High-silent type energy-saving vacuum toilet system

An energy-saving and silent technology, applied in flushing toilets, water supply devices, buildings, etc., can solve problems such as low vacuum, insufficient atmospheric pressure, weak suction, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

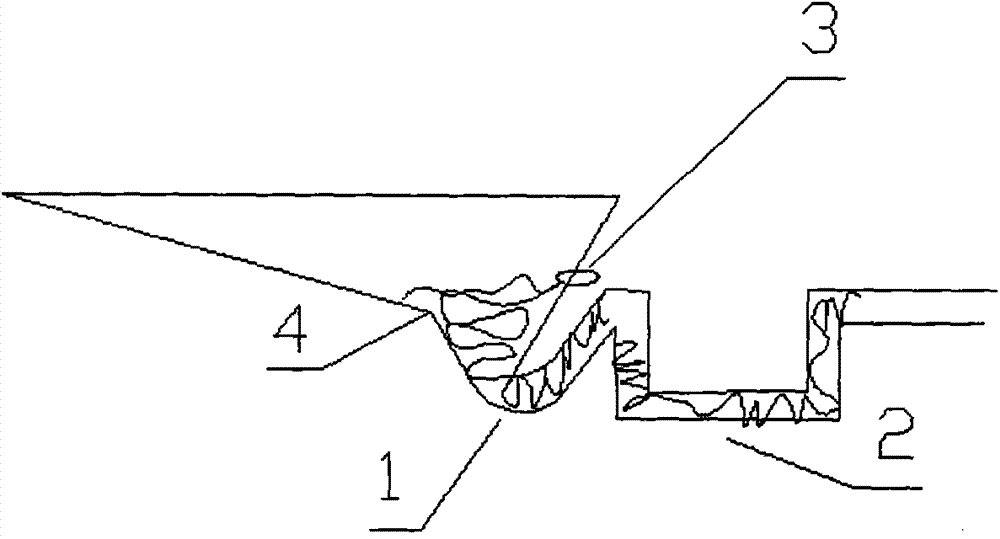

[0024] The first water trap (1) plays the role of avoiding odor and increasing the flow rate, and the second water trap (2) forms a water column, which seems to pull the piston in the pipeline when the toilet is drawn.

[0025] When the toilet is pumped out, the piston is pulled by the action of the second trap (2), and the inside of the toilet is a conical horizontal liquid level drain (4) from the inside of the toilet to the mouth of the pipeline. The inner wall of the toilet flows down at the same speed, and the piston effect is formed by the rear pipe, so that the level of the liquid level in the toilet can be lowered, so that the air from the toilet to the mouth of the first trap pipe basically does not enter, greatly reducing the noise. Can achieve the comfort of advanced siphon toilet.

[0026] When there is too much liquid in the toilet (such as after washing the mop), the probe probe (3) on the second trap (2) works at this moment, and when the liquid inside the toile...

Embodiment 2

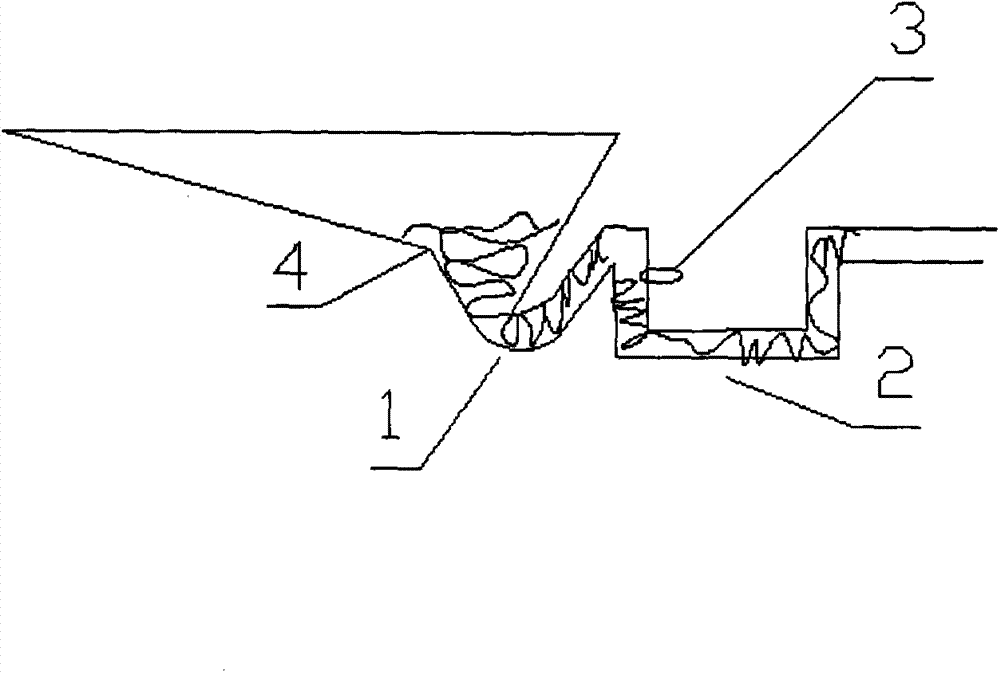

[0028] The first water trap (1) plays the role of avoiding odor and increasing the flow rate, and the second water trap (2) forms a water column, which seems to pull the piston in the pipeline when the toilet is drawn.

[0029] After pressing the flushing button, the toilet is flushed and then pumped. Before the toilet is pumped, the probe probe (3) is soaked in the liquid. When the toilet is pumped, it is the same as the principle of scheme 1. The liquid level in the toilet drops. When the liquid level leaves the probe When the needle probe (3) is used, the electrode is disconnected, and the controller will delay the toilet pumping action after receiving the signal, so as to pump the liquid through the first water trap (1) and then lie down to avoid odor. It is also a liquid piston Flow, basically no air enters, greatly reduces noise, and can achieve the comfort of a high-grade siphon toilet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com