Cement slurry for plugging and anti-gas channeling for cementing of small hole easily lost or narrow gap annular well

A narrow gap, anti-gas channeling technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting the production life of oil and gas wells, prone to leakage, and unable to meet the sealing capacity, etc., to achieve comprehensive engineering performance Well-coordinated, strong plugging, leak-proof, and gas-channeling capabilities, and well-coordinated comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

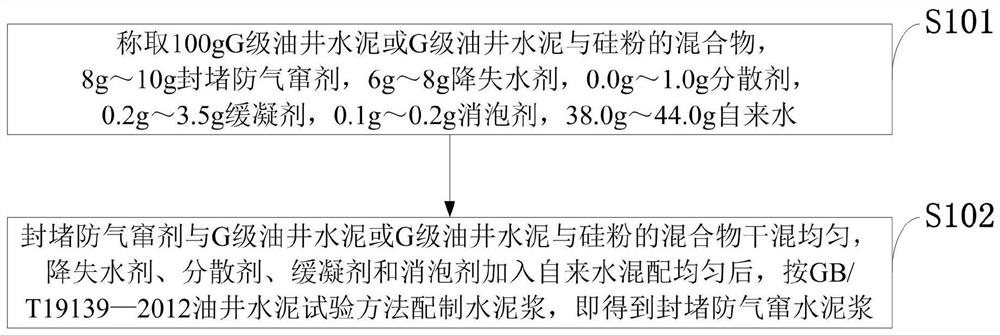

[0034] Embodiment 1: Preparation and performance of cement slurry adapted to bottom-hole static temperature of 90°C (circulation temperature of 81°C):

[0035] Weigh 600 grams of G grade oil well cement, 48 grams of plugging and anti-air channeling agent, 36 grams of fluid loss reducer, 0.4 grams of dispersant, 3.6 grams of retarder, 0.6 grams of defoamer, and 228 grams of tap water. The plugging and anti-channeling agent is dry-mixed with G-grade oil well cement evenly, and the fluid loss reducer, dispersant, retarder and defoamer are added into tap water and mixed evenly, and then prepared according to the test method of GB / T 19139-2012 oil well cement Cement slurry, that is, to obtain a density of 1.90g / cm 3 The plugging and anti-gas channeling cement slurry.

[0036] The cement slurry of the embodiment of the present invention has a plugging time of 8 seconds and a pressure of 5.7 MPa when the static temperature at the bottom of the well is 90°C and the circulation temper...

Embodiment 2

[0037] Embodiment 2: Preparation and performance of cement slurry adapted to bottom-hole static temperature of 180°C (circulation temperature of 153°C):

[0038] Weigh 600 grams of G grade oil well cement, 210 grams of silicon powder, 60 grams of plugging and anti-air channeling agent, 48 grams of fluid loss reducer, 0.2 grams of dispersant, 21 grams of retarder, 1.2 grams of defoamer, 264 grams of tap water . The plugging and anti-channeling agent is dry-mixed with G oil well cement and silica fume, and the fluid loss reducer, dispersant, retarder and defoamer are added to tap water and mixed evenly, according to GB / T 19139-2012 oil well cement test The method is to prepare cement slurry to obtain a density of 1.90g / cm 3 The plugging and anti-gas channeling cement slurry.

[0039] The cement slurry of the embodiment of the present invention is used when the static temperature at the bottom of the well is 180°C and the circulation temperature is 153°C. The measured plugging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com