Thermal desorption and sampling device for methyl mercury

A technology of thermal analysis sample injection and methylmercury, which is applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of inability to disassemble and separate control, inability to achieve joint use, inconvenient operation, etc., and achieve simple and efficient testing process, structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

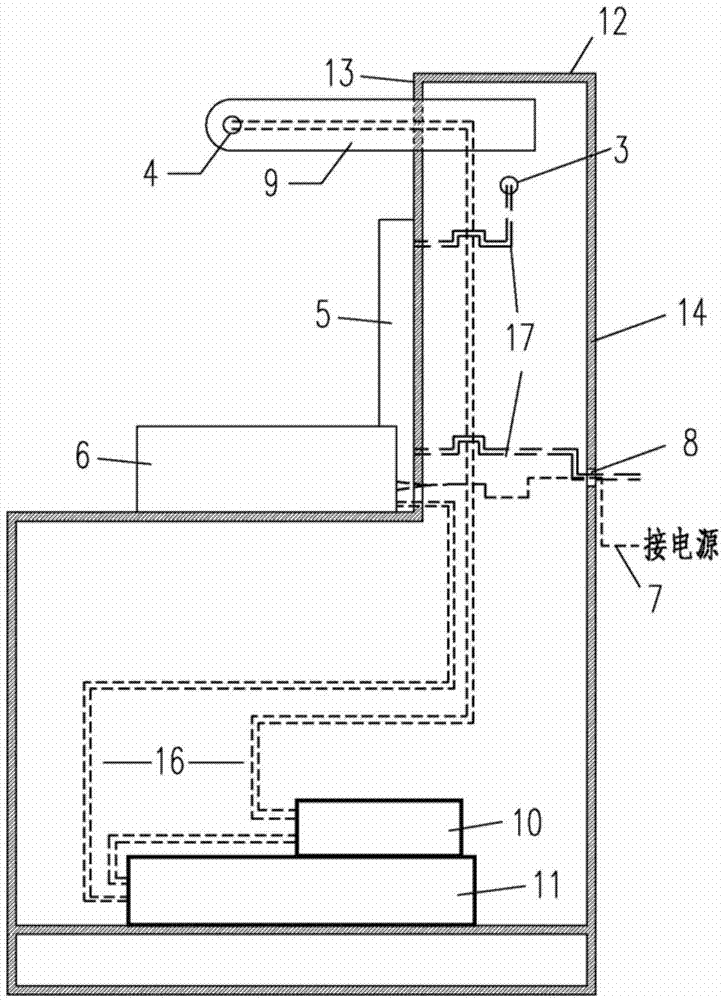

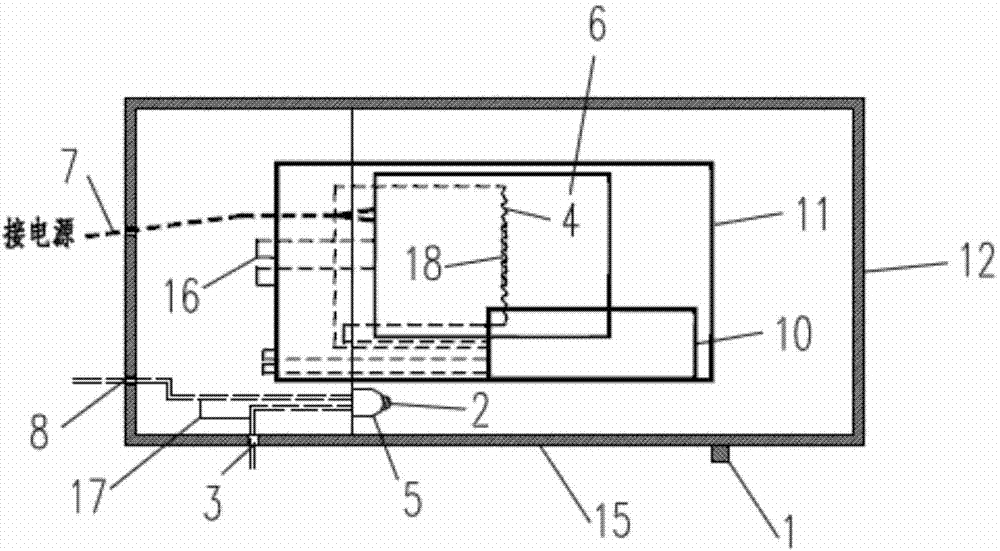

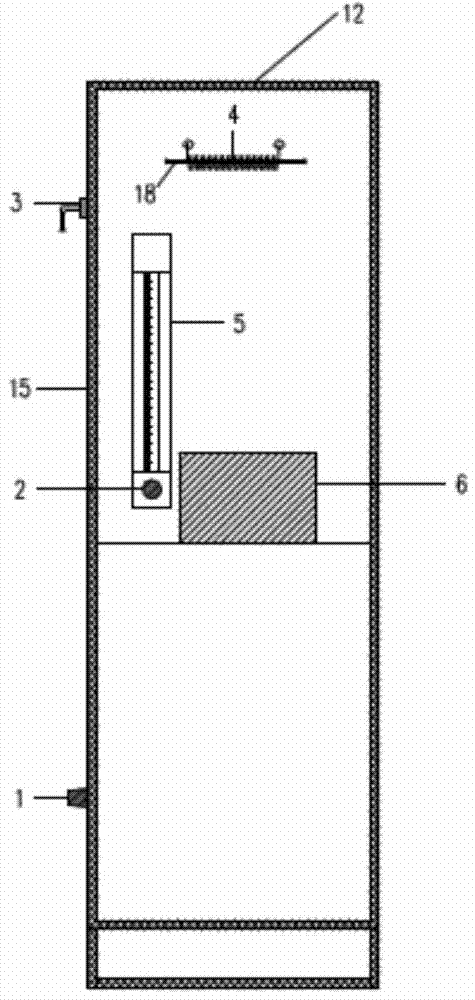

[0018] Attached below Figure 1-5 The technical scheme of the present invention is further described.

[0019] like Figure 1-5 , the present invention provides a methylmercury thermal analysis sampling device, including a flow meter 5, a thermal analysis device and a housing 12, and the thermal analysis device includes a heating coil 4, a heating power supply 11, a heating switch 6 and a heating power supply voltage The regulator 10, wherein the heating switch 6 is a single or double countdown switch.

[0020] The flow meter 5 is a rotameter, and the argon flow can be adjusted through the flow meter knob 2. The flow meter 5 is installed on the front aluminum plate 13 of the methylmercury thermal desorption sampling device, and the lower end passes through the front aluminum plate 13 and then connected The 1 / 8-inch PFA gas pipeline passes through the aluminum plate 14 at the rear of the methylmercury thermal desorption sampling device. Both sides of the aluminum plate use Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com