A calibration method based on core gas permeability measuring device

A technology of air permeability measurement and measuring device, which is applied in the field of Kirkland's permeability, can solve the problems of influence of experimental results, reduction of relative error, poor stability of linear flow, etc., and achieve the effect of reducing research cost, reducing relative error, and improving understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

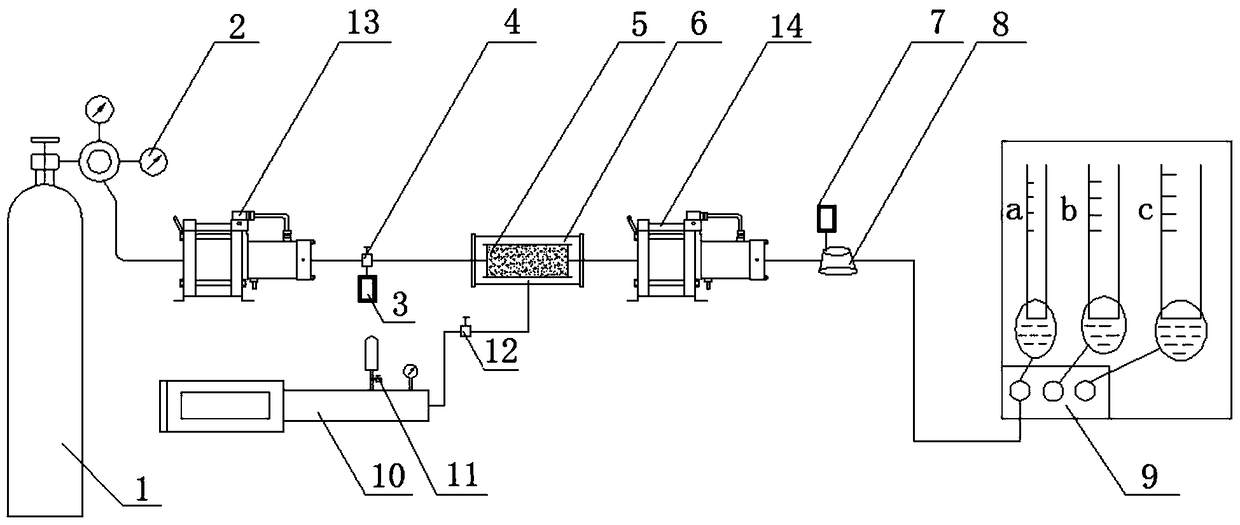

[0021] A device for measuring rock core gas permeability, such as figure 1 As shown, the device includes a core holder 6, one side of the core holder is sequentially connected with a three-way valve 4, a first booster pump 13 and a nitrogen cylinder 1, and the other side is sequentially provided with a second booster pump 14, four One-way valve 8 and soap film flowmeter 9; three-way valve 4 is connected with pressure sensor 3, four-way valve 8 is connected with pressure sensor 7, and rock core holder 6 is also connected with high-pressure manual metering pump 10, and this high-pressure manual metering pump 10 is provided with a drain valve 11, and a ring pressure valve 12 is provided between the high-pressure manual metering pump 10 and the core holder 6.

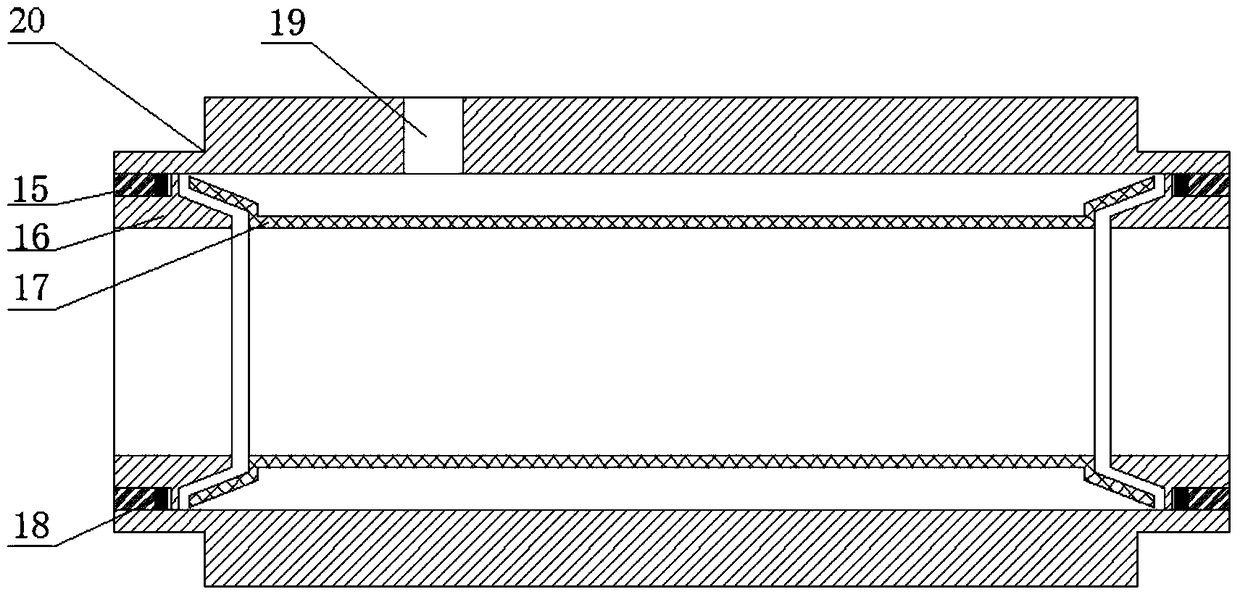

[0022] Such as figure 2 As shown, the core holder 8 includes a cylinder body 20, a core rubber sleeve 17 installed in the cylinder body 20, and sheaths 16 installed on both sides of the cylinder body 20. After the throug...

Embodiment 2

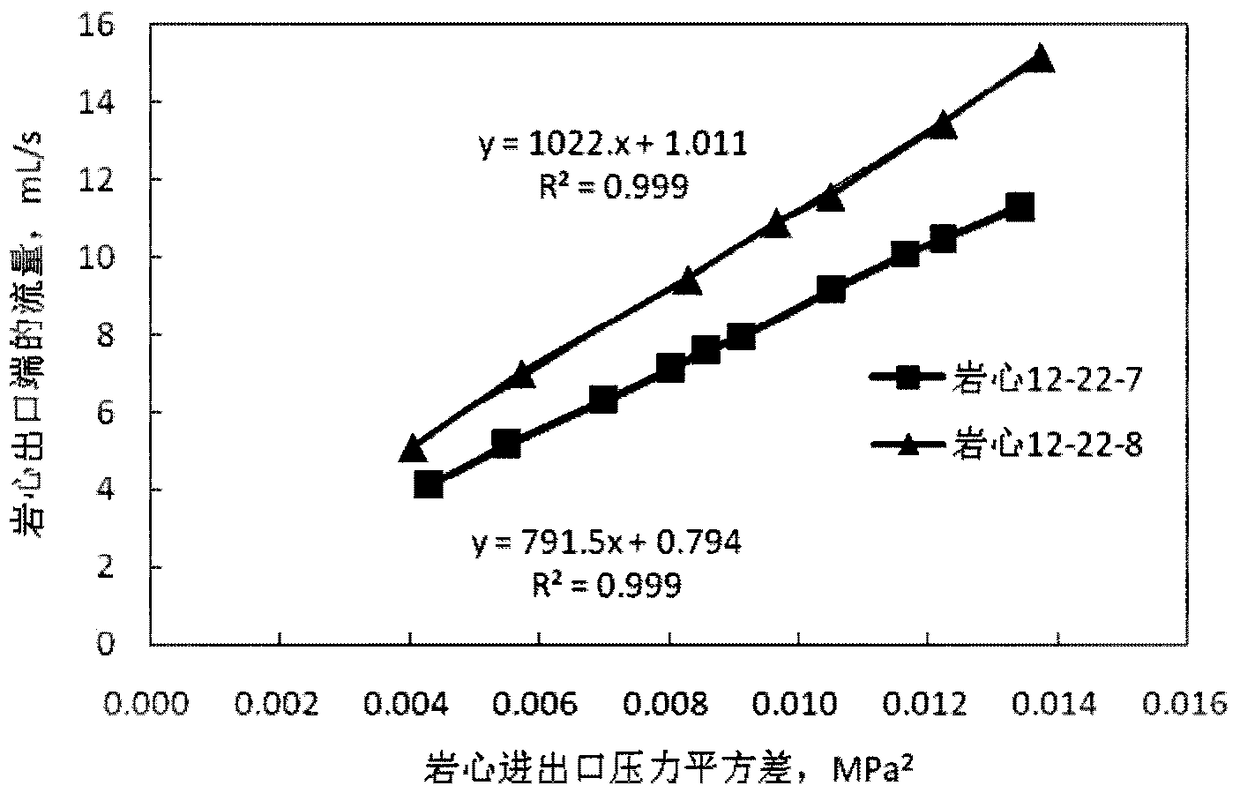

[0025] Measurement of Core Gas Permeability

[0026] Turn on the nitrogen gas to clear the air in the pipeline. Use a vernier caliper to measure the length and width of the section of the rock core 5 to be tested, and calculate the cross-sectional area A. The length L of the rock core 5 is measured. Then the rock core 5 is put into the rock core rubber sleeve 17 in the rock core holder 6, and the rock core 5 is sealed in the rock core rubber sleeve 17 with the sheath 16. Then open the high-pressure manual metering pump 10 and the ring pressure valve 12 to discharge the gas in the annulus of the core holder, close the drain valve 11, rotate the outer wheel of the high-pressure manual metering pump 10 clockwise, pressurize to 5 MPa, and close the ring pressure valve 12 . Open the pressure reducing and stabilizing valve 2 of the nitrogen cylinder 1, the first booster pump 13, the three-way valve 4, the second booster pump 14, the four-way valve 8, and obtain the core inlet pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com