Empty oil conversion supercharging device

A technology of supercharging device and air-oil, which is applied in the direction of fluid pressure actuating device, fluid pressure converter, servo motor, etc., can solve the problems of large volume, single function, limited space conditions, etc., to reduce friction loss of piston, mechanism Compact, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

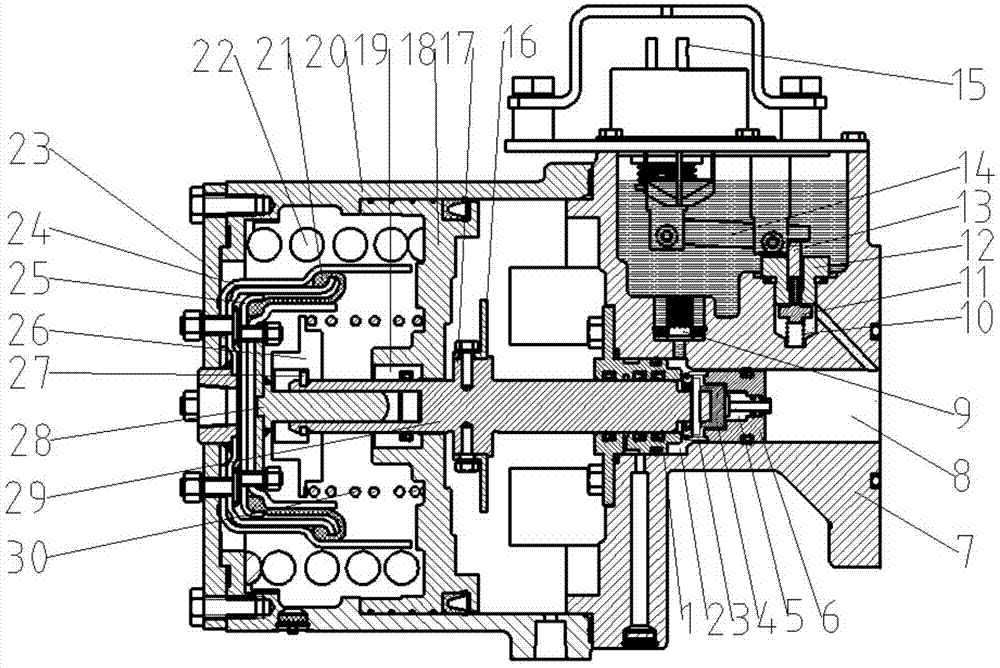

[0038] The air-oil conversion supercharging device of this embodiment includes a wind pressure cylinder, an energy storage cylinder, a piston, a pressure relief device and an oil pressure cylinder 8;

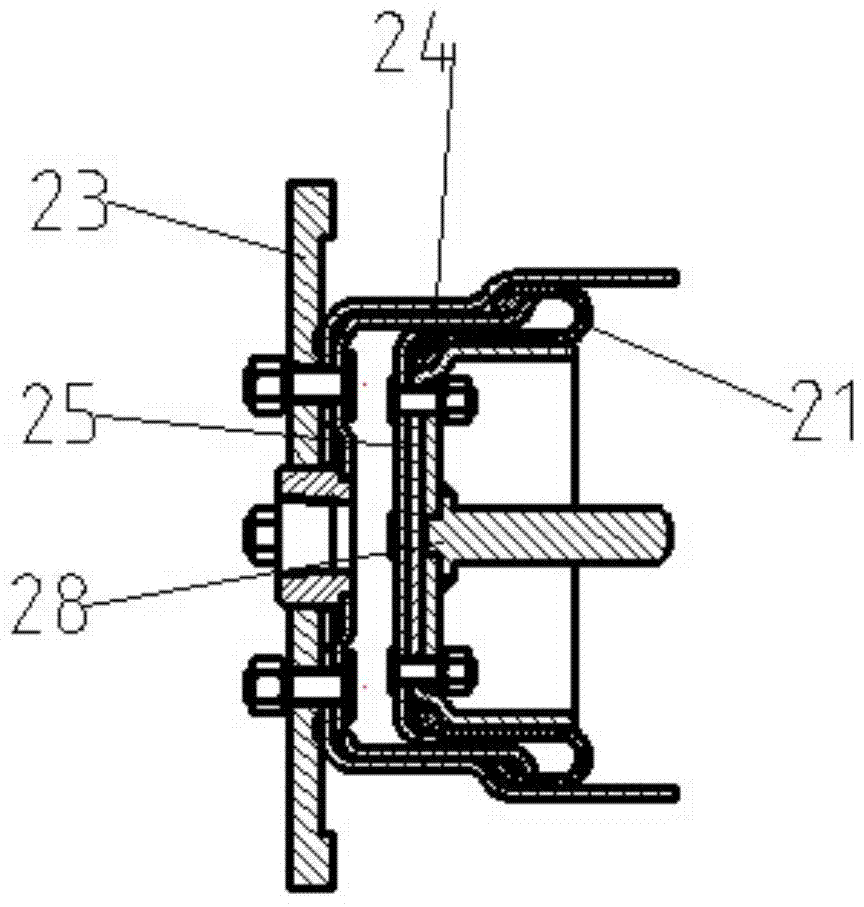

[0039] The air pressure cylinder consists of an airbag outer splint 24, an airbag inner splint 25, an airbag return spring 30 and an airbag 21, the airbag outer splint 24 is fixedly connected with the cylinder head 23, the airbag inner splint 25 is fixedly connected with the piston seat 28, and the airbag outer splint 24 is connected with the cylinder head 23. The splint 25 in the airbag clamps the outer end and the inner end of the airbag 21 respectively; one end of the airbag return spring 30 is connected with the energy storage piston 18, and the other end is connected with the spring seat 26, and the spring seat 26 is sleeved on the piston rod 29 and Located between the retaining ring 27 at the left end of the piston rod 29 and the energy storage piston 18;

[0040] The ener...

Embodiment 2

[0046] The air-oil conversion supercharging device of this embodiment includes a wind pressure cylinder, an energy storage cylinder, a piston, a pressure relief device and an oil pressure cylinder 8;

[0047] The air pressure cylinder consists of an airbag outer splint 24, an airbag inner splint 25, an airbag return spring 30 and an airbag 21, the airbag outer splint 24 is fixedly connected with the cylinder head 23, the airbag inner splint 25 is fixedly connected with the piston seat 28, and the airbag outer splint 24 is connected with the cylinder head 23. The splint 25 in the airbag clamps the outer end and the inner end of the airbag 21 respectively; one end of the airbag return spring 30 is connected with the energy storage piston 18, and the other end is connected with the spring seat 26, and the spring seat 26 is sleeved on the piston rod 29 and Located between the retaining ring 27 at the left end of the piston rod 29 and the energy storage piston 18;

[0048] The ener...

Embodiment 3

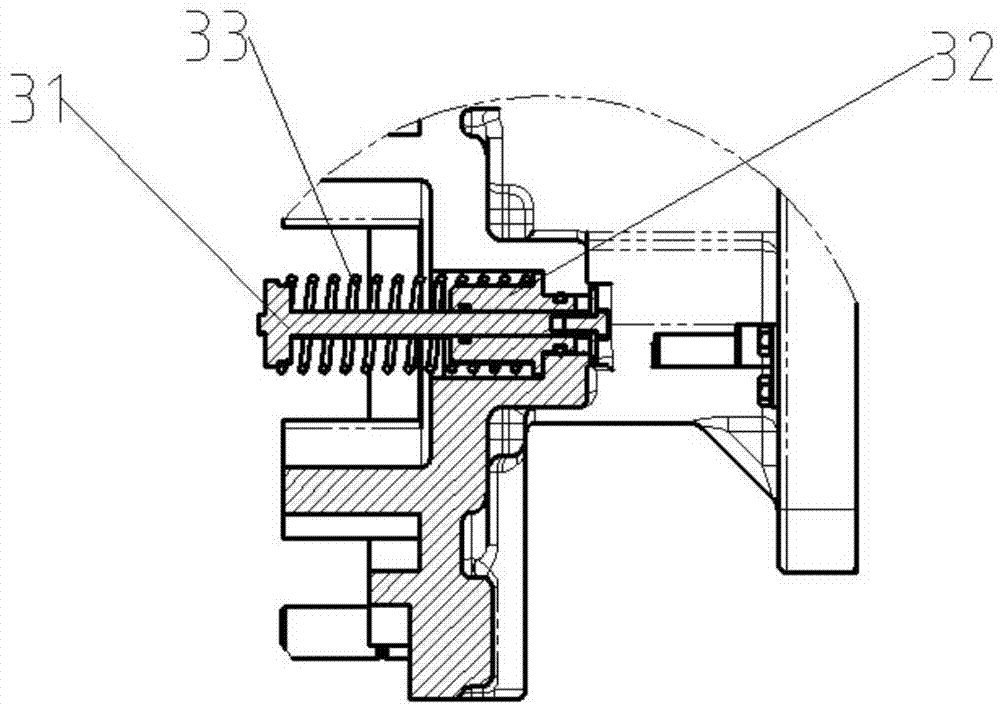

[0058] The air-to-oil conversion supercharging device of this embodiment is the same as Embodiment 2 except for the following differences:

[0059] The piston rod 29 is provided with an amplitude disc 16, which is in contact with the stroke display rod 31, and the stroke display rod 31 passes through the guide sleeve 32 to connect with the travel gauge; Stick 31 is connected.

[0060] The pressurization process of the wind pressure cylinder is as follows: the energy storage cylinder 20 is in the state of air filling and relief, and the wind pressure cylinder is charged with air, the piston seat 28 moves under the action of air pressure, and the movement and force are transmitted to the hydraulic piston 6 through the piston rod 29 At this time, the sealing briquetting block 4 presses the one-way valve 5, the one-way valve 5 closes the hydraulic cylinder 8, and the force of the hydraulic piston 6 is finally converted into hydraulic pressure output.

[0061] The working process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com