Induction type water faucet based on pilot structure

An inductive, faucet technology, applied in the valve shell structure, the device used to relieve pressure on the sealing surface, the valve operation/release device, etc., can solve the problems of high energy consumption and the overall structure is not flexible enough to avoid The waste of water resources, the simple and flexible mechanism design, the effect of reducing the opening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

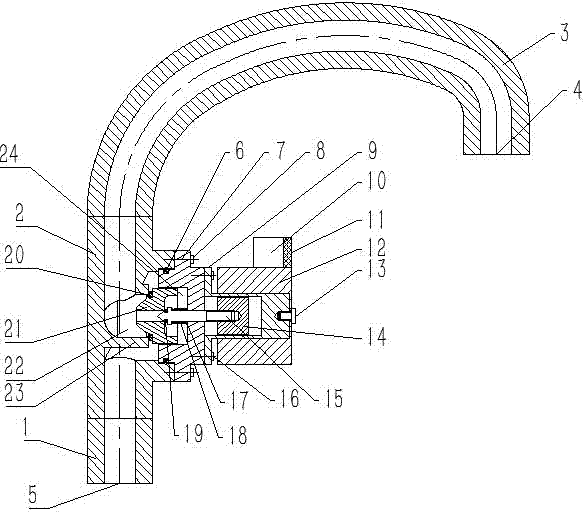

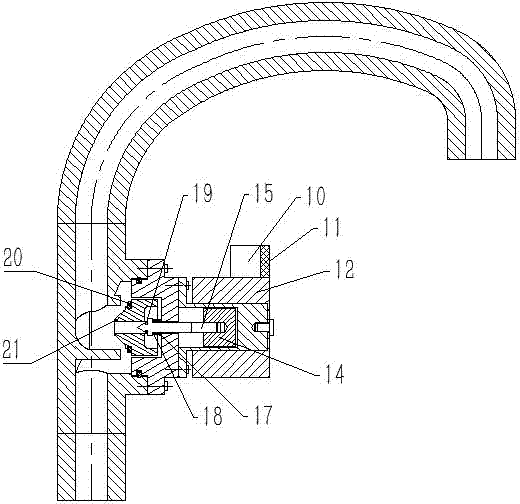

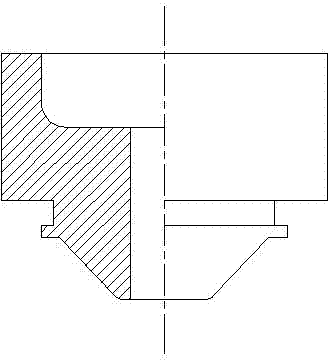

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment includes a water pipe main body. The water pipe main body includes three parts: the bottom 1 of the main body, the middle part 2 of the main body, and the top 3 of the main body. The main body cover 7 is connected, and the main body cover sealing ring 6 is arranged between the main body cover 7 and the main body middle part 2. The main body cover 7 is fixedly connected with a static armature seat 9, and an electromagnetic coil 12 is provided outside the static armature seat 9. A fixed screw 13 is provided between the top of the static armature seat 9 and the electromagnetic coil 12; a micro-controller 10 and an inductor 11 are fixedly connected above the electromagnetic coil 12, and the micro-controller 10 and the inductor 11 are connected by wires; the static armature seat 9 A movable armature 14 is arranged in the internal clearance, and a small piston rod 15 is provided for the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com