Extraction method of odorless perillaldehyde with high stability

An extraction method and high stability technology, applied in the field of high stability and odorless perilla aldehyde extraction, can solve the problems of complex operation, high production cost, odor, etc., achieve high color price, high yield, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

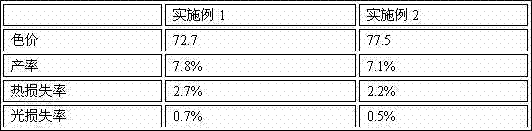

Embodiment 1

[0020] (1) Pressing of raw materials: select 20 kg of perilla with deep color, no frostbite, no rot, no pests and diseases, wash and remove impurities such as sediment, and put it into the press for pressing;

[0021] (2) Ultrasonic treatment: Then place it in an ultrasonic instrument at 40°C, control the conditions at 0°C, ultrasonic power at 100W, ultrasonic frequency at 40KHZ, and ultrasonically treat for 35 minutes;

[0022] (3) Extraction: Centrifuge perilla juice at 3000r / min for 8min to extract;

[0023] (4) Concentration by reflux: put the extract in the reflux tube for reflux for 1 hour, and distill the reflux liquid under atmospheric pressure;

[0024] (5) Adsorption and elution: Put the fraction on HPD100 macroporous resin adsorption column, adsorb at a flow rate of 20M3 / h, and elute with 80% ethanol solution;

[0025] (6) Membrane treatment: use AHP ultrafiltration membrane at 2.5kg / cm 2 , under the condition of 25 ℃, add 35ml water to the treated solution, use N...

Embodiment 2

[0028] (1) Pressing of raw materials: select 20 kg of perilla with deep color, no frostbite, no rot, no pests and diseases, wash and remove impurities such as sediment, and put it into the press for pressing;

[0029] (2) Ultrasonic treatment: Then place it in an ultrasonic instrument at 50°C, control the conditions at 5°C, ultrasonic power 100W, ultrasonic frequency 50KHZ, and ultrasonic treatment for 45 minutes;

[0030] (3) Extraction: extract perilla juice by centrifuging at 3500r / min for 12min;

[0031] (4) Concentration by reflux: put the extract in the reflux tube for reflux for 1.5 hours, and distill the reflux liquid under atmospheric pressure;

[0032] (5) Adsorption and elution: put the fraction on the XDA-8 macroporous resin adsorption column, adsorb at a flow rate of 60M3 / h, and elute with 85% ethanol solution;

[0033] (6) Membrane treatment: use AHP ultrafiltration membrane at 3.0kg / cm 2 , under the condition of 30°C, add 40ml water to the treated solution, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com