Three-phase motor driving control device

A technology of three-phase motors and turbomolecular pumps, applied in AC motor control, emergency protection circuit devices, measuring devices, etc., can solve problems such as waste of time, time required, and decrease in vacuum degree, so as to improve versatility and increase costs The effect of suppressing and suppressing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

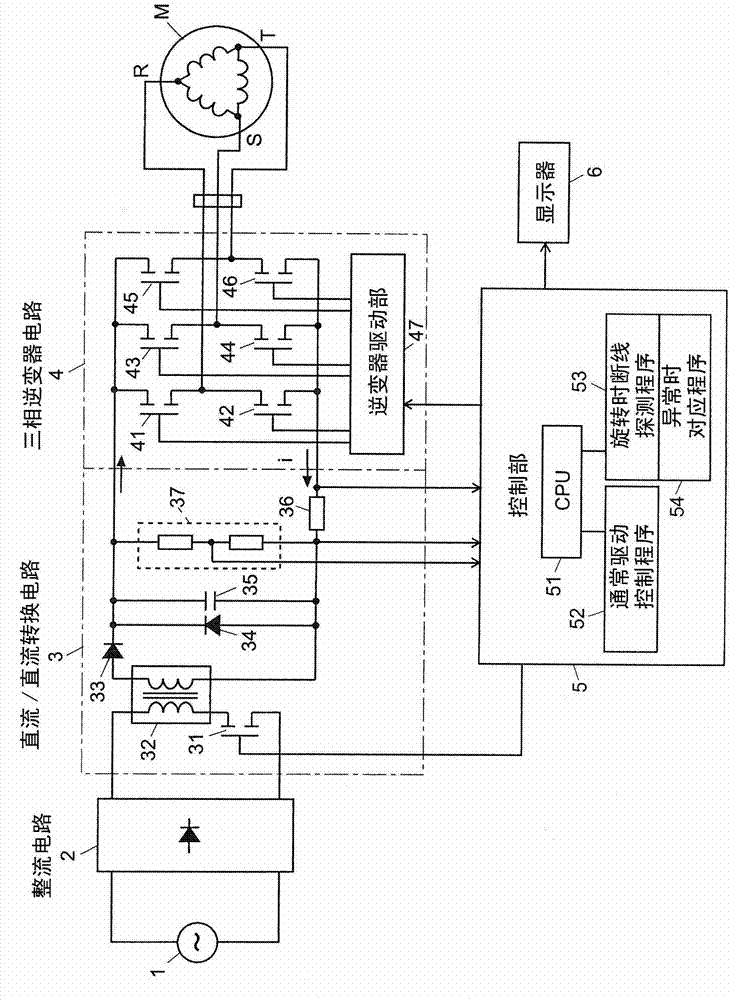

[0028] Below, refer to Figure 1 ~ Figure 3 , a three-phase motor drive control device according to an embodiment of the present invention will be described. figure 1 It is a block configuration diagram of main parts of the three-phase motor drive control device of this embodiment.

[0029] As a general structure of the three-phase motor drive control device of this embodiment, the AC power supplied from a single-phase 200V (or 100V) commercial AC power supply 1 is converted into DC power by a rectifier circuit 2, and further in a DC / DC conversion circuit 3 DC power converted to a specified voltage. Then, the DC power is converted into AC power supplied to the R, S, and T phases of the three-phase motor M by the three-phase inverter circuit 4 .

[0030] More specifically, the rectifier circuit 2 includes a diode bridge circuit not shown, an electrolytic capacitor for smoothing, and the like, and outputs a predetermined DC voltage. In the DC / DC conversion circuit 3, the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com