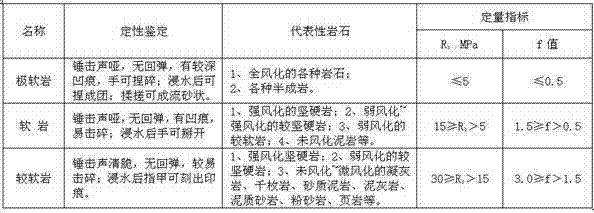

Smooth blasting method applied to soft rock and extremely soft rock

A technology of smooth blasting and extremely soft rock, which is applied in the field of smooth blasting, smooth blasting of soft rock and extremely soft rock. The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

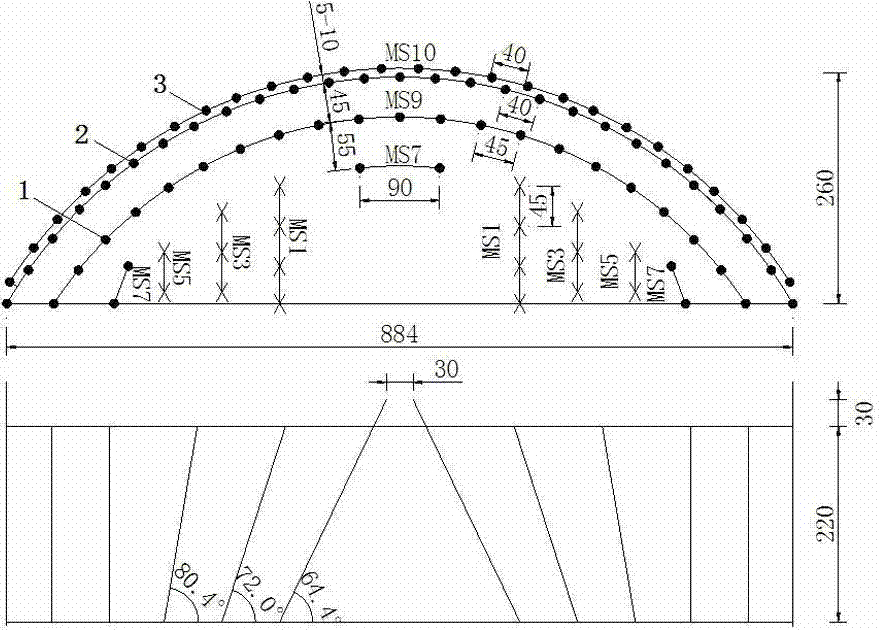

[0033] A smooth surface blasting method applied to soft rock and extremely soft rock according to the present invention includes drilling and charging on the working surface, and the blasting process:

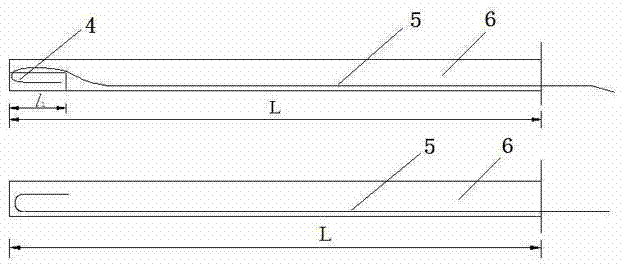

[0034] The perforation specifically includes: defining a photoblast layer along the top boundary of the working surface, and the photoblast layer is composed of a peripheral photoblast hole column located on the outer side closer to the top boundary and an outer ring caving hole row adjacent to the peripheral photoblast hole row. The rock mass composition, the outer side of the peripheral light blasting hole row also has a treatment undercut short hole row, and the processing undercut short hole in the treatment undercut short hole row is interlaced with the peripheral photoblasting holes in the peripheral photoblast hole row Distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com