Three-screw pump

A three-screw pump and screw technology, which is applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of large gap between the active screw and driven screw, low volumetric efficiency of the three-screw pump, and decreased volumetric efficiency, and achieve flow Stable, avoid deformation of processing and assembly, optimize the effect of meshing seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

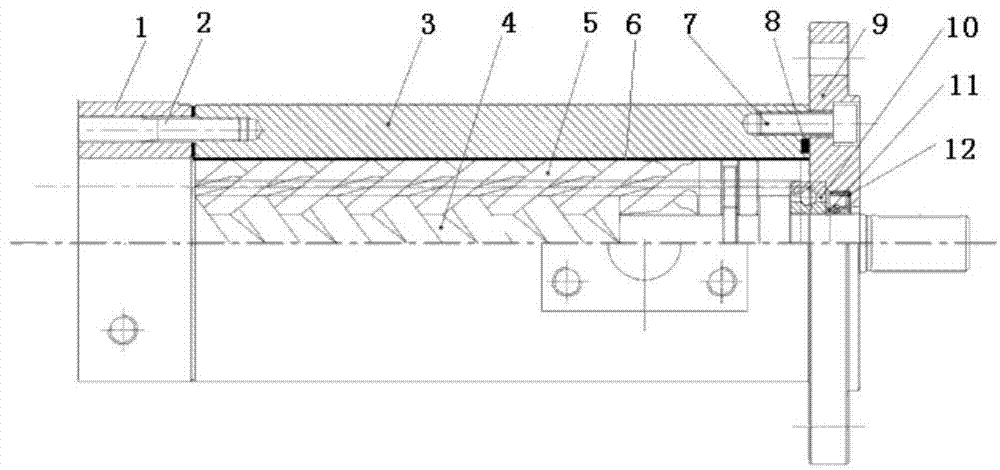

[0022] refer to figure 1 , the three-screw pump of the present invention includes a pump body 3, a driving screw 4 and two driven screws 5, a bushing 6 is axially installed between the pump body 3 and the driven screw 5, and the driving screw 4 and the driven screw 5 engage Located in the bushing 6, the two ends of the pump body 3 are respectively equipped with a front cover 9 and a rear cover 1, a gasket is provided between the pump body 3 and the rear cover 1, and the pump body 3 and the rear cover 1 are connected by screws, and the active The screw 4 is installed on the front cover 9 through the bearing 10, an O-ring 8 is provided between the pump body 3 and the front cover 9, the pump body 3 and the front cover 9 are connected by a fixing piece 7, and the active screw 4 is installed on the front cover 9 There is a retaining ring 11, a seal 12 is arranged between the retaining ring 11 and the bearing 10, the driving end of the driving screw 4 extends to the outside of the ...

no. 2 example

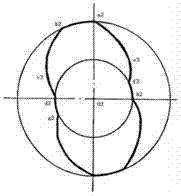

[0029] Improvement is made on the basis of the first embodiment, and the Archimedes spiral is replaced by the Archimedes-like spiral, and the polar radius equation of the Archimedes-like spiral is ρ=α×f(t)+β , where the equation ρ=α×f(t)+β is continuous and the first-order derivative is continuous, that is, dρ / dt=0 at the two endpoints of the starting point and the ending point, so a curve satisfying the condition can be selected, where α and β is a constant.

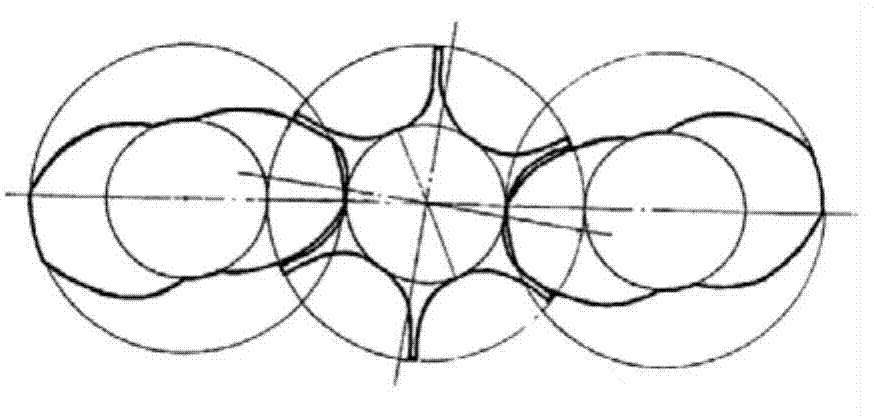

[0030] The number of screw heads of the active screw 4 is 2n (n=1, 2, 3...), the tooth profile of each screw is the same, and is evenly distributed along the circumference, and the tooth profile of one screw is formed by the arc line a1b1, Archimedes-like The spiral b1c1, the dedendum arc line c1d1, the Archimedes-like spiral d1e1, the arc line e1f1, and the addendum arc line f1g1 are sequentially connected, among which, the dedendum arc line c1d1 and the addendum arc line f1g1 is the arc line with the center O1 of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap