Sample pretreatment method of laser Raman natural gas analyzer and device thereof

A sample pretreatment and analyzer technology, which is applied in the preparation of test samples, etc., and can solve the problems of preheating of unsampled gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

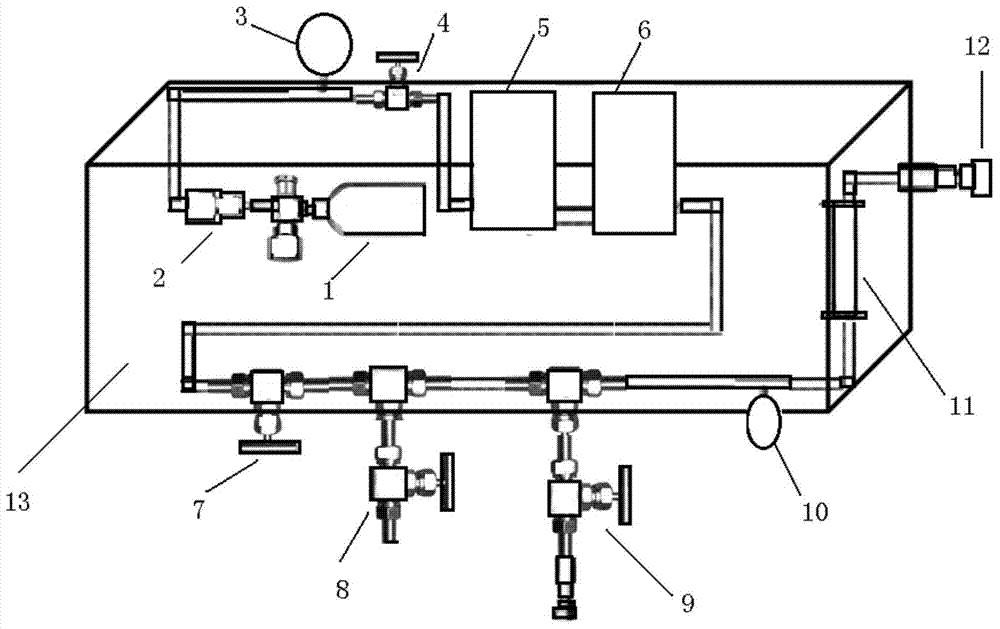

[0017] Embodiment 1: as figure 1 As shown, a sample pretreatment method and device for laser Raman natural gas analyzer, to use laser Raman natural gas analyzer to analyze components as CH 4 (90.0%), C 2 h 5 (2.5%), C 3 h 6 (2.0%), C 4 h 10 (1.5%), C 5 h 12 (1.0%), C6+ (0.6%), N 2 (2.4%), H 2 S (10ppm) natural gas sample pretreatment as an example,

[0018] A sample pretreatment device for a laser Raman natural gas analyzer, the structure of an explosion-proof thermostat 13: a sample bottle 1 is connected to a quick connector 2 of an injection port, and the other end of the quick connector 2 of the inlet is connected to a pressure gauge 3, a first Pressure regulating valve 4, the other end of the first pressure regulating valve 4 is connected to the first filter 5, the other end of the first filter 5 is connected to the second filter 6, and the other end of the second filter 6 is connected to the second pressure regulating valve 7. The other end of the second pressu...

Embodiment 2

[0019] Embodiment 2: as figure 1 Shown, a kind of sample preprocessing method and device for laser Raman natural gas analyzer,

[0020] Open the explosion-proof thermostat 13, put in the sample bottle 1, and connect to the pressure gauge 3, the first pressure regulating valve 4, the first filter 5 (1 μm), and the second filter 6 (0.1 μm) in sequence through the quick connector 2 of the injection port. ), the second pressure regulating valve 7, the vent tee 8, the standard gas inlet 9, the pressure gauge 10, the flow meter 11, and the analyzer interface quick connector 12.

[0021] Close the incubator, turn on the power, heat to 80°C, and keep the temperature constant for 30 minutes. Close the venting tee and the valve at the standard gas inlet, then adjust the first pressure regulating valve 4 and the second pressure regulating valve 7 to purge the gas path, and then connect to the analyzer through the analyzer interface quick connector 12. Due to the heat, the heavy hydroca...

Embodiment 3

[0022] Embodiment 3: as figure 1 As shown, a sample pretreatment device for laser Raman natural gas analyzer, including explosion-proof thermostat, sample bottle base, two-stage filter, pressure gauge, quick connector, pressure regulating valve, three-way connector, pipeline and flow rate count. The sample bottle is installed on the base, and the pressure gauge, pressure regulating valve, primary filter, secondary filter, pressure regulating valve, tee (vent and standard gas inlet), pressure gauge, and flow meter are connected in sequence through quick connectors and pipelines , and finally connected to the quick connector of the analytical instrument.

[0023] The explosion-proof constant temperature box is used to heat the sample and the gas path to vaporize the heavy hydrocarbon components in the natural gas to ensure that the natural gas sample is not distorted. At the same time, the sample gas is preheated to reach the measurement temperature required by the laser Raman ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com