Drilling mud cake hardening enhancer

A technology of reinforcing agent and drilling mud, which is applied in the field of drilling fluid additives, and can solve the problems of poor sealing quality of bonding strength and cementing interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 9 g of sodium hydroxyethylidene diphosphate-sodium polyacrylate, 40 g of modified calcium magnesium silicate whiskers, 11 g of titanate coupling agent JTW-201, 18 g of hydrated silicon dioxide, and 12 g of polyether organic disilicate sodium 10g of polycarboxylic acid comb macromolecule MF-508 is mixed to make drilling mud cake hardening enhancer.

Embodiment 2

[0027] Weigh 12g of sodium hydroxyethylidene diphosphate-sodium polyacrylate, 37g of modified calcium magnesium silicate whiskers, 12g of titanate coupling agent JTW-201, 16g of hydrated silicon dioxide, and 13g of polyether organic disilicate sodium 10g of polycarboxylic acid comb macromolecule MF-508 is mixed to make drilling mud cake hardening enhancer.

Embodiment 3

[0029] Weigh 8 g of sodium hydroxyethylidene diphosphate-sodium polyacrylate, 41 g of modified calcium magnesium silicate whiskers, 9 g of titanate coupling agent JTW-201, 17 g of hydrated silicon dioxide, and 13 g of polyether organic disilicate sodium 12g of polycarboxylate comb macromolecule MF-508 is mixed to make drilling mud cake hardening enhancer.

[0030] The components used in the examples are all commercially available. The manufacturer of the titanate coupling agent JTW-201 is Nanjing Pinning Coupling Agent Co., Ltd., and the manufacturer of the polycarboxylate comb-like macromolecule MF-508 is Qinhuangdao Concrete Construction Admixture Co., Ltd.

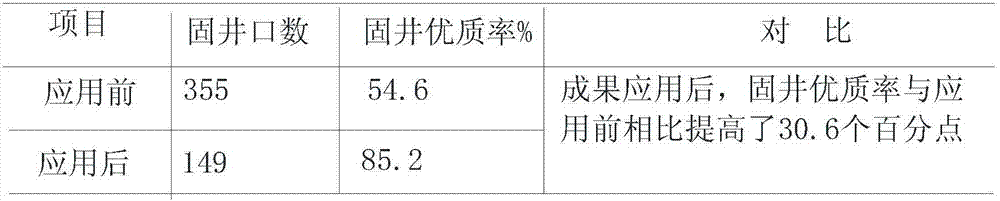

[0031] The hardening enhancer prepared in the above-mentioned embodiment is added to the drilling fluid according to the ratio of 1.5-3% by weight and volume after drilling and passing through the well as required, and the performance of the drilling fluid is controlled to meet the requirements of drilling engineering a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com