An underwater welding training device and its use method

A technology for underwater welding and welding power source, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting time and high cost, and achieve the effect of simple operation method, low cost and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

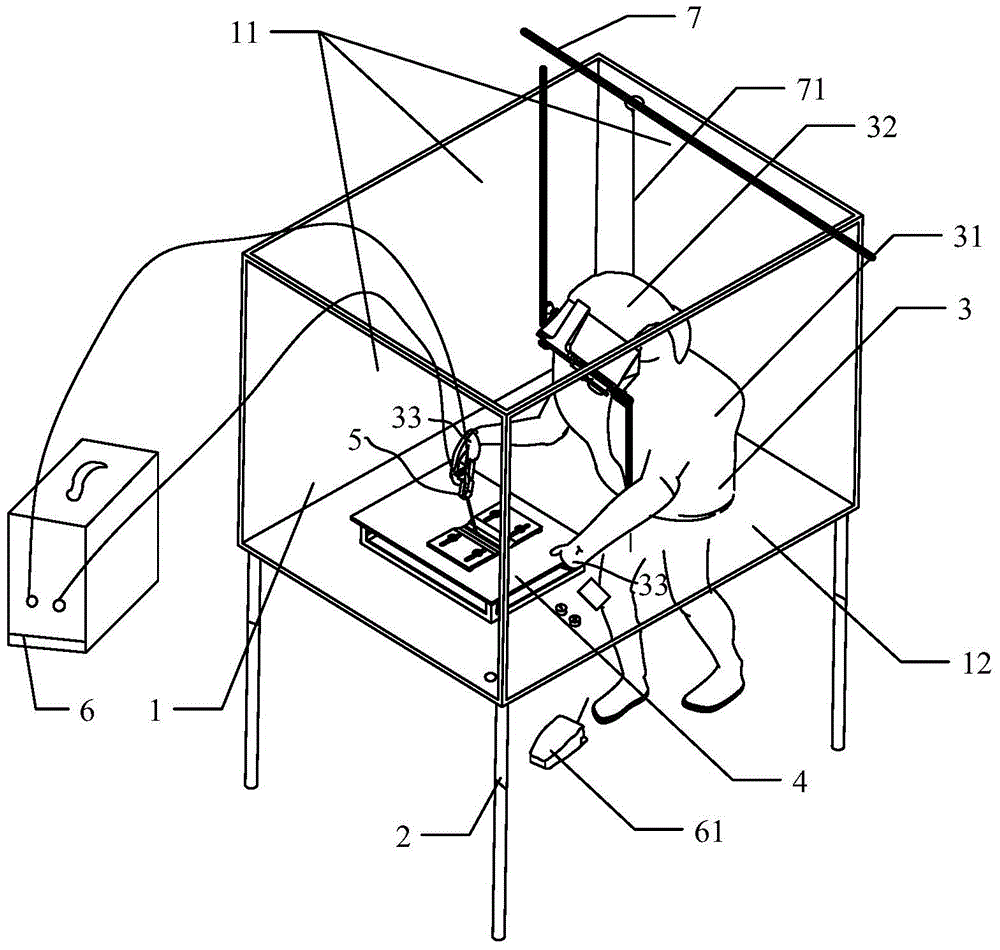

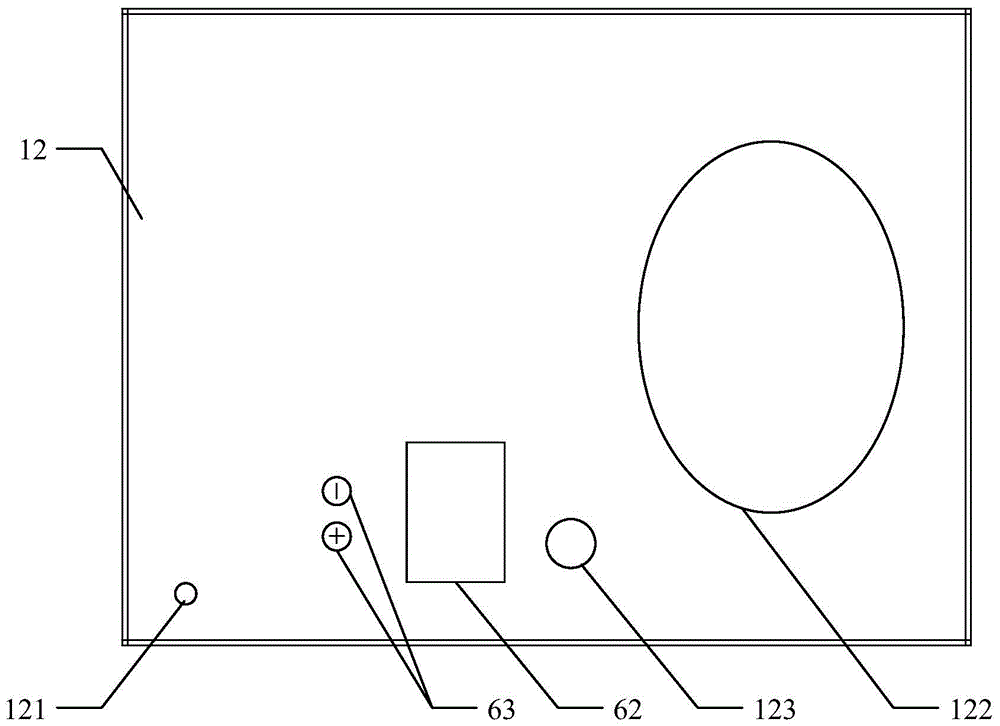

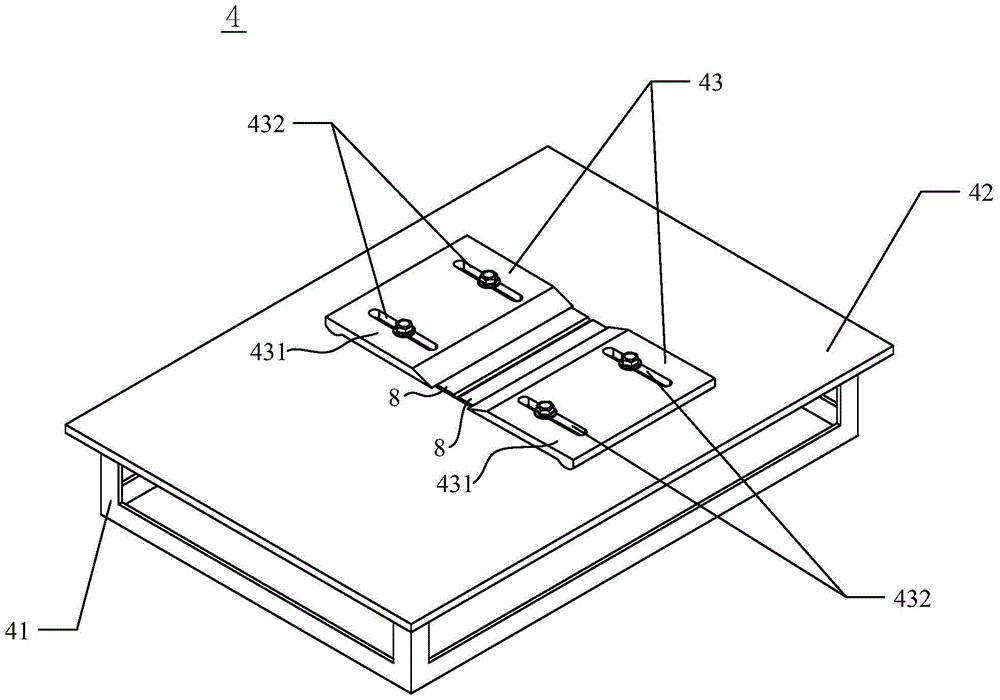

[0024] Such as figure 1 As shown, the underwater welding training device provided by the present invention includes a transparent water tank 1, a support 2, a diving suit 3, a welding workbench 4, an underwater wet welding torch 5, a welding power supply 6 and an air circulation device (not shown in the figure) Out), the transparent water tank 1 includes a side plate 11 and a bottom plate 12, and the joints between the side plates 11 and the side plate 11 and the bottom plate 12 are sealed, such as figure 2 As shown, the bottom plate 12 is provided with a drainage hole 121, a through hole 122 and a ventilation hole 123, and the drainage hole 121 can be opened or clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com