Simple fixing and clamping device of large-sized wallboard

A holding device and large-scale wall plate technology, applied in the field of sheet metal forming, can solve the problems of inability to adapt to changes in the curvature of the curved surface, complex structure, poor compatibility, etc., and achieve a simple holding device structure, good compatibility, good versatility and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a simple and simple holding device for large wall panels.

[0021] This example is used for integral wall panels within the range of 1600mm×1200mm.

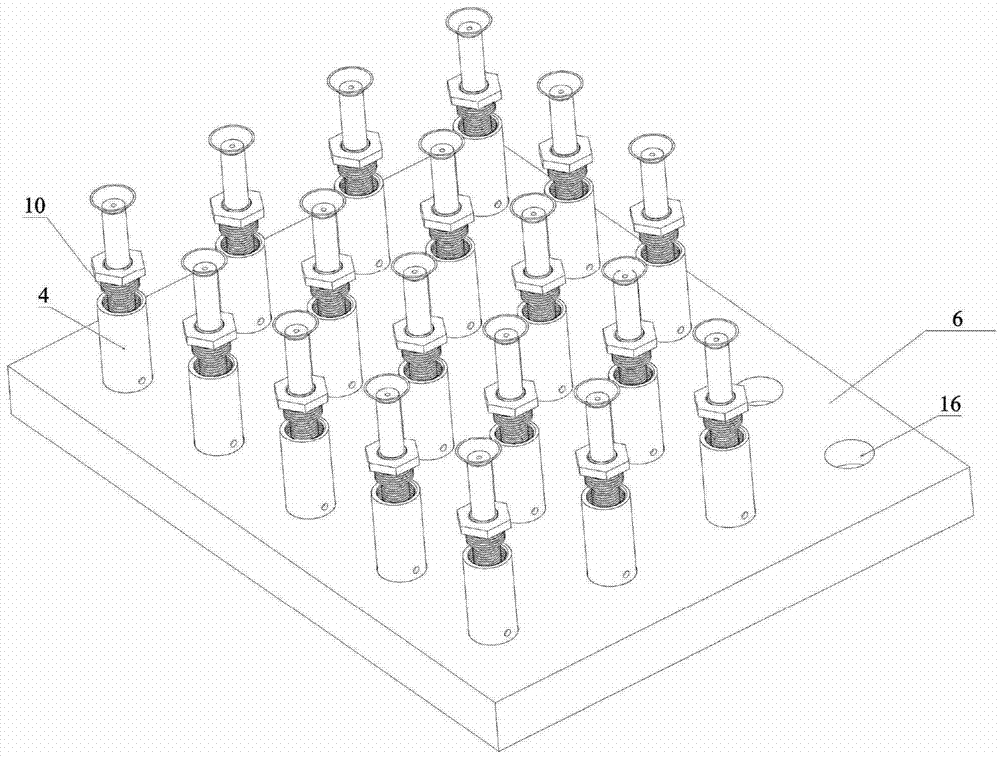

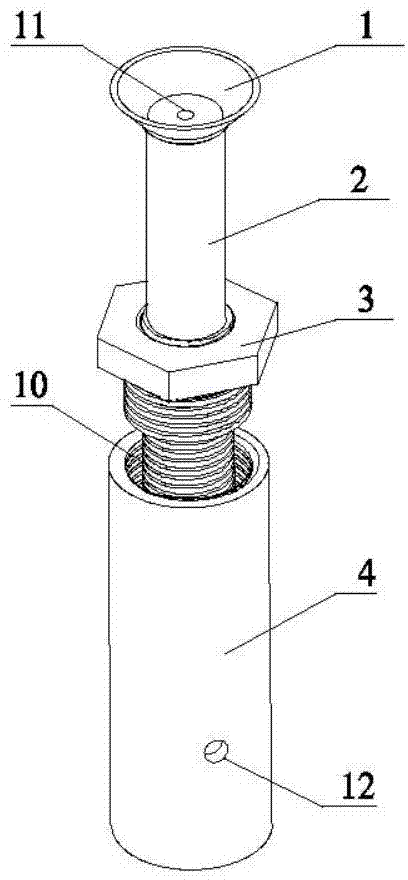

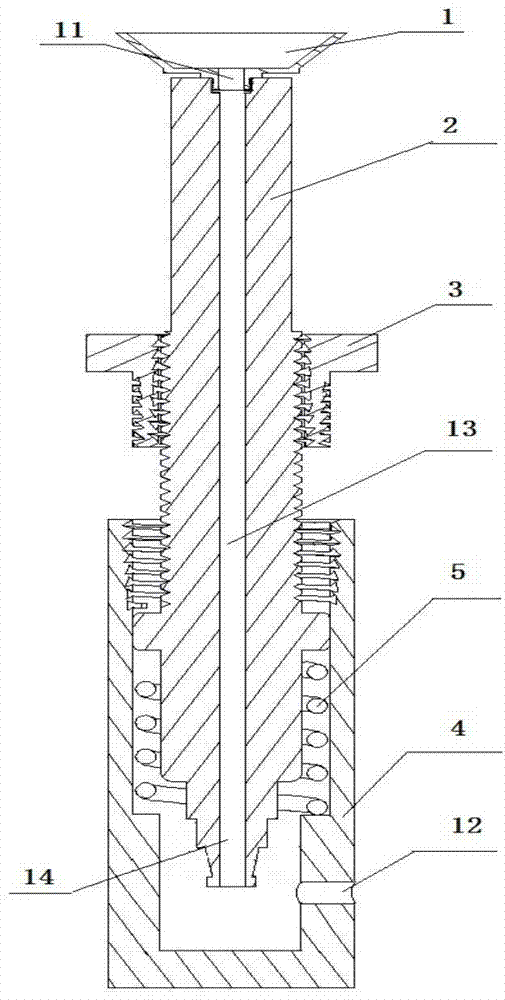

[0022] refer to Figure 1 to Figure 4 , the simple holding device for large wall panels consists of a vacuum generator 8, an air compressor 9, a base plate 6, a vacuum hose 7, and a number of sucker devices 10; the air compressor 9 is connected to the vacuum generator 8, and the air compressor 9 is connected to the vacuum generator Device 8 is installed on the outside of base plate 6, and some base plate blind holes 16 are evenly distributed on the base plate 6, and the support column 4 of suction cup device 10 is fixed in the base plate blind hole 16, and support column 4 and base plate blind hole 16 are transition fits. The support column 4 is placed in the blind hole 16 and fixed on the base plate by welding. In this example, Q235 steel is selected as the material of the bottom plate 6, the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com