A kind of dust-free unloading and pretreatment method of cassava raw material

A pretreatment and cassava technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem of high personnel costs and train delay costs, environmental pollution around the transportation route, and high sand content of cassava slurry, etc. problems, to achieve the effect of reducing cassava dust flying, good social benefits, and improved visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the specific embodiments of the present invention are clearly and completely described below, and preferred embodiments of the present invention are illustrated in conjunction with the accompanying drawings:

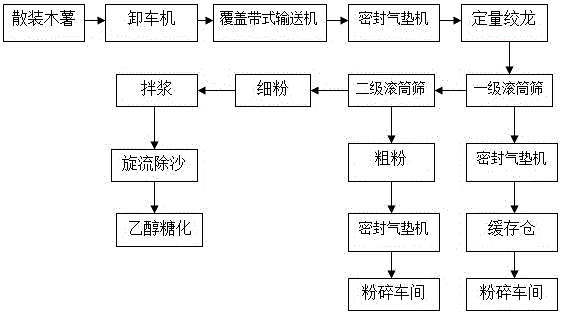

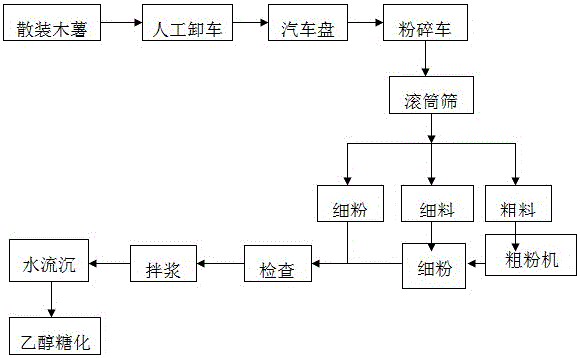

[0024] In practice, the present invention aims at figure 2 According to the objective problems existing in the traditional process flow, the comprehensive and in-depth research on the existing process technology route and equipment performance principle, it is believed that the cassava unloading and pulp mixing and sand removal process should be transformed according to the actual production situation. The specific transformation process is as follows figure 1 shown.

[0025] Since the problem to be solved in the unloading of cassava is to eliminate the dust pollution of cassava raw materials and improve the unloading efficiency, through the analysis of the physical and chemical properties of cassava itself, referring to the unloading m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com