Fixed rate EGR system

A LP-EGR, HP-EGR technology, applied in charging system, electrical control, machine/engine, etc., can solve problems such as long conveying delay, improve durability, improve EGR mixing, reduce system cost and complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

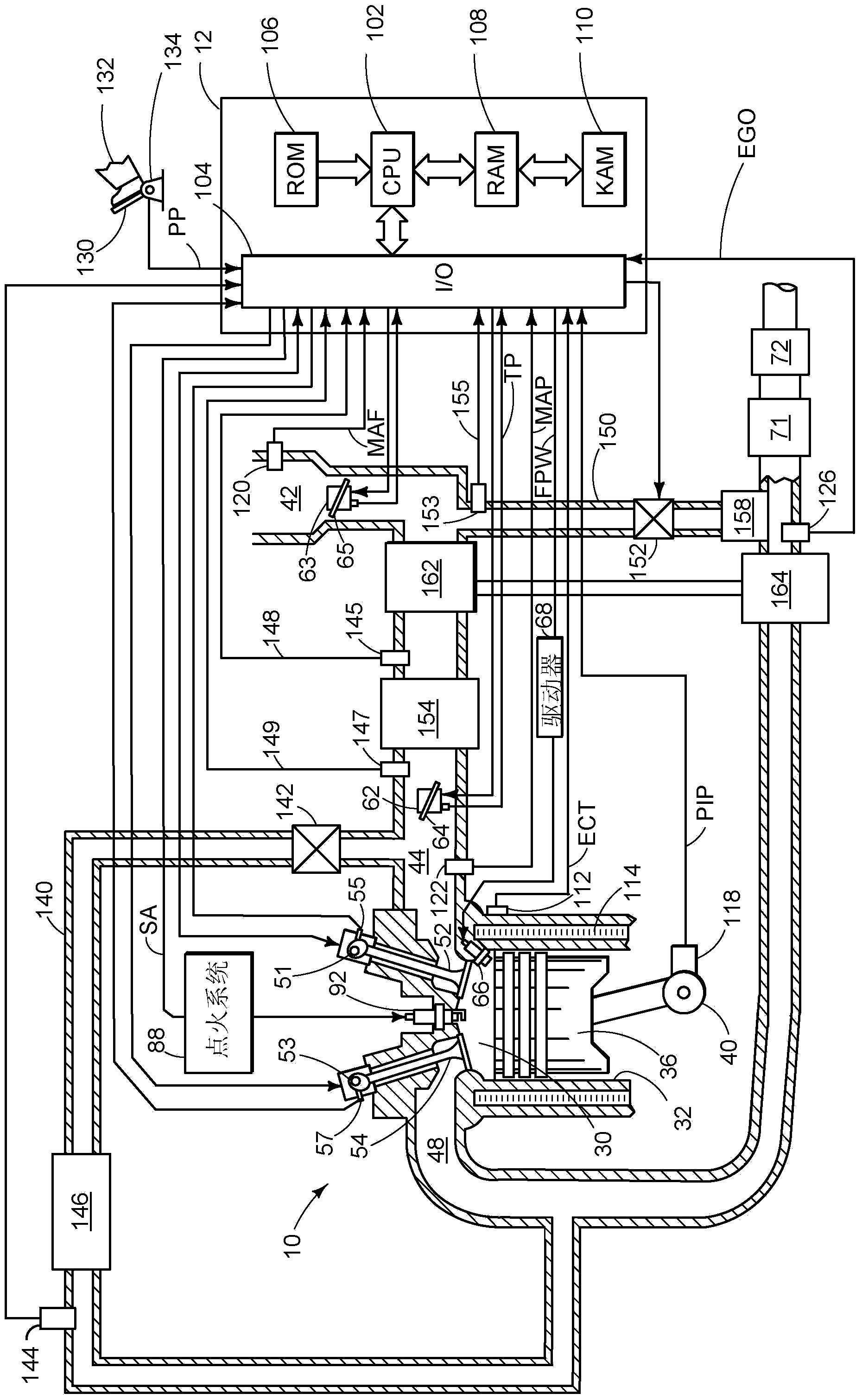

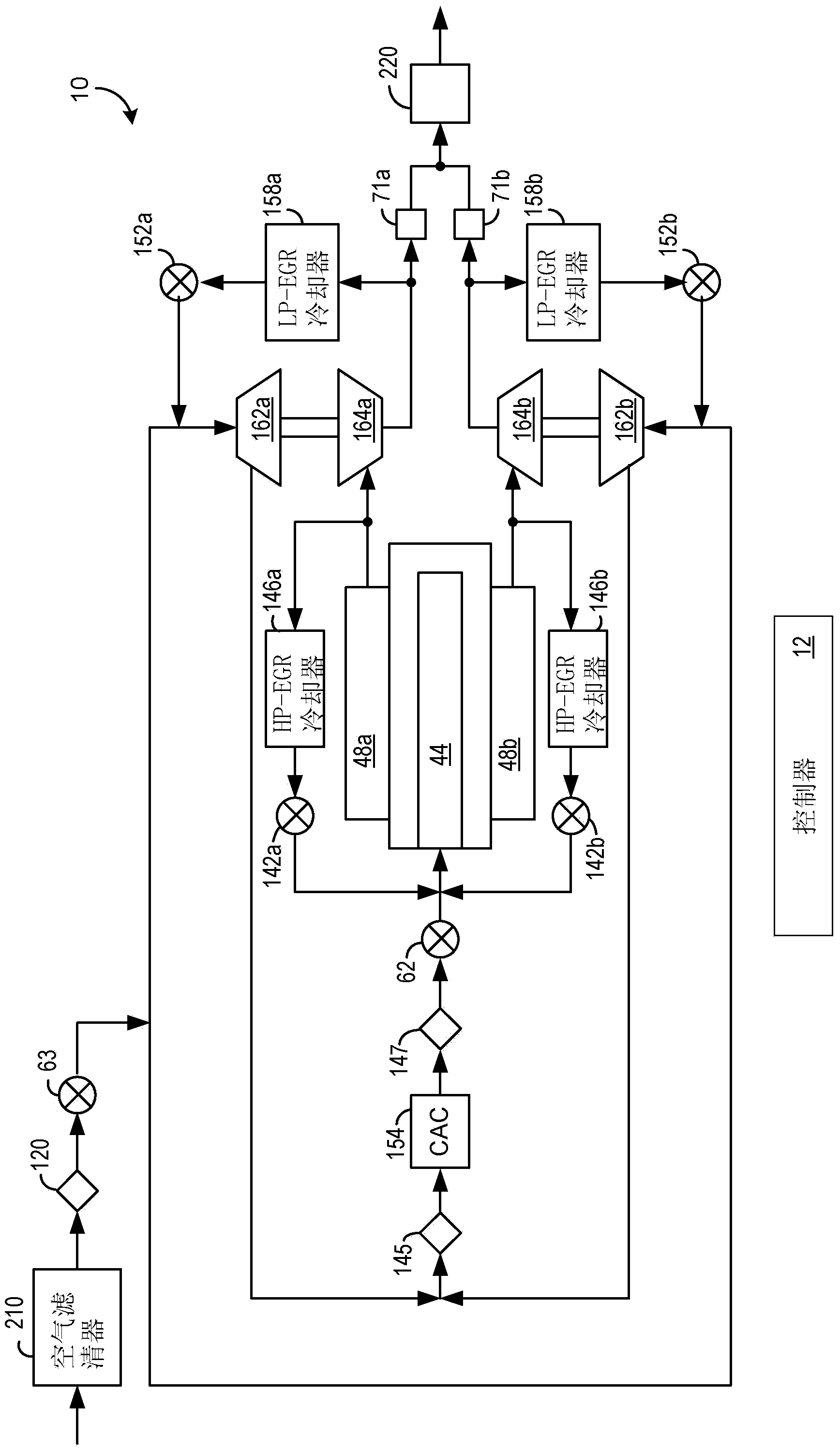

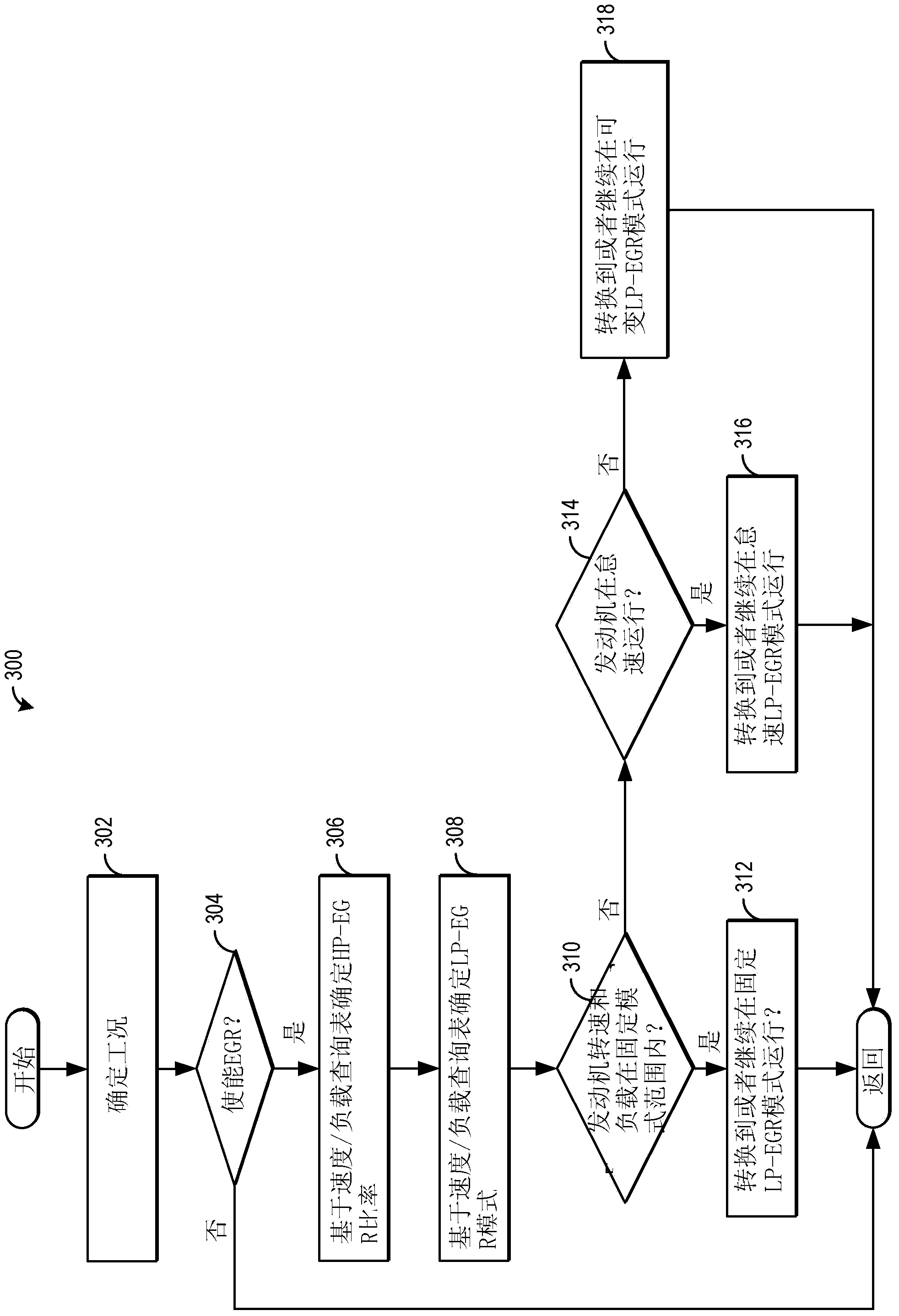

[0016] This specification relates to an EGR system coupled to a turbocharged engine in a motor vehicle. In a non-limiting example, an engine can be configured as figure 1 A portion of the system described wherein the engine includes at least one cylinder, a control system, a turbocharger and an exhaust gas recirculation system, among other features. The engine can be configured with figure 2 Multiple cylinder banks as described in . figure 1 and figure 2 The system can be used for example Figure 3-6 The example method operation described in . Various EGR operating modes can be mapped by engine speed-load (such as in Figure 7 the one depicted in) OK. Figure 8A and Figure 8B description in Figure 3-Figure 6 Various engine operating parameters during execution of the method.

[0017] now refer to figure 1 , which shows a schematic diagram of one cylinder of a multi-cylinder engine 10 that may be included in the propulsion system of the illustrated automobile. En...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com