Poultry feed acidifier and preparation method thereof

An acidifier and feed technology, applied in the field of acidifier and its preparation, can solve the problems of difficulty in large-scale popularization and production, high construction cost and high production cost, and achieve the advantages of improving poultry production performance, improving survival rate and reducing bacterial diseases. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Phosphoric acid 21, fumaric acid 10, citric acid 10, formate 15, propionate 15, benzoic acid 5, sodium diacetate 5, palm oil 9, white carbon black 10.

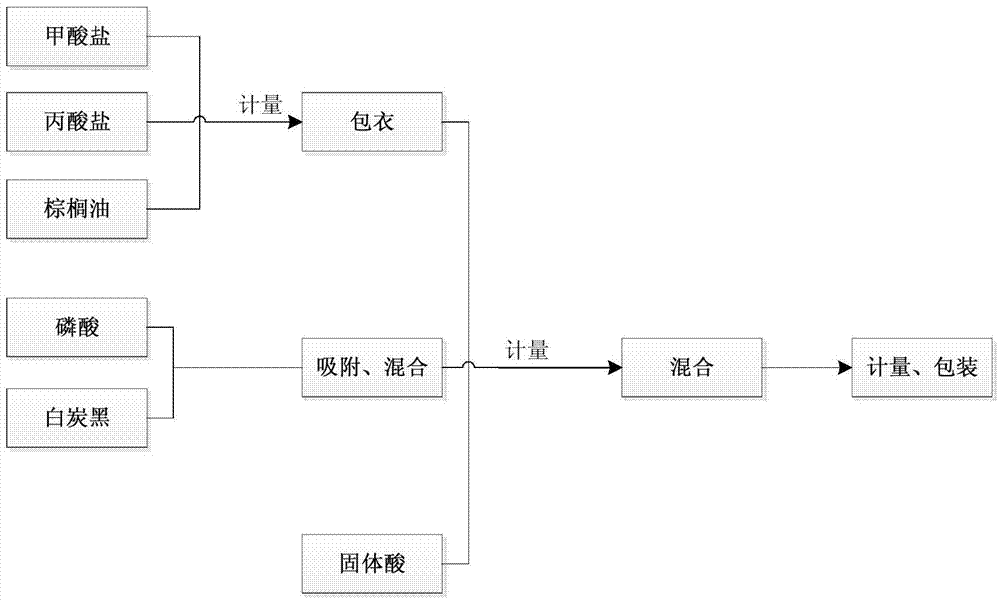

[0030] The preparation process of acidifier for poultry feed is as follows:

[0031] (1) prepare materials according to the above composition and ratio;

[0032] (2) Carry out fluidized bed coating process with calcium formate and calcium propionate with palm oil according to formula requirements;

[0033] (3) Adsorb and mix phosphoric acid and white carbon black according to the formula requirements, then add the coated semi-finished product and solid acid to mix, and finally pass through a 60-mesh grading sieve to obtain the product.

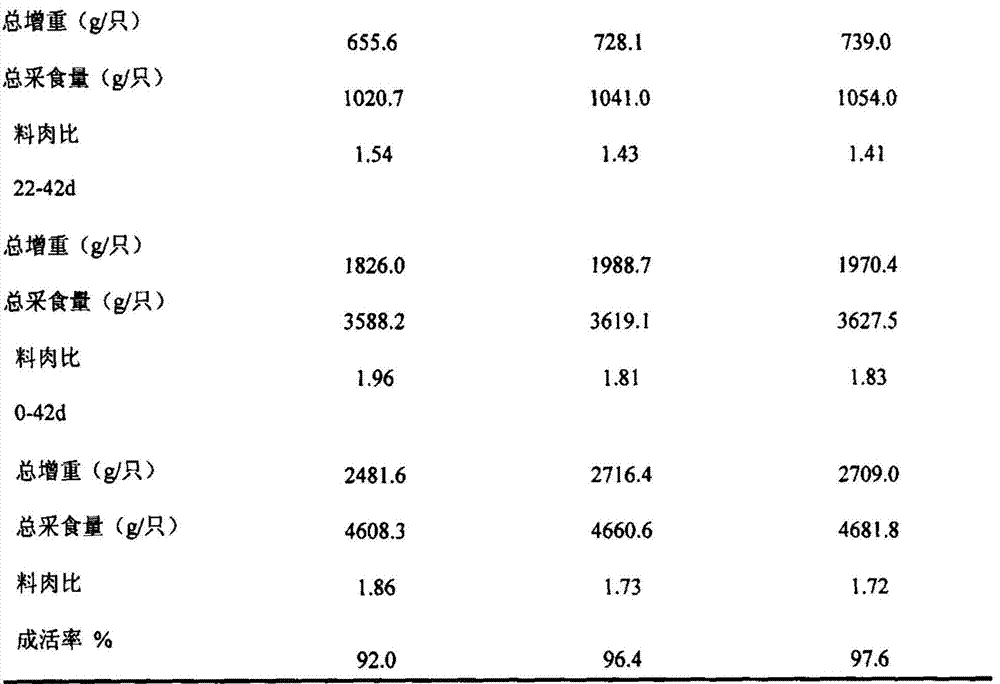

[0034] The product effect verification test results are shown in Table 1

[0035] Table 1

[0036]

[0037]

[0038] According to the test results, it is found that the addition amount of 0-21d is 1.5kg / T, and the addition amount of 22-42d is 1.0kg / T is better.

Embodiment 2

[0040] Phosphoric acid 29, fumaric acid 6, citric acid 6, formate 15, propionate 15, sodium diacetate 5, palm oil 10, white carbon black 14.

[0041] The preparation method is the same as in Example 1.

[0042] The test results are as follows:

[0043]

[0044]

Embodiment 3

[0046] Phosphoric acid 29, fumaric acid 6, citric acid 6, formate 15, propionate 15, benzoic acid 5, palm oil 10, white carbon black 14.

[0047] The preparation method is the same as in Example 1.

[0048] The test results are as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com