Safety oscillation damping vibrating screen

A vibrating sieve, safe technology, applied in the direction of vibrating fluid, filter screen, solid separation, etc., can solve the problems of low production efficiency, reduce vibration intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

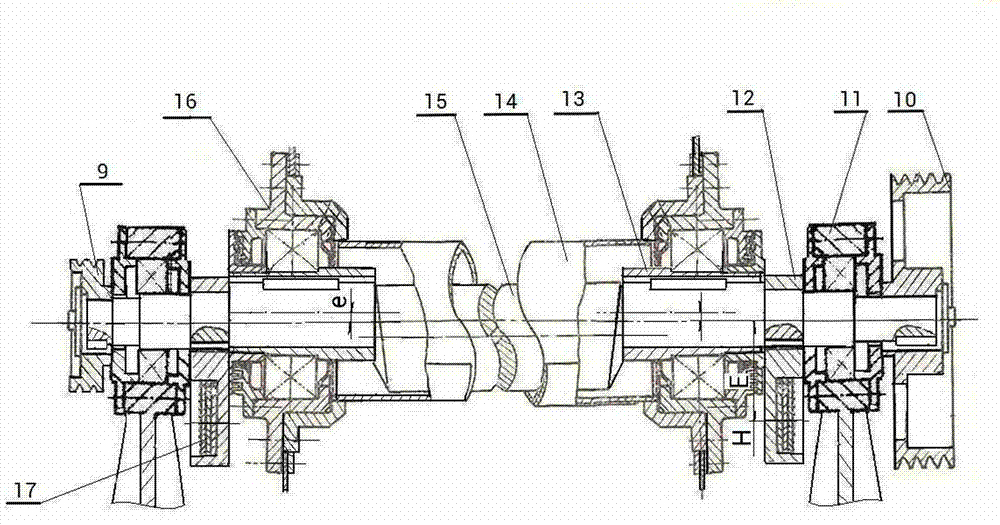

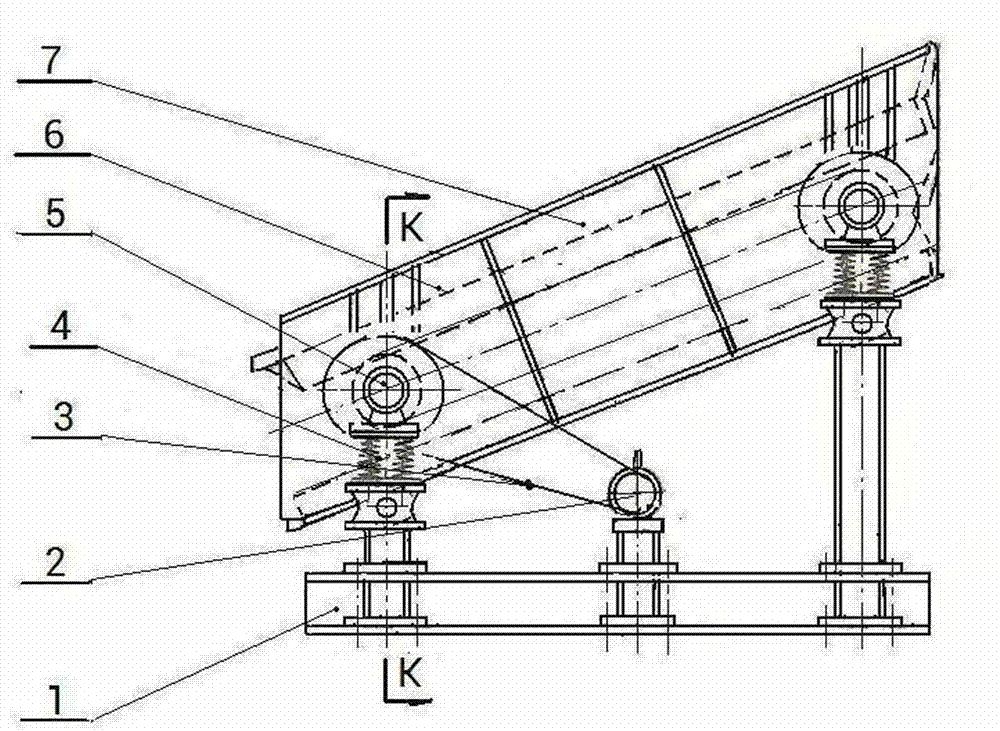

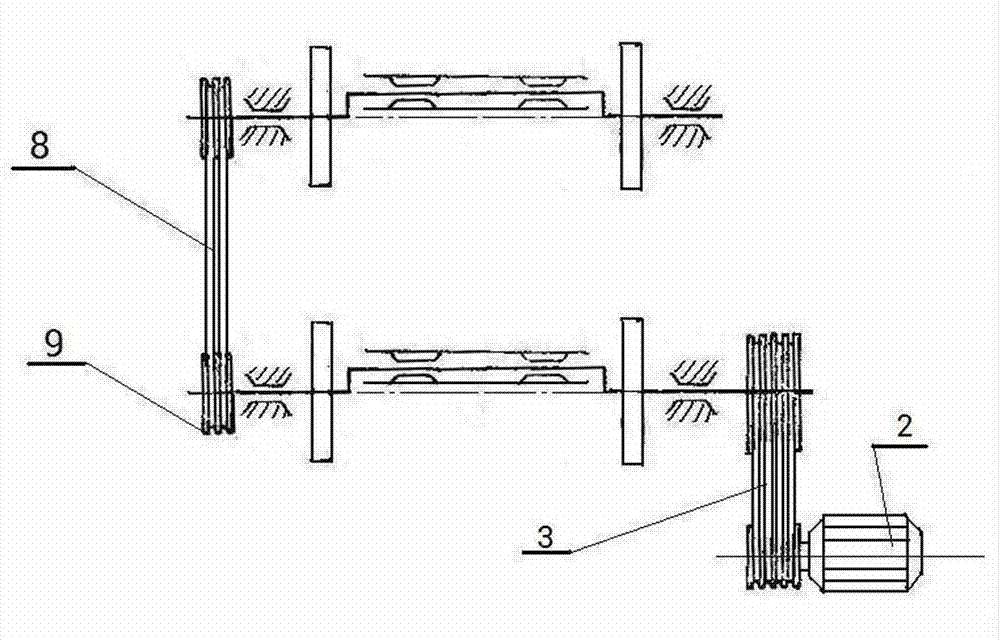

[0067] Such as Figure 1~4 As shown, it is a safe vibration-absorbing vibrating screen of the present invention, including a base 1, a motor 2, a power transmission belt 3, a support spring 4, an excitation balancer 5, a screen 6, a screen box 7, a timing belt 8, and a timing wheel 9 , power wheel 10, main shaft bearing seat assembly 11, eccentric balance plate 12, eccentric sleeve 13, round pipe 14, main shaft 15, screen box bearing assembly 16 and counterweight 17, and the motor 2 is fixed on the frame 1 and connected with the main shaft 15 of the excitation balancer 5 through the power transmission belt 3; Spring 4; the power of the motor 2 is transmitted to the main shaft of the excitation balancer 5 through the power transmission belt 3 to drive the screen box 7 to perform circular motion to classify or dehydrate the material; the excitation balancer 5 includes a synchronous wheel 9, a power wheel 10, Main shaft bearing assembly 11, cylinder 14, main shaft 15 and screen ...

Embodiment 2

[0069] Such as Figure 2-5 As shown, it is a safe vibration-absorbing vibrating screen of the present invention, including a base 1, a motor 2, a power transmission belt 3, a support spring 4, an excitation balancer 5, a screen 6, a screen box 7, a timing belt 8, and a timing wheel 9 , power wheel 10, main shaft bearing seat assembly 11, eccentric balance disc 12, eccentric sleeve 13, round pipe 14, main shaft 15, screen box bearing assembly 16 and counterweight 17, and the described safety vibration-eliminating vibrating screen is Suspension type, the main shaft bearing seat assembly 11 of the excitation balancer is provided with a suspension ring and is suspended on a steel beam through a steel wire rope, and a support spring 4 is provided on the steel beam; the motor 2 is fixed on the frame 1 and connected with the main shaft 15 of the excitation balancer 5 through the power transmission belt 3; the screen box 7 is arranged at the eccentric position of the main shaft 15 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com