A preparation method of flexible and highly conductive three-dimensional interconnected hollow carbon fibers

A technology of high conductivity and hollow carbon, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problem of low loading capacity and achieve the effect of simple operation, good conductivity and high capacity adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

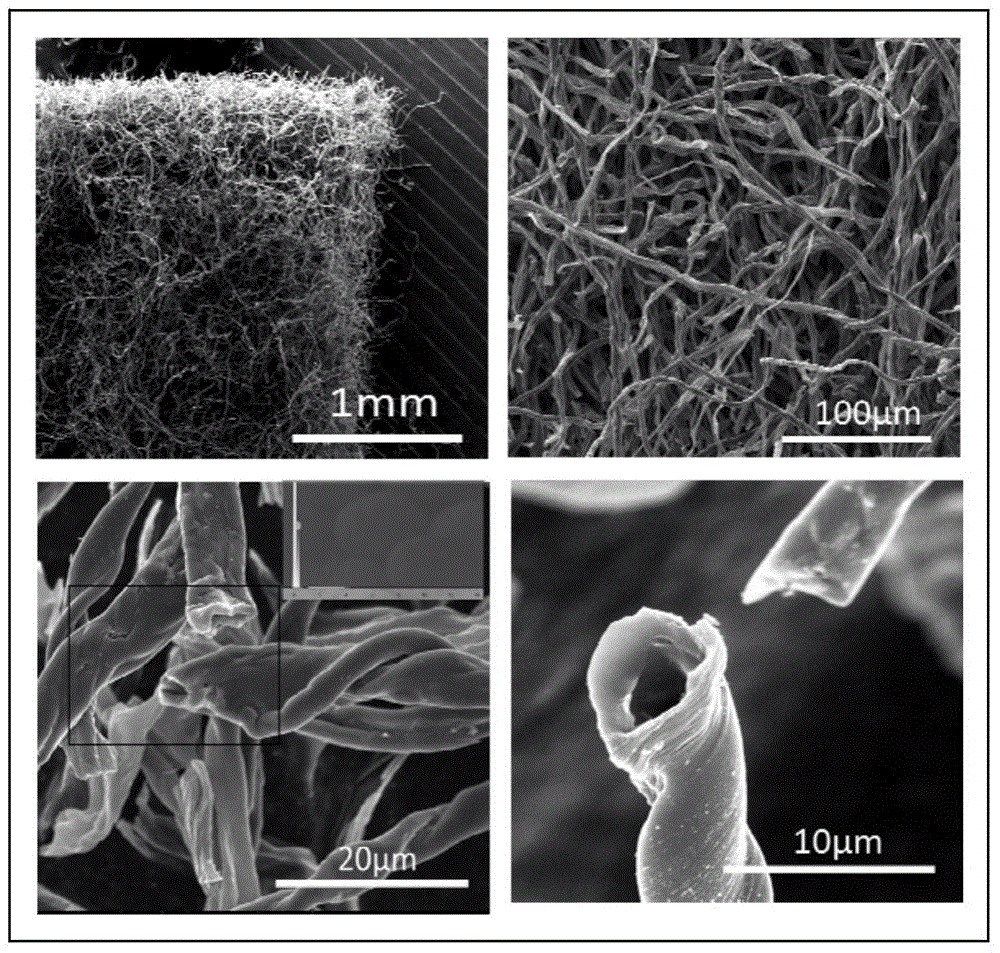

[0039] In a specific embodiment, the method for preparing flexible and highly conductive three-dimensional interconnected hollow carbon fibers of the present invention uses long-fiber cellulose filaments as raw materials, and carbonizes and crystallizes the material through high-temperature treatment, thereby obtaining volume-controllable, hollow, highly conductive, and flexible carbon fibers. Carbon fiber network structure, the hollow carbon fiber has a diameter of 1-100 microns and an inner diameter of 0.5-90 microns. The specific steps are as follows:

[0040] (1) Select a certain amount of long-fiber filamentous raw materials (medical absorbent cotton, high-purity cosmetic cotton, absorbent cloth, natural cotton, cotton cloth and other carbon-containing long-fiber materials), and immerse them in carbonates (ammonia bicarbonate, sodium bicarbonate, Sodium carbonate, ammonium carbonate or magnesium carbonate, etc.) solution, add hydrochloric acid, nitric acid, acetic acid or ...

Embodiment 1

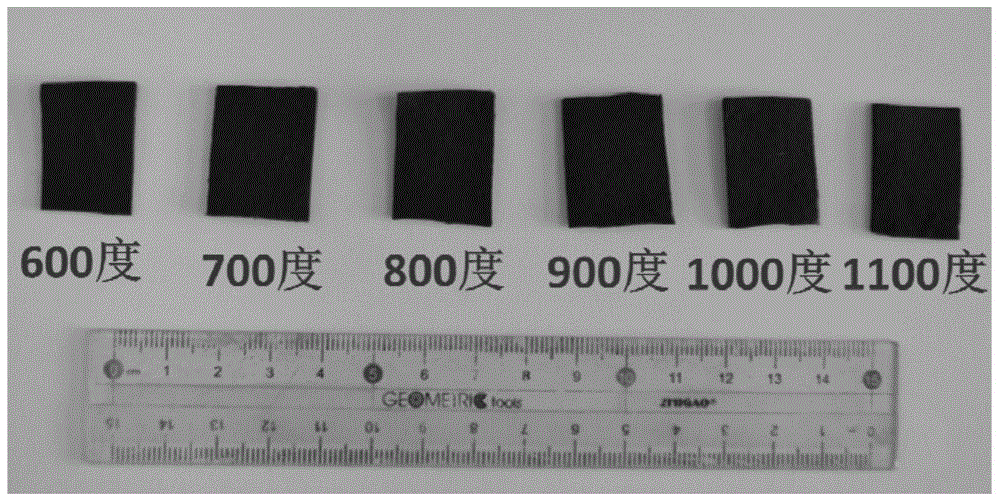

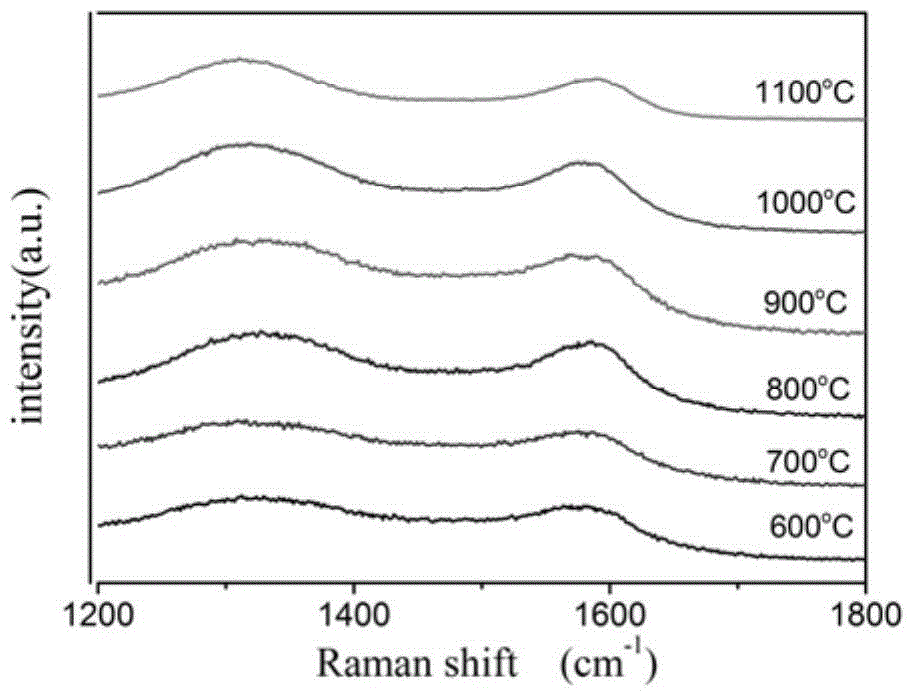

[0047] Process the cleaned and dried absorbent cotton into a mold of 2 cm × 3 cm × 2 mm, put it into a horizontal furnace, vacuumize, use argon as a protective gas (flow rate is 1000 sccm), and heat at 10 °C / min. The heating rate was raised to 600 °C, the heat treatment time was 4 h under argon, and the temperature was lowered to room temperature. Take out samples such asfigure 1 , image 3 shows poor crystallinity, Image 6 The sample resistance was shown to be 1.6M ohms. The sample resistance test uses a multimeter, and the measuring distance between the two probes is 1 cm.

Embodiment 2

[0049] Process the cleaned and dried absorbent cotton into a mold of 2 cm × 3 cm × 2 mm, put it into a horizontal furnace, vacuumize, use argon as a protective gas (flow rate is 1000 sccm), and heat at 10 °C / min. The heating rate was raised to 700 °C, the heat treatment time was 4 h under argon, and the temperature was lowered to room temperature. Take out samples such as figure 1 , image 3 shows poor crystallinity, Image 6 The sample resistance was shown to be 1.3K ohms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com