Preparation of Alkylphenol Polyoxyethylene Ether Phosphate Formaldehyde Polycondensation Surfactant

A technology of alkylphenol polyoxyethylene ether and surfactant, which is applied in the field of alkylphenol polyoxyethylene ether phosphate, can solve the problems of complex reaction process of dispersant, low utilization rate of raw materials, large investment in equipment, etc., and achieves Good dispersion effect, promotion of homogeneous phase formation, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

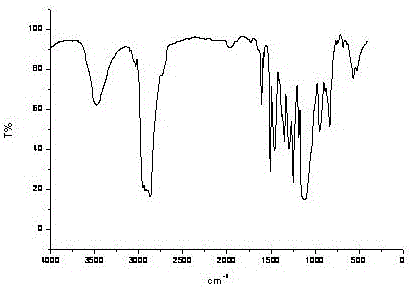

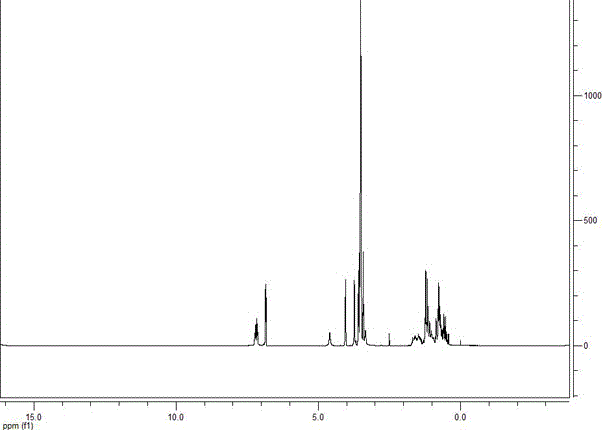

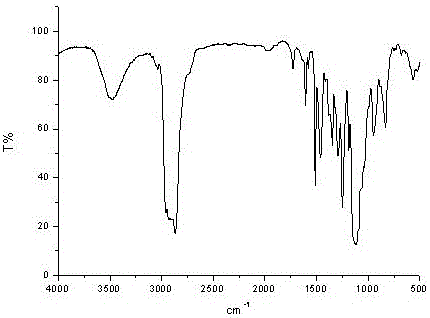

Image

Examples

Embodiment 1

[0059] 1) Synthesis of p-nonylphenol polyoxyethylene ether dimerization and trimerization surfactant (n=1, m=4)

[0060] 4-p-Cresol and the solid sodium hydroxide whose mass percentage is 3% calculated from the monomer were added to the autoclave, evacuated to 0.05Mpa, and after repeated replacement with nitrogen gas for 3 times, according to the addition of the EO group. The number of moles m=4 was introduced, 4 mol of ethylene oxide was heated to 100 ° C under stirring, the pressure was maintained at 1 Mpa, the reaction was performed for 1 h, the reaction was stopped and cooled to room temperature, and the product was taken out from the autoclave to obtain nonyl Phenolic polyoxyethylene ether surfactant, yield 98%.

[0061] The molar ratio of p-nonylphenol polyoxyethylene ether and formaldehyde is the ratio of p-methylphenol polyoxyethylene ether:formaldehyde=2:1 into the reactor with nitrogen protection device, start stirring, add monomer to calculate Sulfuric acid with a ...

Embodiment 37

[0079] The critical micelle concentration of surfactant solution was determined by surface tension method. Comparison of critical micelle concentration (CMC) values of polysurfactant (NP2-9) and nonylphenol polyoxyethylene ether monomolecular surfactant (NP-9)

[0080] Sample cmc(mmol / L) γcmc (mN / m) NP-9 0.68 30.3 NP2-9 0.075 29.8 NP3-9 0.053 28.7

[0081] It can be seen from the above table that the CMC value of NP3-9 and NP2-9 is one order of magnitude lower than that of NP-9, and the CMC value of NP3-9 is also 20% smaller than that of NP2-9, and the surface properties are significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com