A kind of halloysite/rare earth perovskite composite SCR catalyst and preparation method thereof

A technology of SCR catalyst and rare earth calcium, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems that restrict the industrial application and promotion of catalysts, there is no high-efficiency SCR catalyst, and affect the denitrification effect. Activity, increased lattice defects, good gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

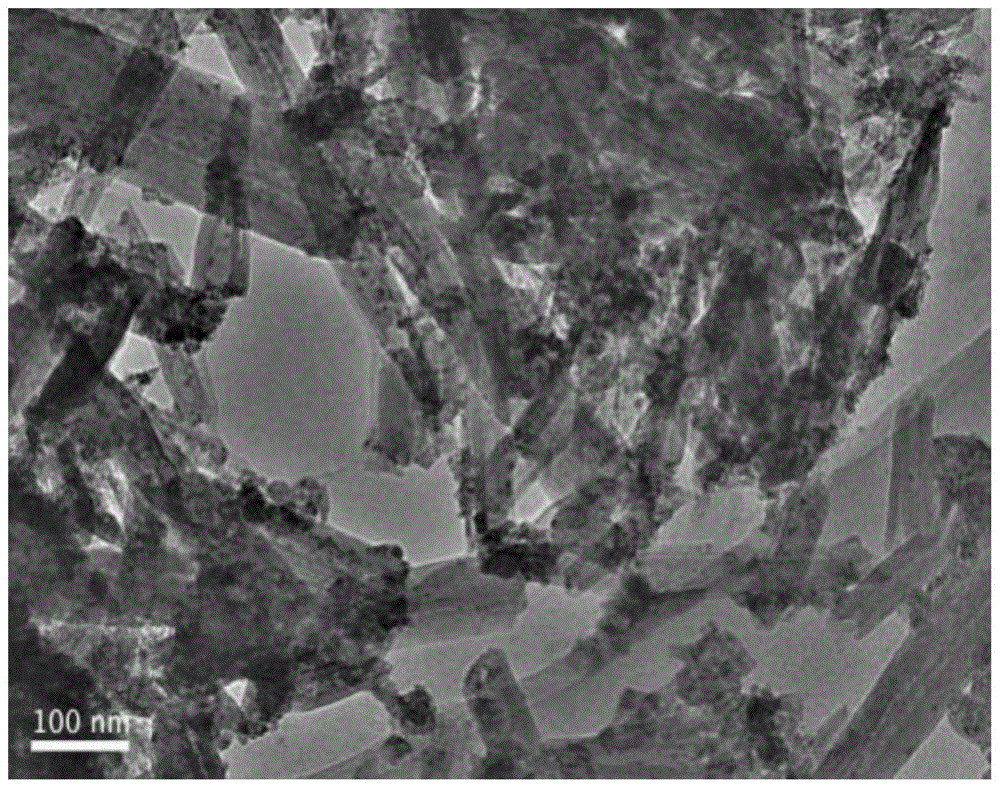

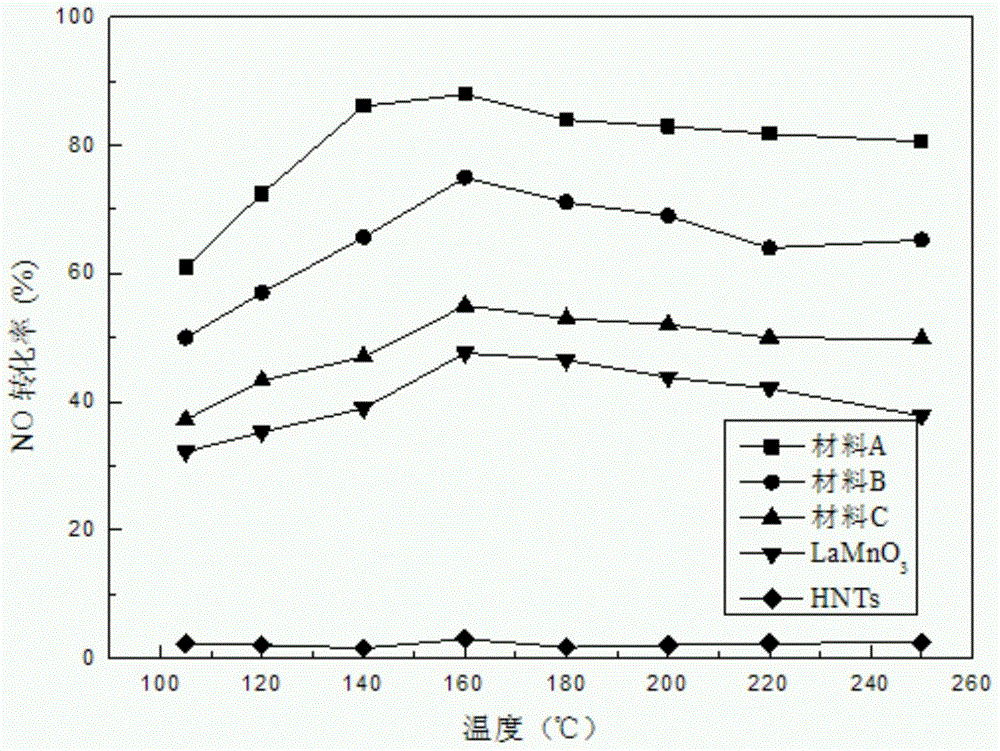

[0027] (1). Take 20g halloysite, dissolve it in 100mL deionized water, make the concentration of halloysite suspension be 10g / L, ultrasonic several minutes, add 2.69gLa(NO 3 ) 3 ·6H 2 O, 2.96g50%Mn(NO 3 ) 2 The solution was stirred and dissolved, and 3.48 g of citric acid was added into the mixed solution under continuous stirring, and 3 ml of dispersant ethylene glycol was added dropwise. It was placed in a water bath at a constant temperature of 80°C and reacted for 12 hours. Calcined at 550°C for 2 hours, granulated, passed through a 40-60 mesh sieve, and dried to obtain 10% LaMnO 3 / HNTs composite material, denoted as Material A. The X-ray powder diffraction experiment was carried out on the obtained sample, and its morphology and structure were observed under a transmission electron microscope.

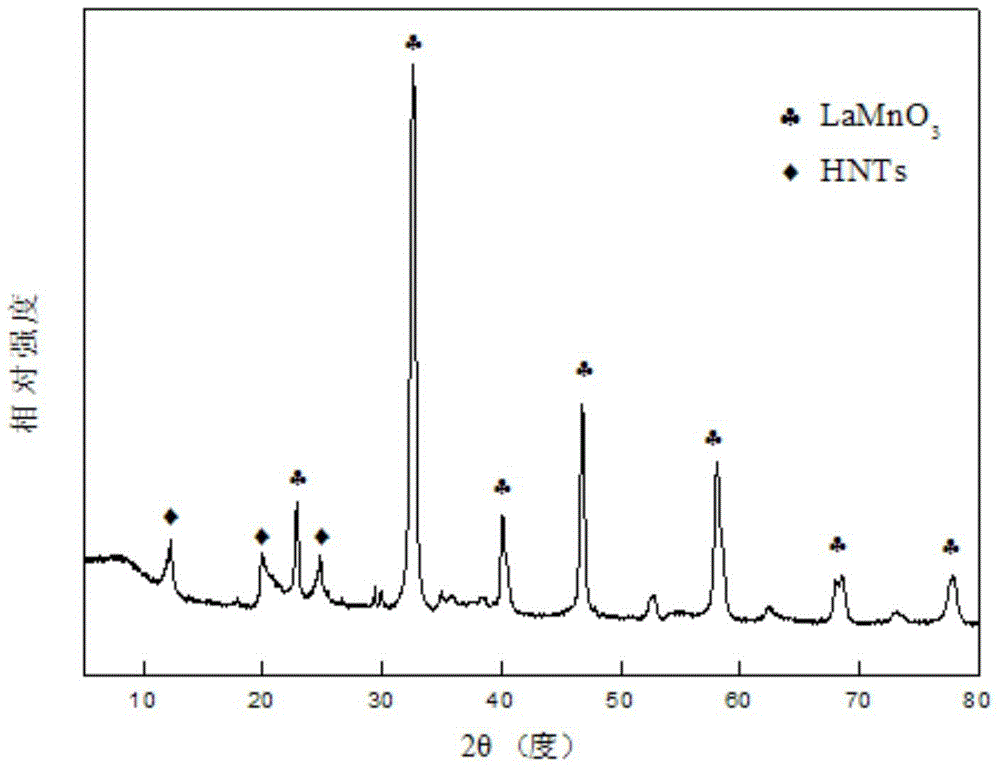

[0028] The LaMnO that prepares by embodiment 1 process method 3 / HNTs composite XRD such as figure 1 shown. It can be seen from the figure that the composite material ma...

Embodiment 2

[0033] Change La(NO 3 ) 3 ·6H 2 The amount of O is 1.35g, 50% Mn(NO 3 ) 2 The amount is 1.04g, the concentration of halloysite is 20g / L, weigh 5g sodium tripolyphosphate, 10ml dispersant methyl pentanol, put it in a water bath, keep the temperature at 60°C, stir for 18h, and calcined at 450°C 3h, granulate, pass through a 40-60 mesh sieve, and dry to obtain 5% LaMnO 3 / HNTs.

[0034] The follow-up SCR denitrification test was as in Example 1, and the results showed that at 160°C, the nitrogen oxide removal rate of the composite material prepared in Example 2 reached 82%.

Embodiment 3

[0036] Change La(NO 3 ) 3 ·6H 2 The amount of O is 1.35g, 50% Mn(NO 3 ) 2 The amount is 1.04g, the concentration of halloysite is 10g / L, 5g of citric acid and 7ml of dispersant methyl pentanol are weighed, placed in a water bath, kept at a constant temperature of 60°C, stirred for 18h, and calcined at 450°C for 3h. Granulate, pass through a 40-60 mesh sieve, and dry to obtain 20% LaMnO 3 / HNTs.

[0037] The follow-up SCR denitration test is as in Example 1. The results show that at 160°C, the nitrogen oxide removal rate of the composite material in Example 3 reaches 78%, and the effect is slightly lower than that of the materials in Example 1 and Example 2. It may be Partial agglomeration occurred after the loading increased, which affected the catalytic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com