Continuous casting equipment, cast rod manufactured by using the same, and manufacturing method of the cast rod

A technology for casting molds and ingots, which is applied to continuous casting devices and casting rods manufactured by using the device and its manufacturing field, which can solve the problems of increased liquid resistance, difficulty in reducing the opening of filters, and difficulty in obtaining high-quality casting rods, etc. problem, to achieve the effect of improving efficiency and improving removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

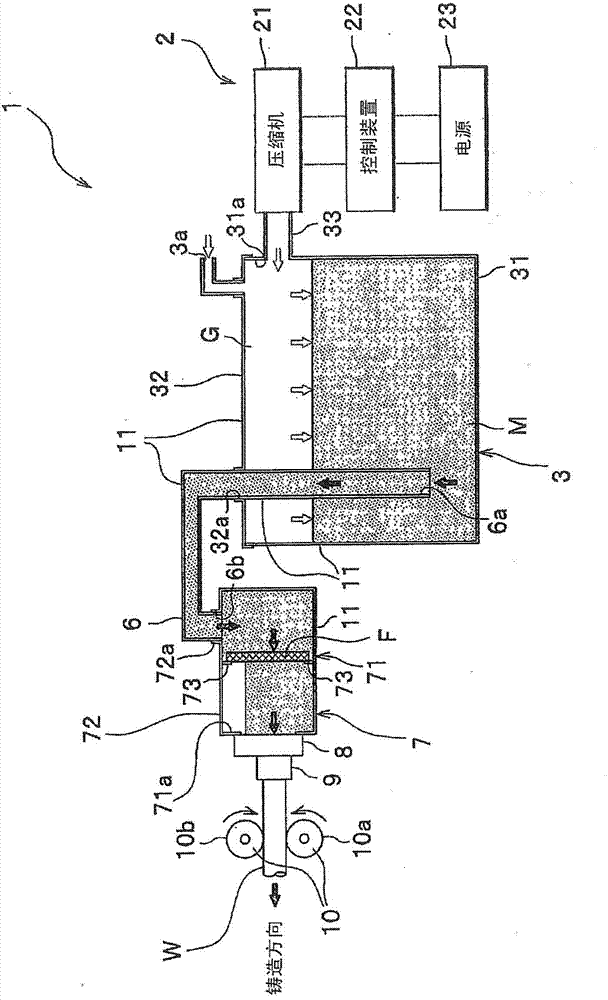

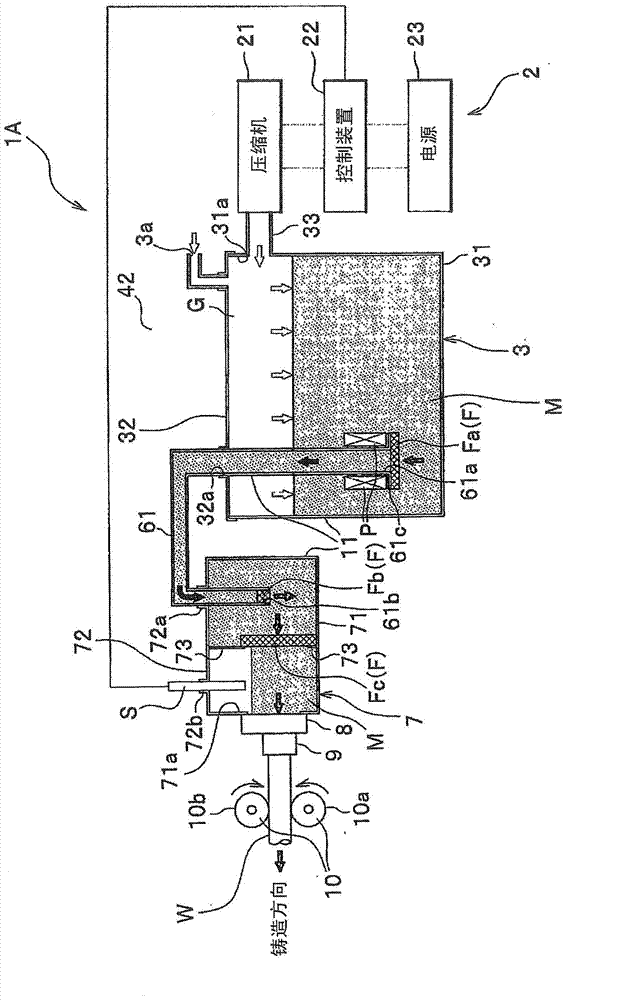

[0067] Below, refer to figure 1 as well as figure 2 Embodiments for carrying out the present invention will be described.

[0068] "Construction of continuous casting equipment"

[0069] Such as figure 1 As shown in the continuous casting apparatus 1, for example, when the molten metal M flowing in the molten metal path 11 is solidified in the mold 9 to continuously cast the cast rod W (ingot), the cast rod W is cooled by a cooling device (not shown). , a device for continuous casting casting rod W simultaneously. The continuous casting device 1 includes a melting furnace (not shown in the figure), holding furnace 3, pressurizing device 2, liquid supply pipe 6, tundish 7, filter F, mold mounting plate 8, mold 9, and transfer device 10, which will be described later. . The continuous casting apparatus 1 may be a so-called horizontal (horizontal) apparatus or may be a vertical apparatus. Hereinafter, a horizontal apparatus will be described as an example.

[0070] 《Consti...

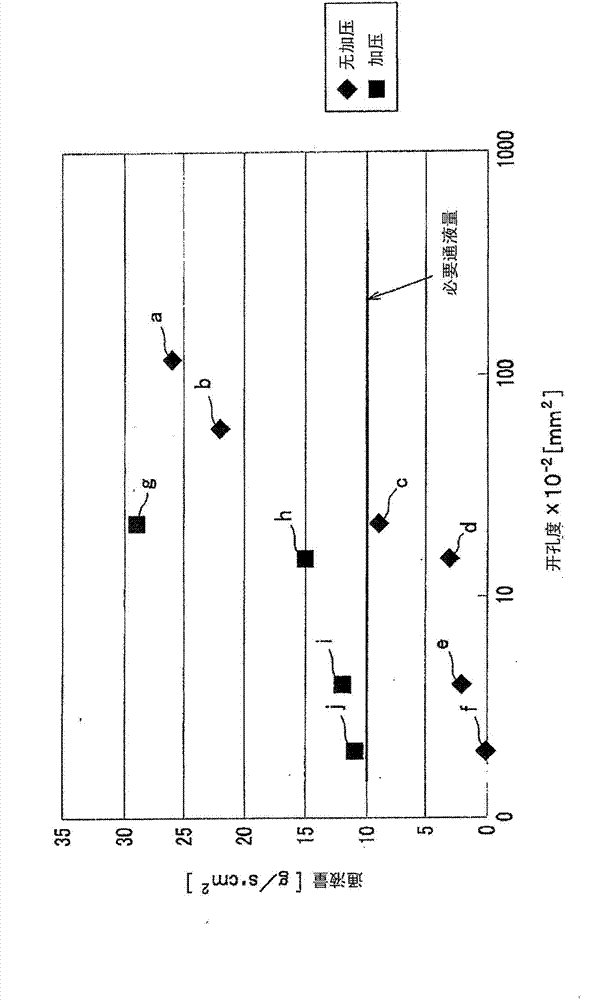

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com