Artificial board cold pressing and formation and unloading circulation equipment

A recycling equipment, wood-based panel technology, used in auxiliary molding equipment, ceramic molding machines, ceramic molding workshops and other directions, can solve the problems of poor product strength, low production efficiency, low density, etc., to achieve fast loading and unloading action, improve efficiency and density. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

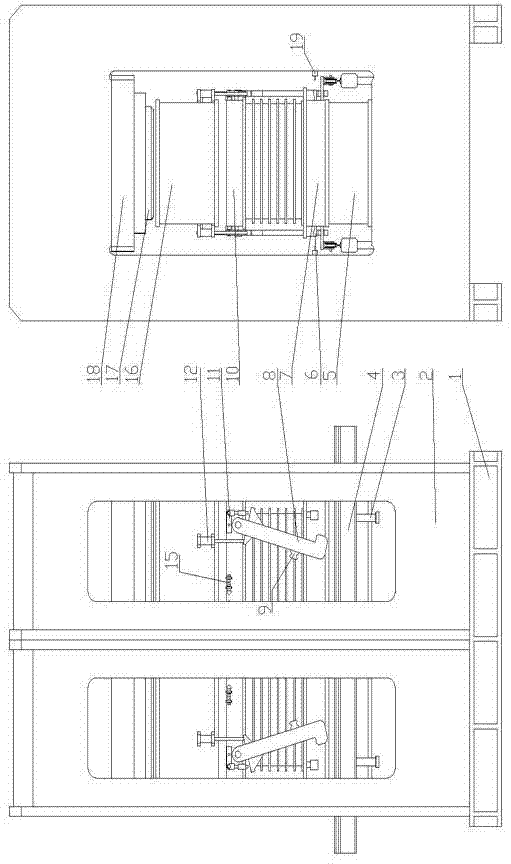

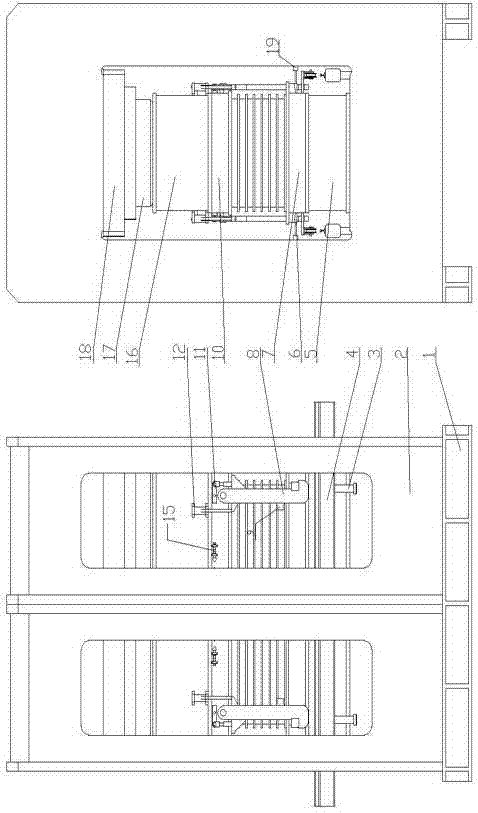

[0038] Such as figure 1 As shown in -12, the slab cold press, drying tunnel kiln, and pressure unloading machine are installed in series and circularly arranged through the guide rails of the circulating pressure holding car, and the circulating pressure holding car circulates in the slab cold press through the guide rails of the circulating pressure holding car , drying tunnel kiln, and unloading machine; a slab loading unit is set in front of the slab cold press, which is composed of a paving machine, a metal pallet and a slab-feeding grabbing mechanism; a slab unloading unit is set behind the unloading machine, consisting of The grabbing mechanism of the upper beam (10) of the circulating pressure holding vehicle, the sucker device for unloading the dried slabs and metal pallets in layers, the separation and distribution mechanism of the dried slabs and metal pallets, various devices and mechanisms Contact as follows:

[0039] The board loading unit device is composed of ...

Embodiment 2

[0047] As in Example 1, the number of stacks is set to be 40 layers, and the length of the locking arm (8) of the cycle pressure holding vehicle is adapted to the number of slab layers stacked in 40 layers, that is, the 40 layers after compaction. The total height of the ply layers is suitable.

Embodiment 3

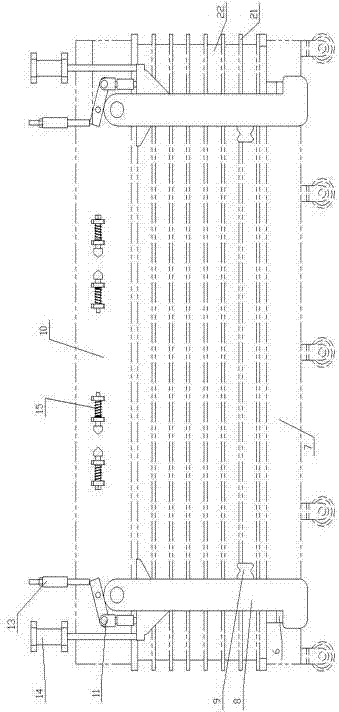

[0049] Such as Figure 4 , 6 , 7, 8, 11, and 12, manufacture and install a cycle pressure-holding vehicle matched with the circulation equipment of cold press, forming, and pressure relief machine, the upper beam (10) and belt wheels (29) The lower beam (7) of the circulating pressure maintaining vehicle is composed of the lower beam (7) of the circulation pressure maintaining vehicle; the front and rear sides of the upper beam (10) of the circulating pressure maintaining vehicle are symmetrically arranged with the positioning link (11) and the lock buckle with the block (9) sequentially on the center line The arm (8) and the embedded positioning lock (15); the two ends of the lower beam (7) of the circulating pressure holding vehicle are symmetrically designed and installed with the lower beam stator (20) and the oblique pin (6); the composition and connection of each component are as follows :

[0050] a. There are 4 positioning links (11), which correspond to the socket (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com