Thin and long part assembling method

An assembly method and technology for long parts, applied in the field of parts positioning, can solve the problems of long cycle, poor rigidity, and difficulty in ensuring assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

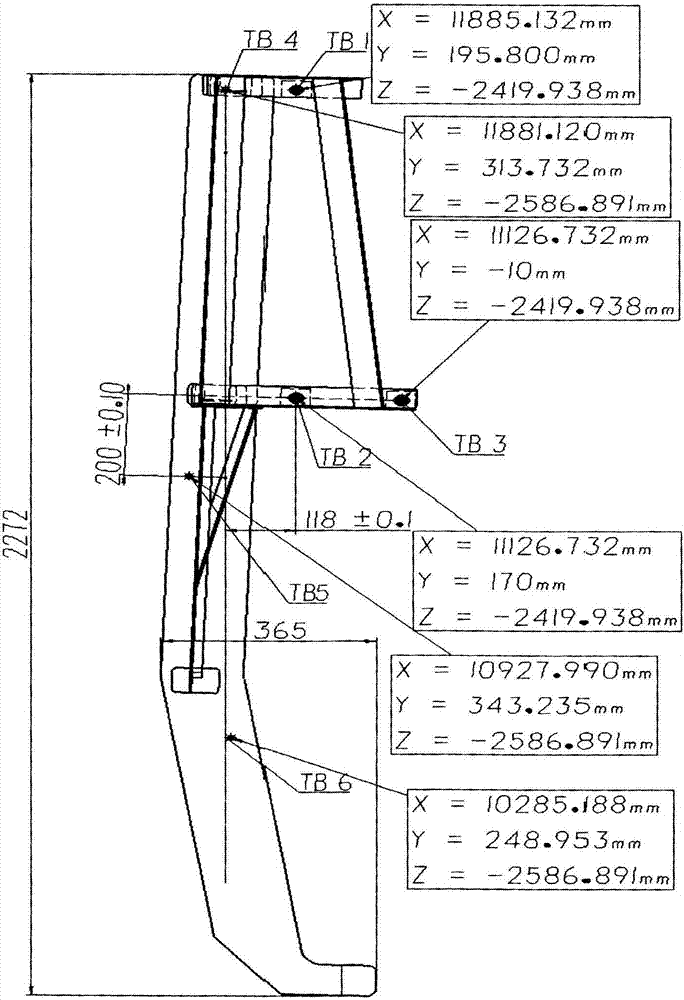

[0016] Such as image 3 As shown, an assembly method of thin, thin and long parts includes the following steps:

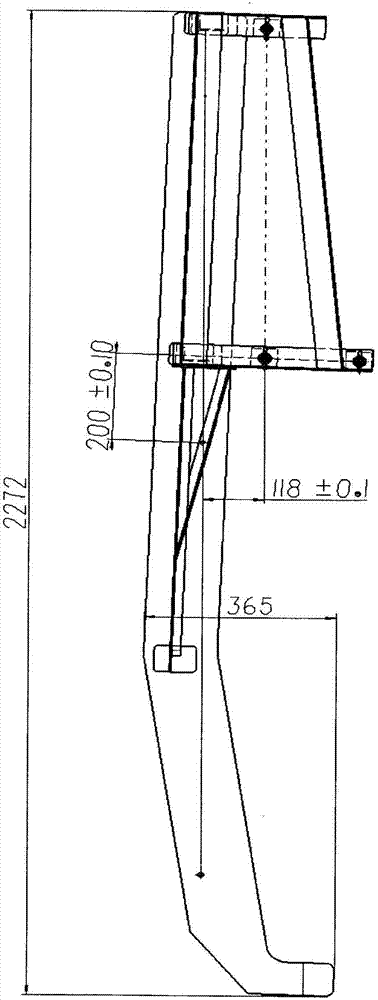

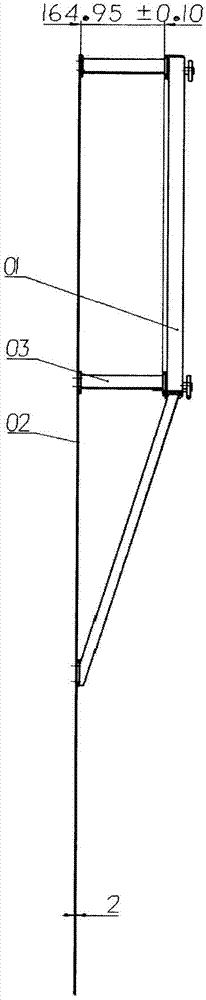

[0017] 1) Use the original 2 holes of the model as the reference hole and add 1 hole as the position measurement hole of the model. The holes of the model and the frame have relative position dimensions of 200±0.1, 118±0.1, 164.95±0.1, and respectively Set to TB4, TB5 and TB6;

[0018] 2) Three holes are drilled by numerical control at three different positions on the frame as the reference holes for establishing the reference coordinate system, and are set as TB1, TB2 and TB3 respectively;

[0019] 3) Set a bushing on the hole of TB1-TB6, and the tool ball of the laser tracker is installed in the bushing, and the ground passing through the bushing is attached to the upper surface of the hole, such as Figure 4 As shown, thus ensuring that the tool ball is installed vertically to the upper surface of the hole;

[0020] 4) In the theoretical state, TB1-TB6 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com