Method and system for extracting heat energy of hot dry rocks

A hot dry rock and thermal energy technology, applied in the field of thermal energy extraction from hot dry rock, can solve the problems of low permeability, high loss rate of underground heat exchange fluid, and low porosity, so as to save water resources, avoid blindness and uncontrollability performance, improve the effect of heat extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

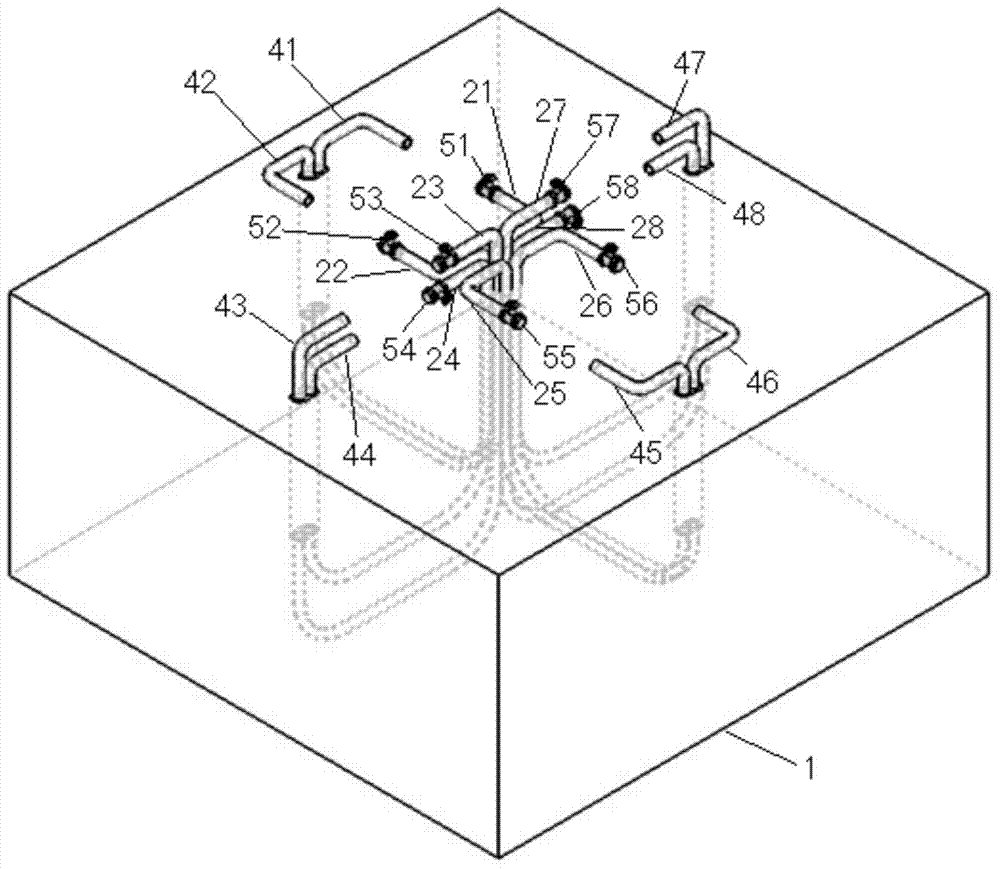

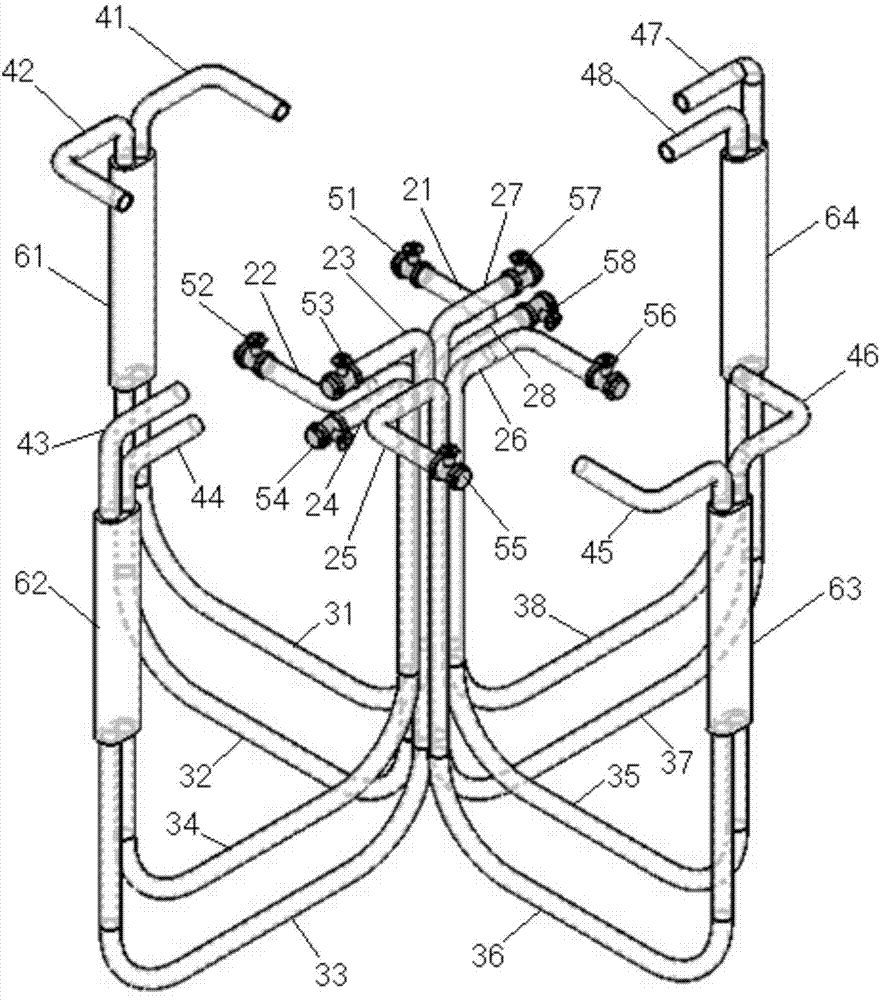

[0040] The high-temperature hot dry rock reservoir 1 is located at a depth of 5000 m underground, and its temperature is 300 °C. Within 30 years of operation of the entire geothermal project, the temperature of the production well is required to be greater than 140°C.

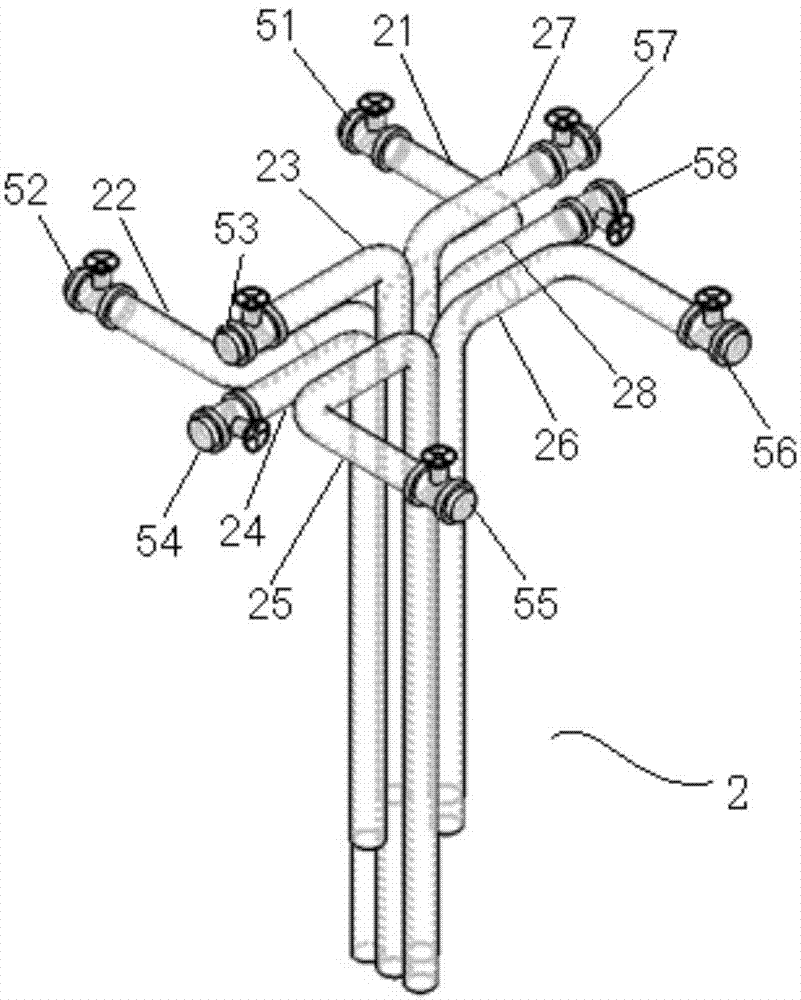

[0041] Injection well system 2, horizontal well system 3 and production well system 4 are constructed according to drilling, cementing and well completion technologies. Among them, in the cementing and completion technology and process operation, it is required that the injection well pipe, horizontal well pipe and part of the production well pipe close to the bottom of the well should be in close contact with the hot dry rock. Materials with good heat transfer performance are filled to minimize the heat transfer resistance between the pipe wall and the hot dry rock. On the other hand, thermal insulation materials should be filled between the pipe wall of the remaining production well pipe and the hot dry rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com