A kind of device and method for preparing water-based glass paint

A technology of water-based glass paint and transmission device, which is applied in the field of preparing underwater glass paint, can solve the problems of poor solvent resistance, weak permeability, poor adhesion, etc., achieves good stirring effect, accelerates reaction speed, and avoids material waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

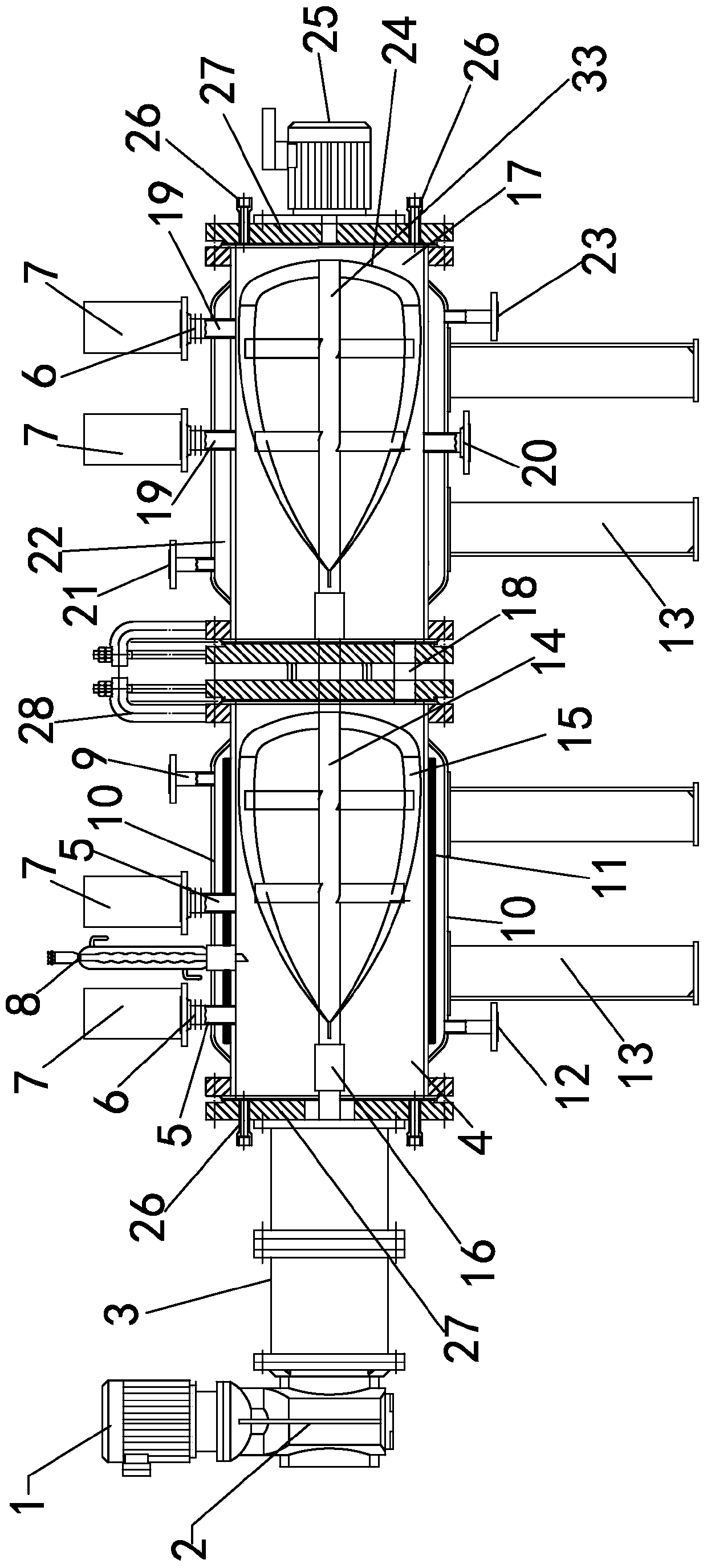

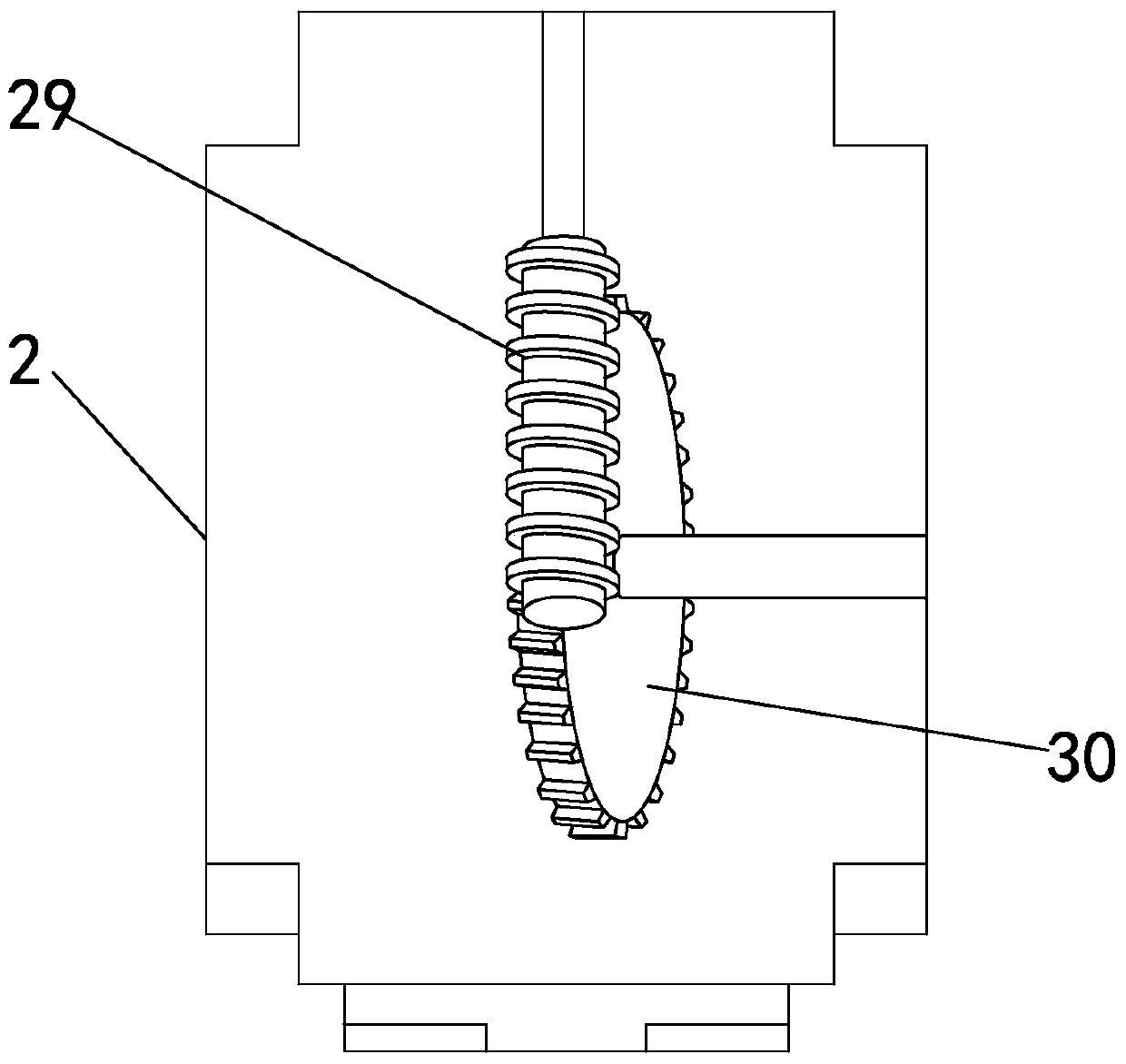

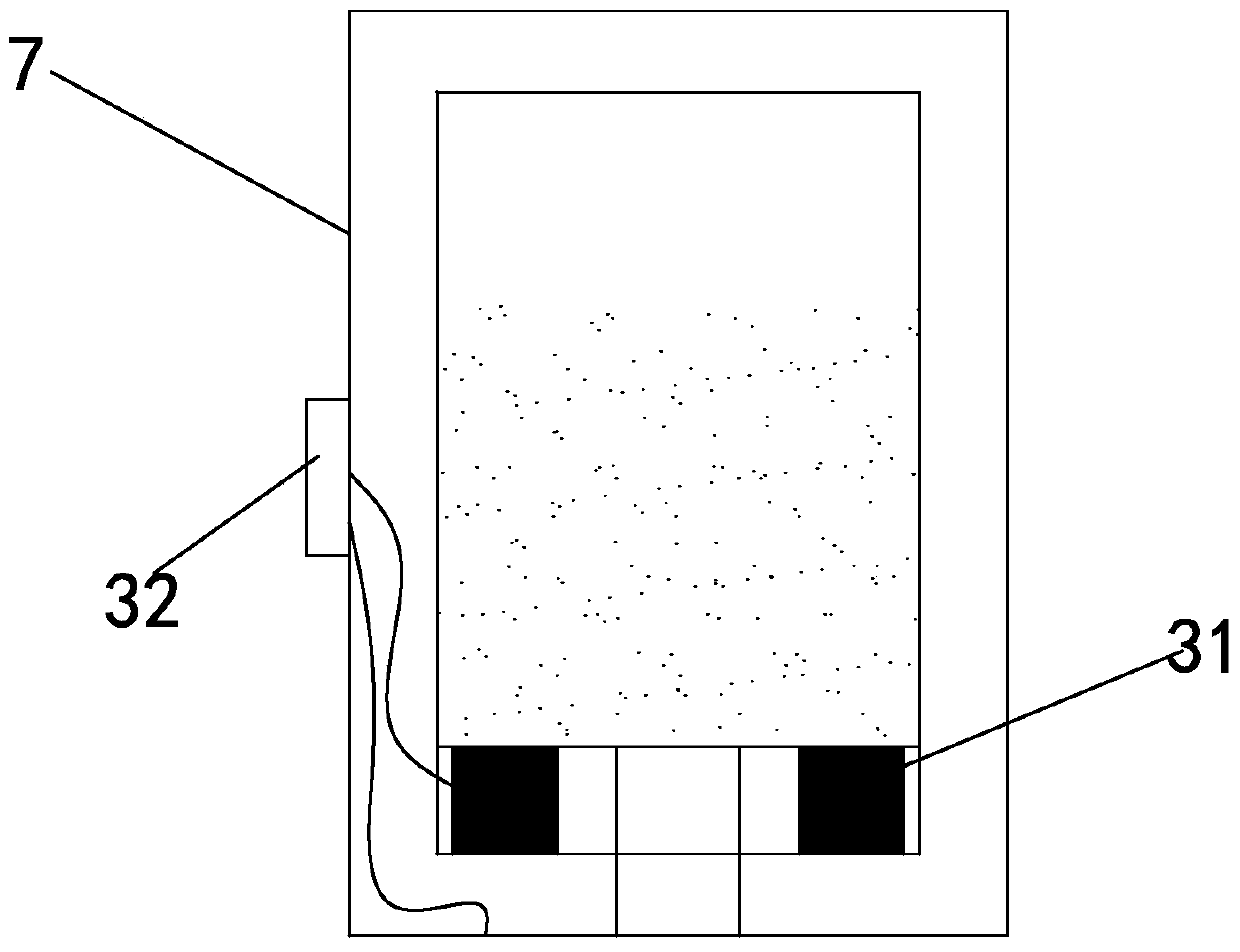

[0042] Such as Figure 1 to Figure 4 As shown, a device for preparing water-based glass paint includes a motor 1 and a reactor. The motor 1 is connected with a reducer 2. The output speed of the motor 1 is too fast. After being decelerated by the reducer 2, it can be converted into an appropriate speed output . A worm wheel 30 and a worm screw 29 are installed in the speed reducer 2 , the worm screw 29 is connected to the motor 1 , the worm screw 29 is connected to the worm wheel 30 , and the worm screw 29 and the worm wheel 30 are chelated with each other. When the motor 1 works, it drives the worm 29 to rotate, and the worm gear 30 and the worm 29 engage with each other through the gear teeth on its surface. Appropriate speed is formed after deceleration. The worm gear 30 is connected to the transmission device 3 , and the other end of the transmission device 3 is connected to the reactor, which includes the first reactor 4 and the second reactor 17 . The first reactor 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com