Reflection type artificial crystal optical aberration hartmann measuring apparatus

An intraocular lens, reflective technology, applied in the direction of prosthesis, testing optical performance, medical science, etc., can solve the problem that the measurement of intraocular lens aberration is still blank, and achieve the effect of simple structure, reliable detection and good instrument versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

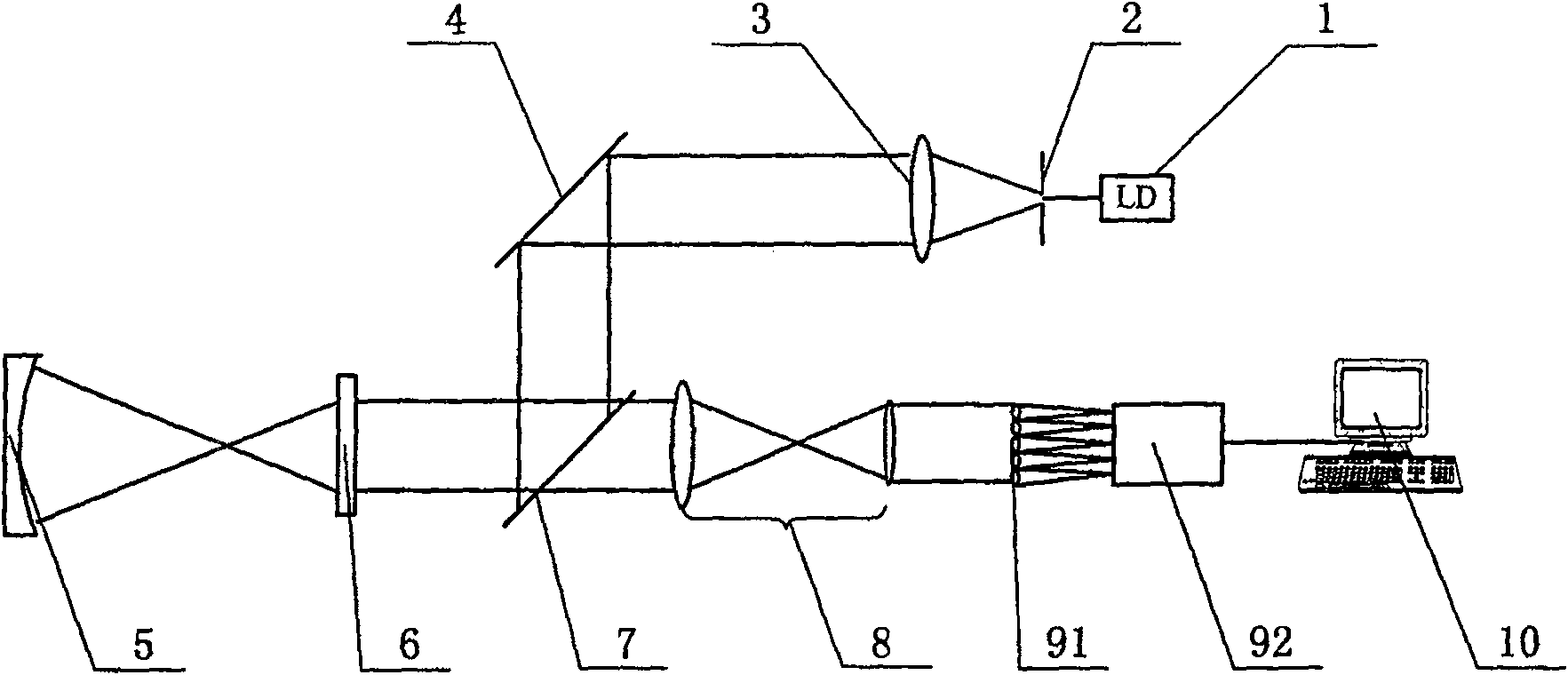

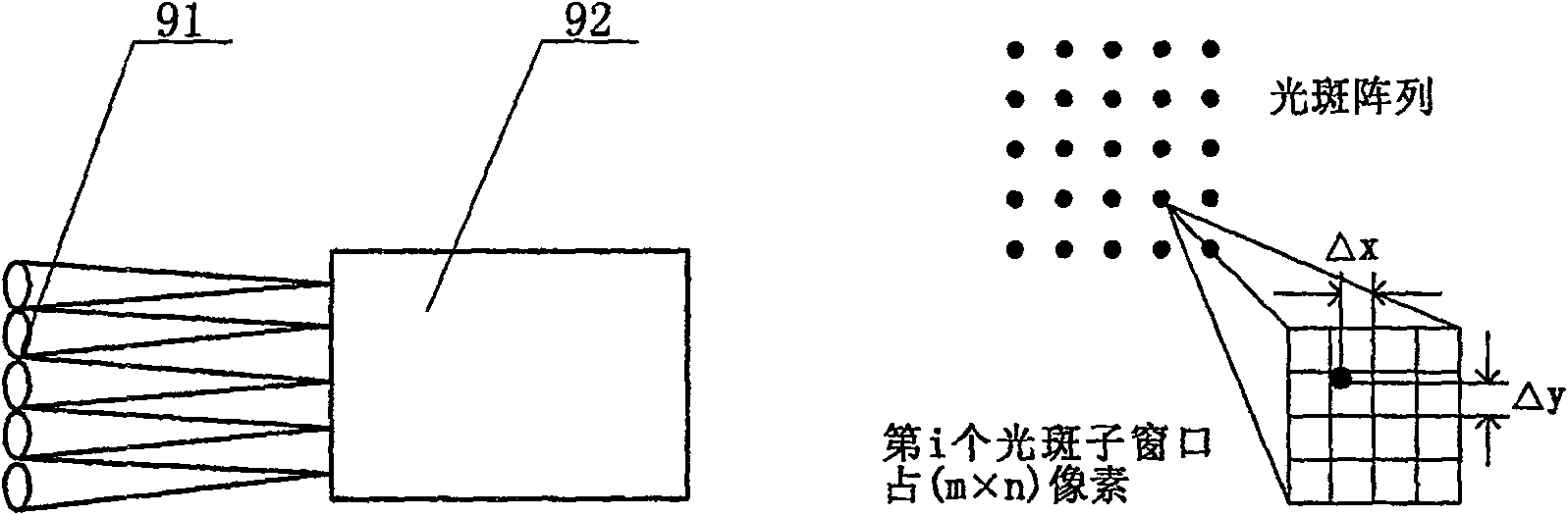

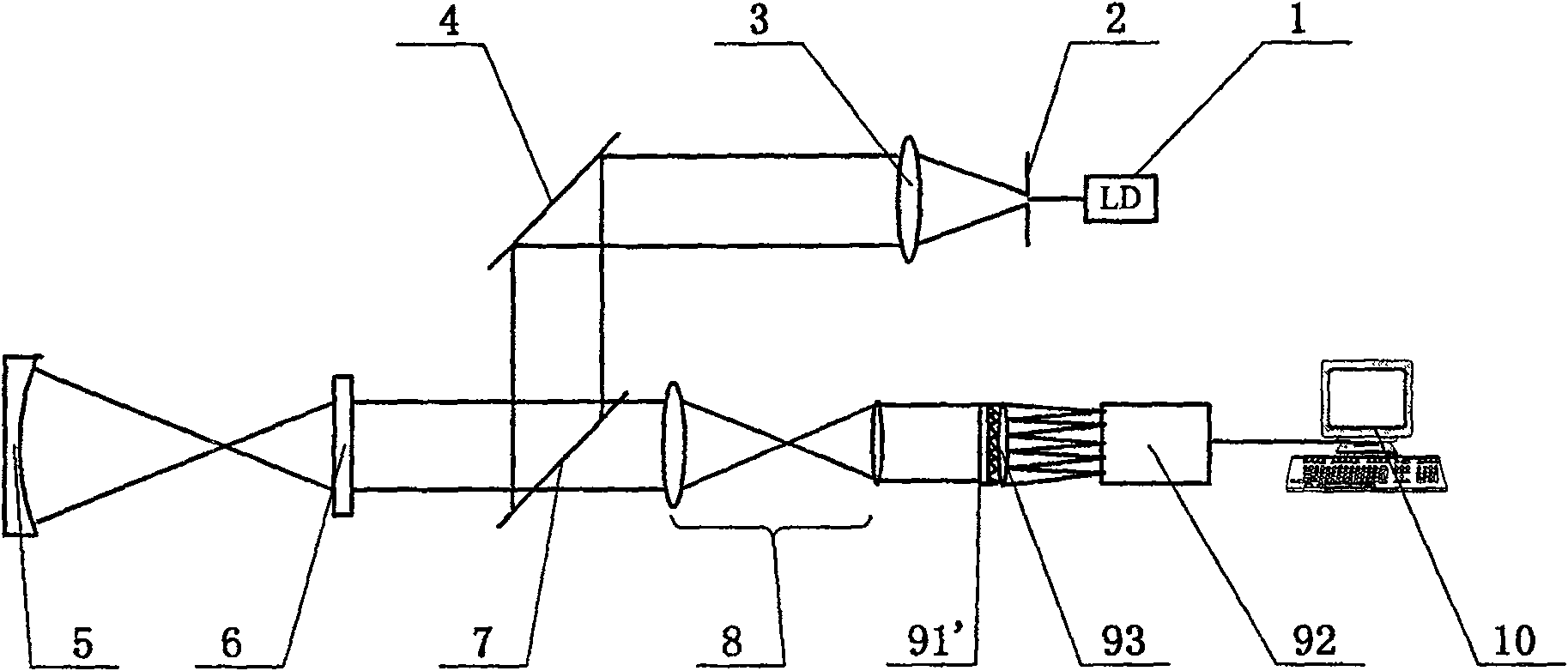

[0019] Such as figure 1 As shown, it is a principle diagram of intraocular lens aberration measurement in which the aperture division element is a microlens array in the present invention, and it includes a light source 1, a beam filtering system, a beam matching system 8, a standard spherical reflector 5, and an aperture division element, namely micro Lens array 91, photodetector 92 and computer 10, wherein the aperture division element 91 and photodetector 92 constitute a Hartmann wavefront sensor, the beam filtering system is composed of pinhole 2 and collimating mirror 3, and the beam matching system 8 is composed of two A beam of light composed of lenses or mirrors of different focal lengths matches the telescope. The light emitted by the light source 1 is filtered by the pinhole 2, collimated by the collimator 3 to be parallel light exiting, passes through the artificial lens 6 to be tested through the reflector 4 and the beam splitter 7, and the transmitted light wave r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com