High-temperature blast hole cooling method

A high-temperature blast hole and blast hole technology, which is applied in the field of high temperature blast hole cooling, can solve the problems of wasting water resources, high potential safety hazards, restricting the progress of blasting operations in high temperature fire areas, etc. Effect of gas channeling and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

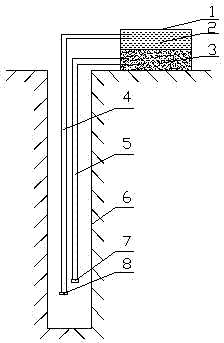

[0022] Embodiment 1: a kind of high-temperature blast hole cooling method, such as figure 1 shown, including the following steps:

[0023] (1) Water 1 and cement slurry 3 are respectively injected into the two boxes of the jetting machine 1. The jetting machine 1 is an ordinary concrete jetting machine commonly used in the construction field. The water spray spray bar 4 and the spray spray bar 5 are scalable spray bars, and the water spray spray bar 4 and the spray spray bar 5 are L-shaped, and its free end, that is, the shaft extending in the vertical direction can be telescopic, and the shaft of the shaft The lower end is respectively provided with a water spray nozzle 8 and a spray nozzle 7. The nozzle can descend and rise in the blast hole 6 along with the expansion and contraction of the shaft. The water nozzle 8 and the spray nozzle 7 are respectively provided with horizontally oriented nozzles. The nozzle can spray liquid 360° horizontally, and the spray nozzle 7 is al...

Embodiment 2

[0029] Embodiment 2: In this embodiment, the cooling method is basically the same as in Embodiment 1, except that the high-temperature-resistant and anti-gas channeling latex cement slurry poured in the jet machine 1 is made of 88-90 wt.% ordinary cement slurry It is prepared by mixing with 12-10wt.% high-temperature anti-channeling latex cement admixture. In step (4), when the spraying boom 5 rises, the spraying nozzle 7 stops spraying downwards, only for the blast hole 6 The hole wall is sprayed horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com