Dual-interface card production method and device

A dual interface card and production method technology, applied in the field of mobile communication, can solve the problems of waste of raw materials, low yield, low production efficiency, etc., and achieve the effects of reducing production cost, high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

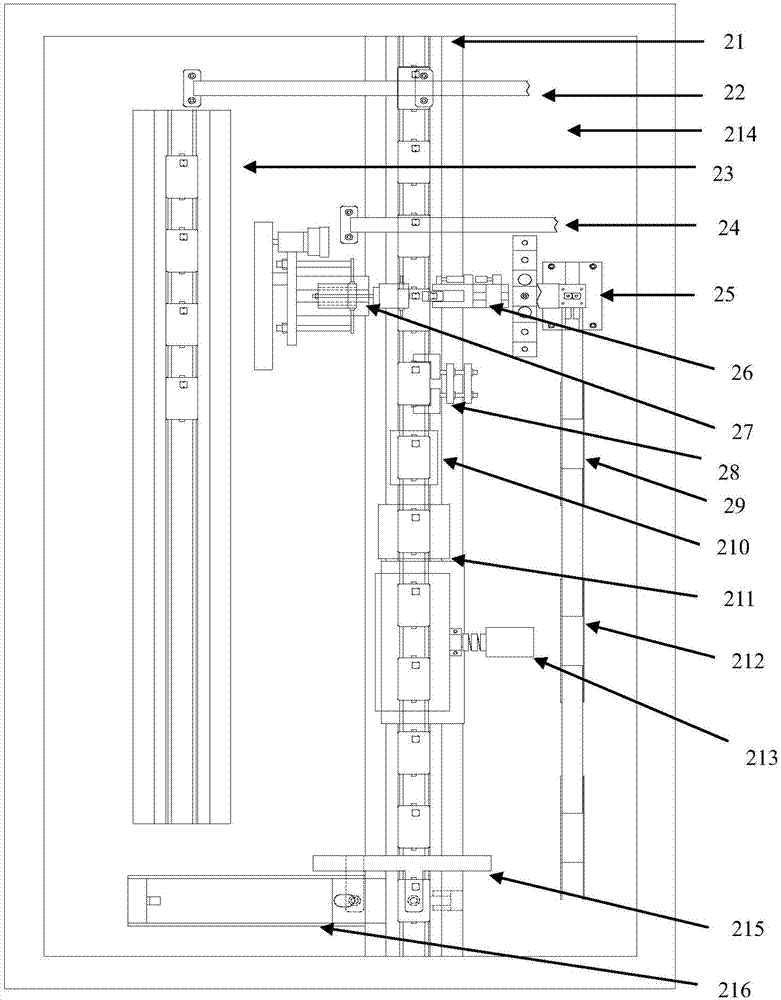

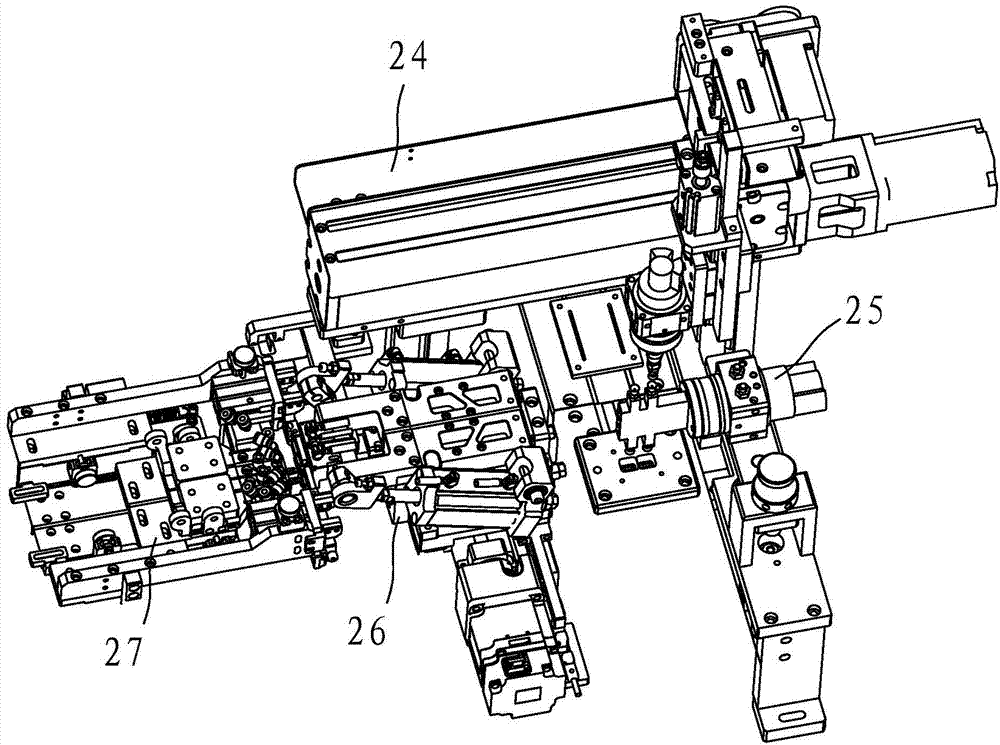

[0047] In order to solve the defects of low welding efficiency and low production capacity of dual-interface cards in the prior art, the present invention provides a production method and equipment for dual-interface cards with high welding efficiency and high production capacity.

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

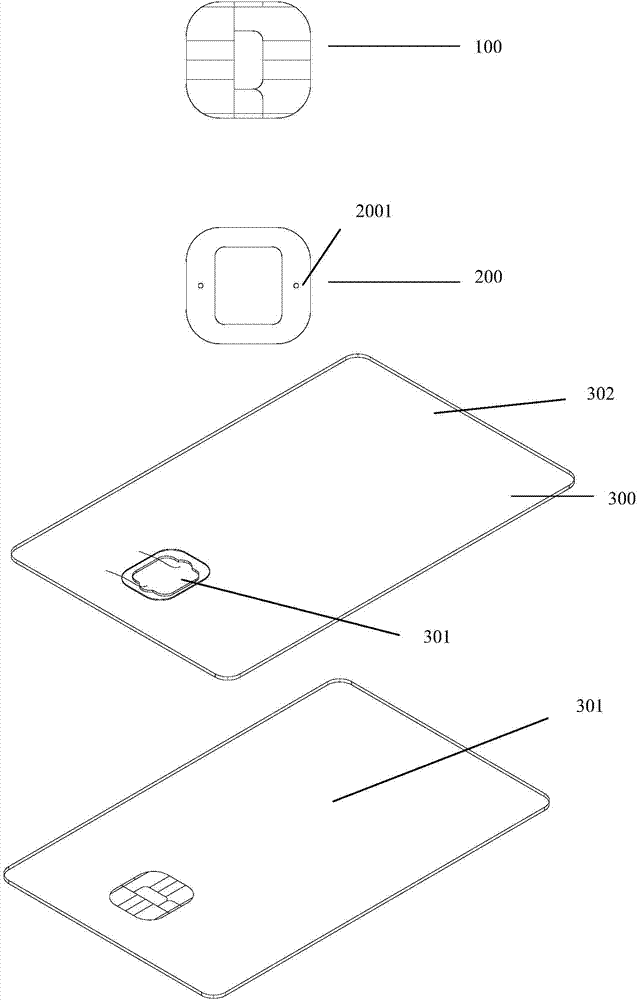

[0049] figure 1 It is a schematic diagram of the manual production process of the dual-interface card in the prior art; the chip 301 on the dual-interface card includes a front side 100 and a back side 200, and the back side 200 has predetermined solder joints 2001. In the prior art, the chip 301 is manually welded to the card base 302 with the antenna to obtain the dual interface card 300 with the antenna card base, and the dual interface car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com