A topology structure of an intensive direct current ice-melting device

A technology of DC ice melting and topological structure, which is applied in the direction of circuit devices, harmonic reduction devices, overhead installations, etc., can solve the problems of heavy operation and maintenance workload, low utilization rate of ice melting devices, and low operation reliability, and achieve simplification The device topology design, the realization of device function expansion, and the effect of improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

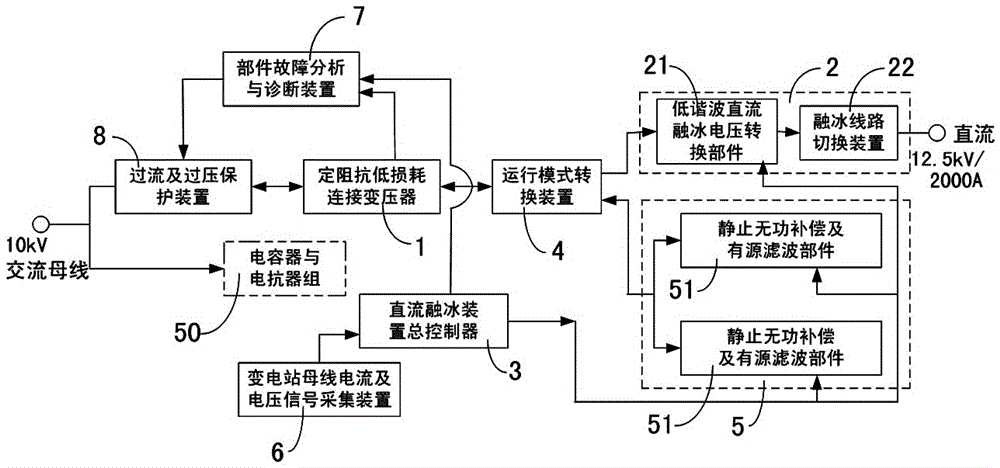

[0019] figure 1 Shown is an embodiment of the topology of the intensive DC ice-melting device integrating reactive power compensation and active filtering in the present invention, which can realize 12.5kV DC voltage output, and its DC ice-melting capacity is 25MW, and the static reactive power compensation capacity It is ±15Mvar, and can actively filter the 13th and below low-order harmonics. will be combined below figure 1 The present invention will be described in detail with reference to the illustrated embodiments.

[0020] Such as figure 1 As shown, the topological structure of the intensive DC ice-melting device in this embodiment includes a constant-impedance low-loss connection transformer 1, an ice-melting branch 2 and a general controller 3 of the DC ice-melting device. The control terminal of the ice-melting branch 2 is connected to the DC melting The main controller 3 of the ice plant is connected, and the topology structure also includes an operation mode conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com