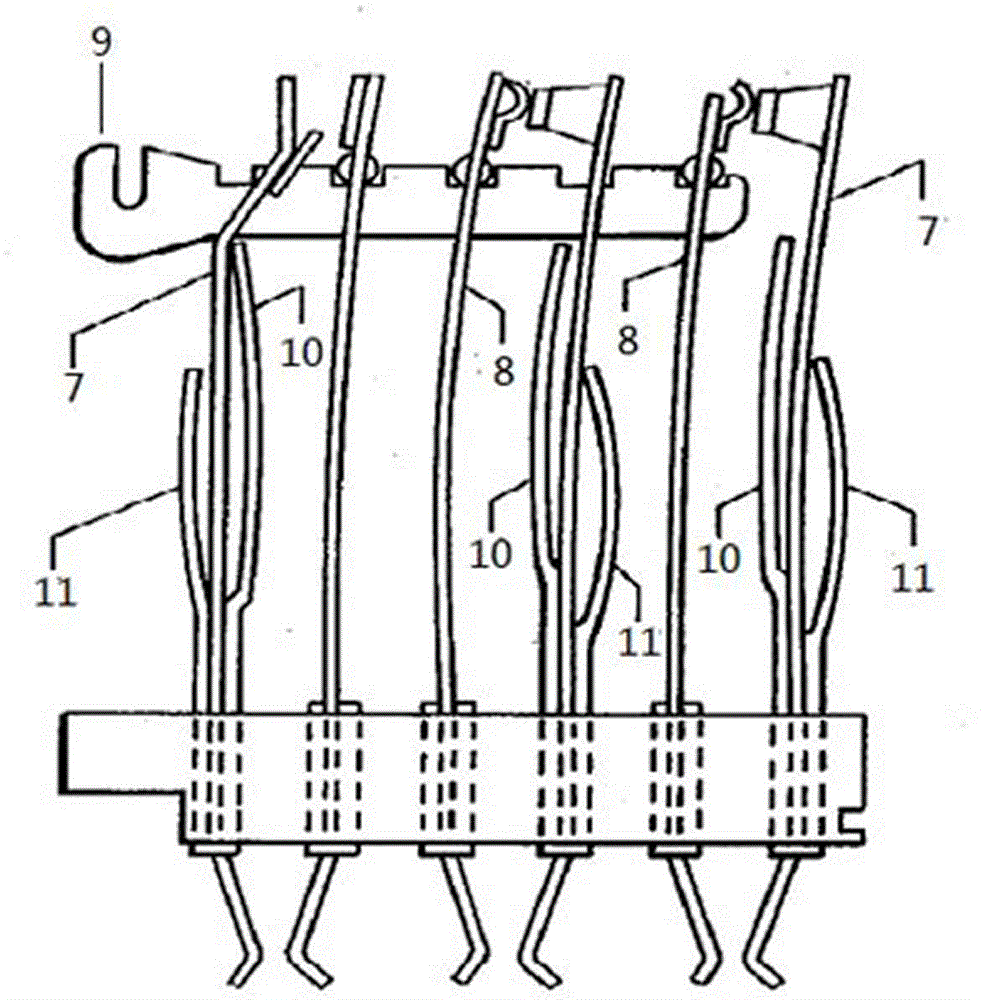

[0022] refer to Figure 1 ~ Figure 3 , this new railway signal relay contact system is a C-type elastic DC relay, the coil 3 is wound on the core column 2, and the yoke 5 is installed on the base 6. The armature 1 is connected to the insulating pull rod 9 . The moving reed 8 and the static reed 9 are pressed into the base, the static contact is divided into a front contact and a rear contact, the insulating pull rod connects the moving reed 8 and the armature 1, and the insulating pull rod 9 connects with the moving reed 8 through the groove set on the top. Pull out together, rigid stop sheet 10 and elastic pressure sheet 9 are installed on static spring sheet 7 both sides, and the bottom end is pressed in the base.

[0023] After the armature moves, the static reed 7 with the front contact is disconnected from the moving contact under the obstruction of the rigid stopper 10; The moving contacts are tightly combined.

[0024] Working process of the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com