Disassembling and assembling tool of isolating valve body sealing assembly and overhaul disassembling and assembling process

A technology for sealing components and disassembly tools, which is applied in the manufacture of tools, hand-held tools, etc., can solve the problems that hidden dangers cannot be completely eliminated, the value of the valve body 61 is high, and it is difficult to guarantee the angle, so that the disassembly process is convenient, reliable, and guaranteed Consistency of assembly and improvement of assembly and disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

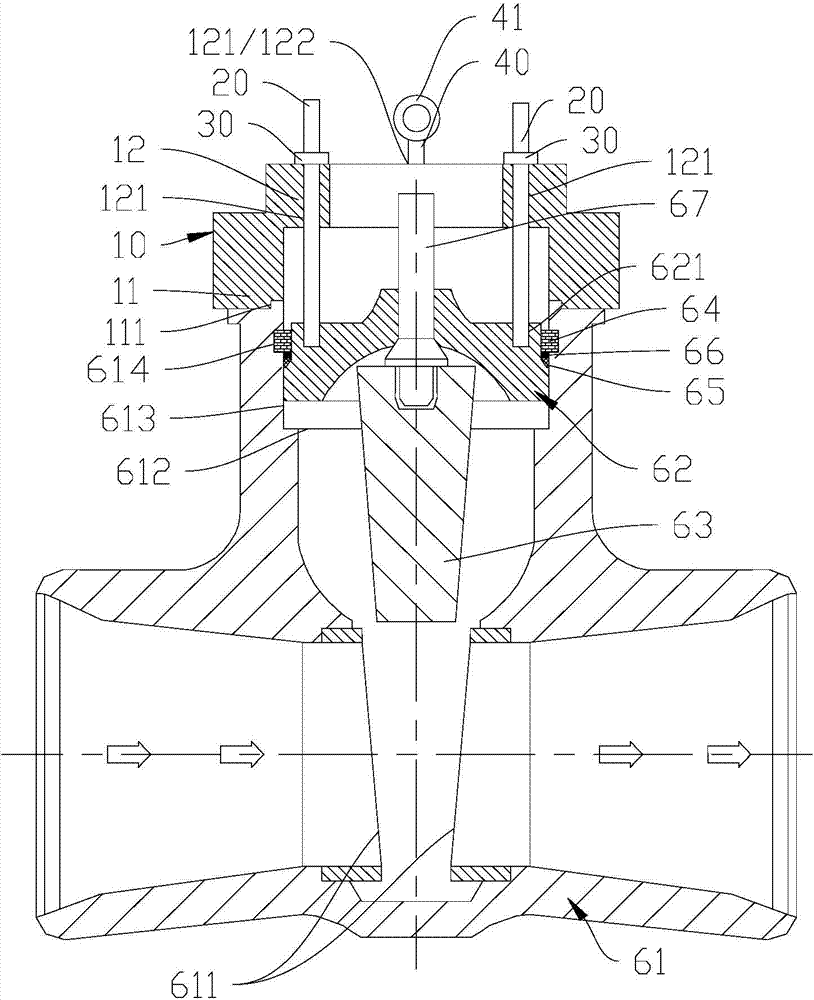

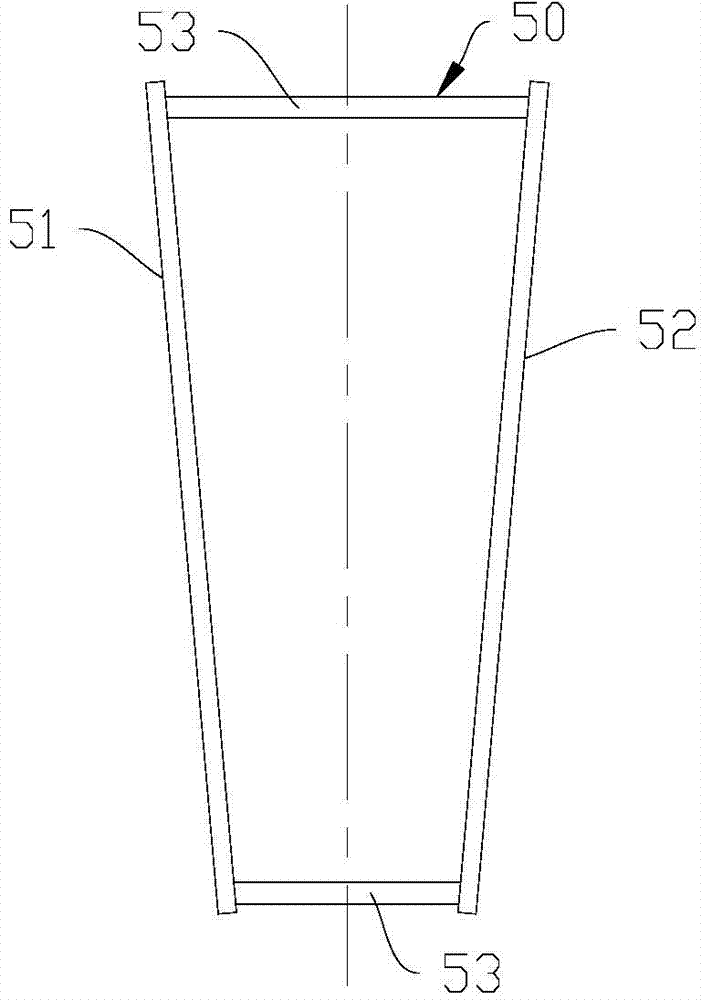

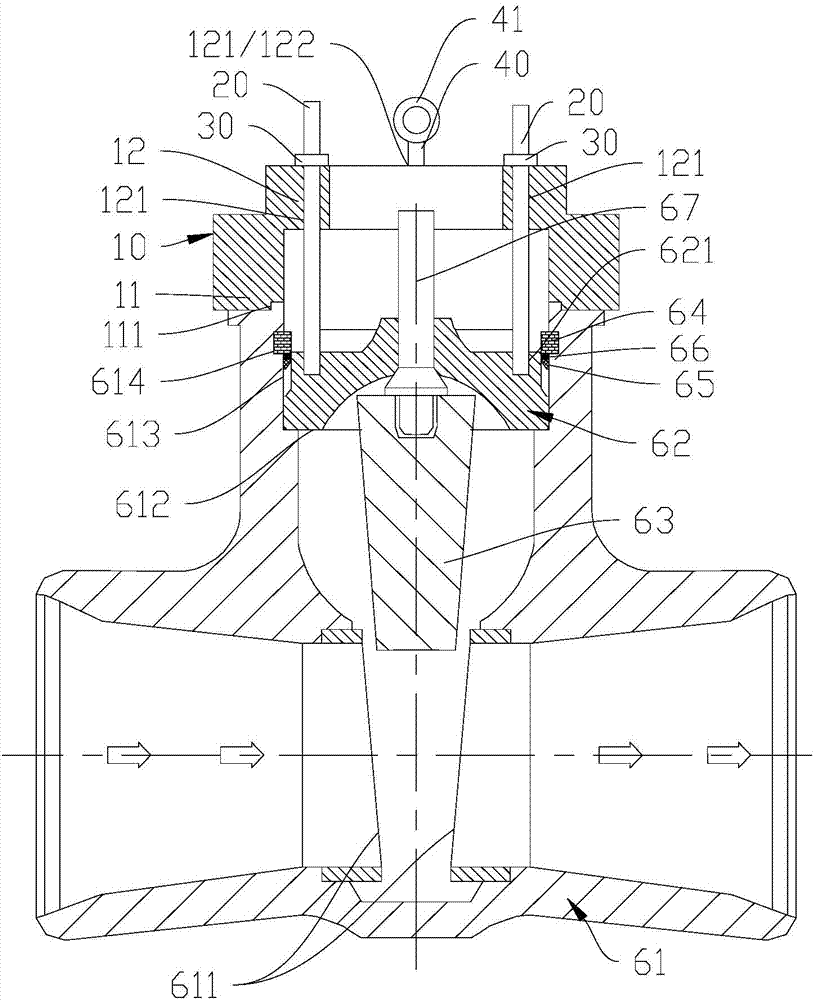

[0041] Such as figure 1 and figure 2 As shown, the assembly and disassembly tool of the valve body sealing assembly of the isolation valve in a preferred embodiment of the present invention includes a support 10 for placing on the valve body 61, on which there are several parts distributed on the valve cover 62 At least three second connecting holes 121 corresponding to the first connecting holes 621 ; at least three lifting screw rods 20 adapted to the at least three second connecting holes 121 and fastening nuts 30 disposed on the lifting screw rods 20 . After the lifting screw 20 passes through the second connecting hole 121 , it is fitly connected with the first connecting hole 621 . In this embodiment, by unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com