Suspension device and application method of equivalent salt deposit density insulator

A technology for suspension devices and insulators, applied in the direction of suspension/strain insulators, etc., can solve problems such as difficulty in binding and fixing high-altitude operations, poor suspension stability, irregular operations, etc., and achieve great promotion value, not easy to wear, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

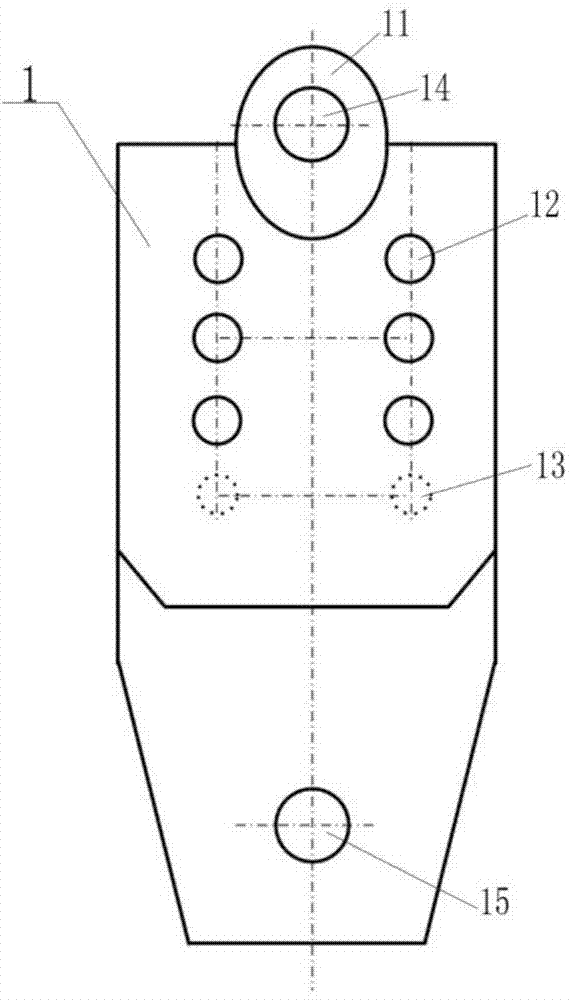

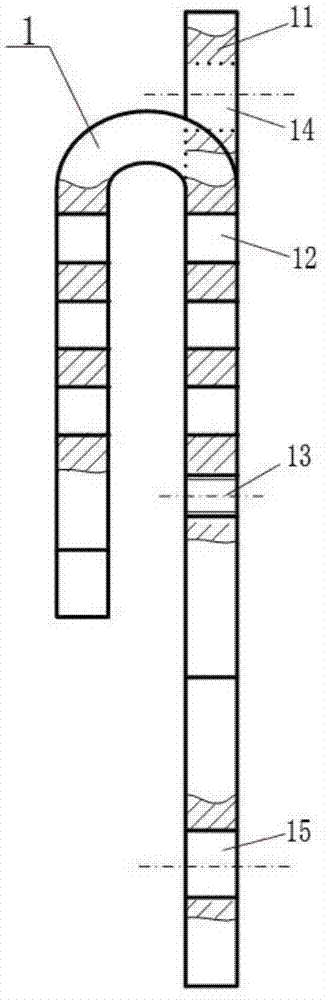

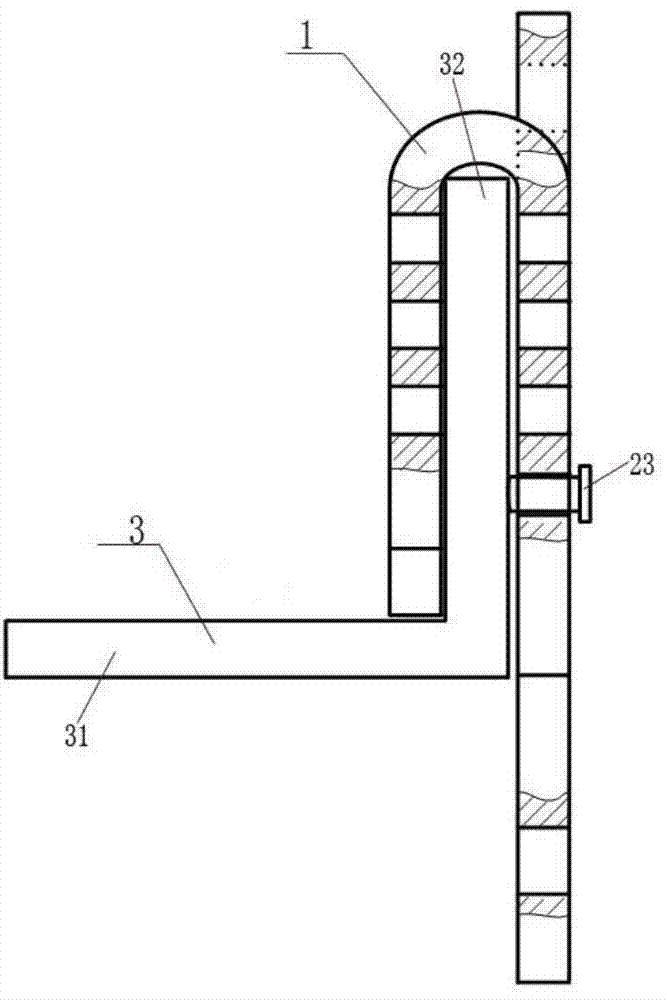

[0046] Such as Figure 1-Figure 2 Shown is a schematic structural diagram of this embodiment. Figure 3-Figure 5 It is a schematic diagram of the use state of this embodiment. The salt-tight insulator hanging plate 1 of this embodiment is made of 8mm thick Q235A steel. In order to meet the requirements for use with various specifications of transmission line tower materials, the width of the U-shaped groove is 13mm, and the distance from the top of the U-shaped groove is 45mm downwards. , set 3 rows and 2 columns of 6 light holes 12 in total, with a vertical spacing of 30mm and a horizontal spacing of 35mm; when in use, the U-shaped notch is clamped on the vertical edge 32 of the iron tower cross arm 3, and according to the height of the vertical edge 32, the The nearest light hole 12 on the top is fixed with bolts 21 and nuts 22. By fixing the bolts 22 in the light holes 12 at different positions, the depth of the U-shaped groove can be adjusted to meet the requirements of s...

Embodiment 2

[0049] Such as Figure 6-Figure 7 Shown is a schematic structural diagram of this embodiment. Figure 8-Figure 9 It is a schematic diagram of the use state of this embodiment. The salt-tight insulator hanging plate 1 of the present embodiment is made of 8mm thick Q235A steel material. In order to meet the requirements for use with various specifications of transmission line tower materials, the opening angle of the U-shaped groove is 45° (the iron tower cross arm 3 adopts equilateral Angle steel production), along the top 45mm, set 3 rows and 2 columns of a total of 6 light holes 12 through, with a vertical spacing of 30mm and a horizontal spacing of 35mm; Bolts 21, nuts 22 and inclined washers 24 are used to fix the light hole 12 closest to the bottom edge 31 of the iron tower cross arm; by fixing the bolt 21 in the light hole 12 at different positions, the depth of the U-shaped groove can be adjusted to meet various requirements. In order to increase the stability of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com