A safety monitoring method for embankments based on adaptive feedback vibrating wire sensors

A vibrating wire sensor and safety monitoring technology, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of short vibration duration of steel strings, difficult signal pickup, accelerated aging of steel strings, etc., to reduce time and accuracy Hitting, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0028] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

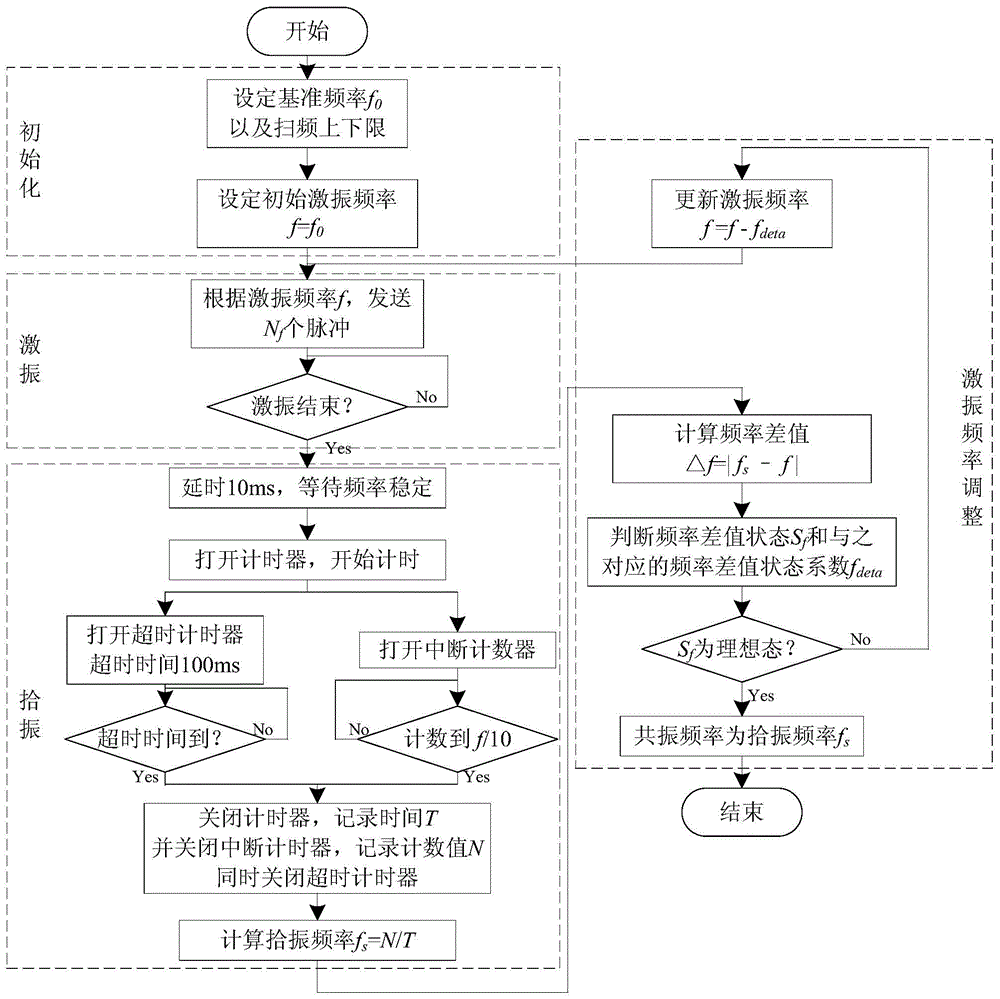

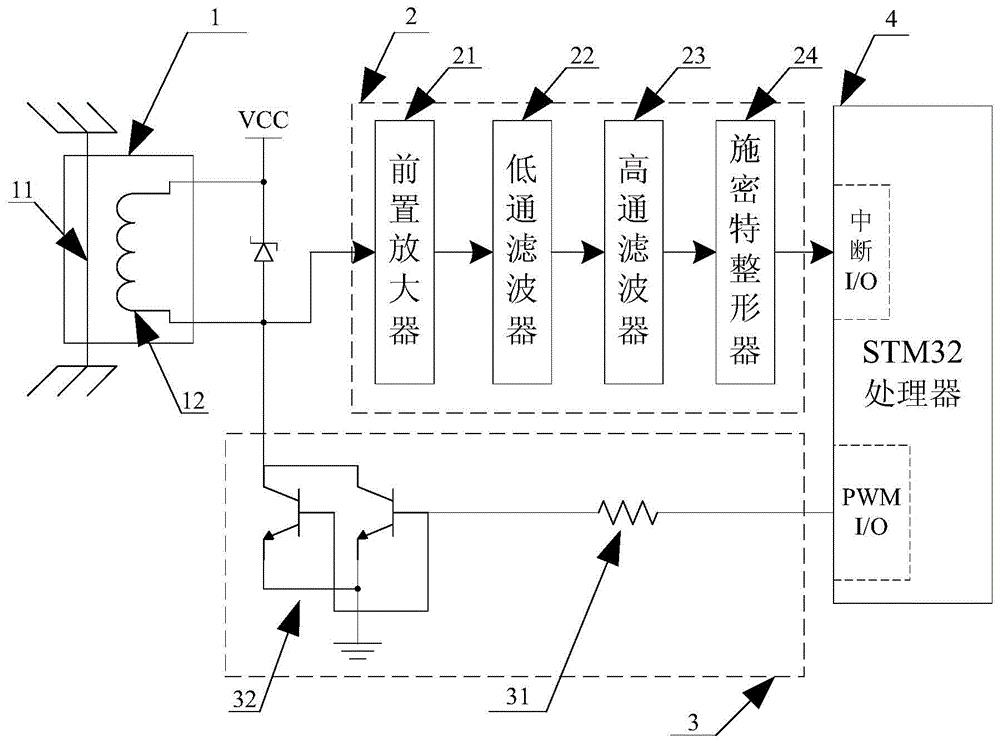

[0029] Such as figure 1 As shown, a dam safety monitoring method based on adaptive feedback vibrating wire sensor, the steps are:

[0030] (1) Initialize, set the reference frequency f of the initial state of the vibrating wire sensor 0 , frequency upper limit f top and frequency lower limit f bottom . Since different vibrating wire sensors have different working principles, the changing direction of the steel string after being stressed is also different. According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com